I believe that everyone is no stranger to stone. As a building material, stone has a long history of application. Stone can be seen everywhere in our lives, and there are stone figures on roads, parks, squares, and building wall decorations.

Stone is divided into natural and artificial stone, in the formal input to the construction project, stone needs to be processed, and good processing technology can fully reflect the decorative effect of stone and its performance.

What Kinds of Stone Processing Machinery Are There?

According to the different processing requirements of stone, more and more different stone processing equipment appear in the market. The following are common stone processing types of equipment.

Water-Jet Cutting Machine

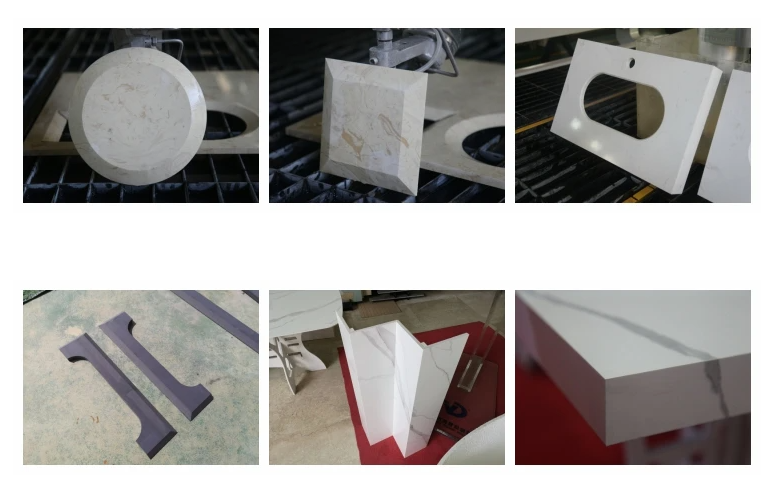

In terms of the stone-cutting process, a water jet cutting machine is a good choice. 5 axis CNC waterjet, 3 axis CNC waterjet, or other types of waterjet cutting machines have the ability to cut a wide variety of materials, providing a high-precision, environmentally friendly, and cost-effective cutting process for many stone processing industries and factories.

The water jet cutting machine can realize plane cutting and 3D cutting to ensure that the processing meets the design requirements. Arc plate cutting and spiral blade cutting can be easily achieved by a water jet cutting machine.

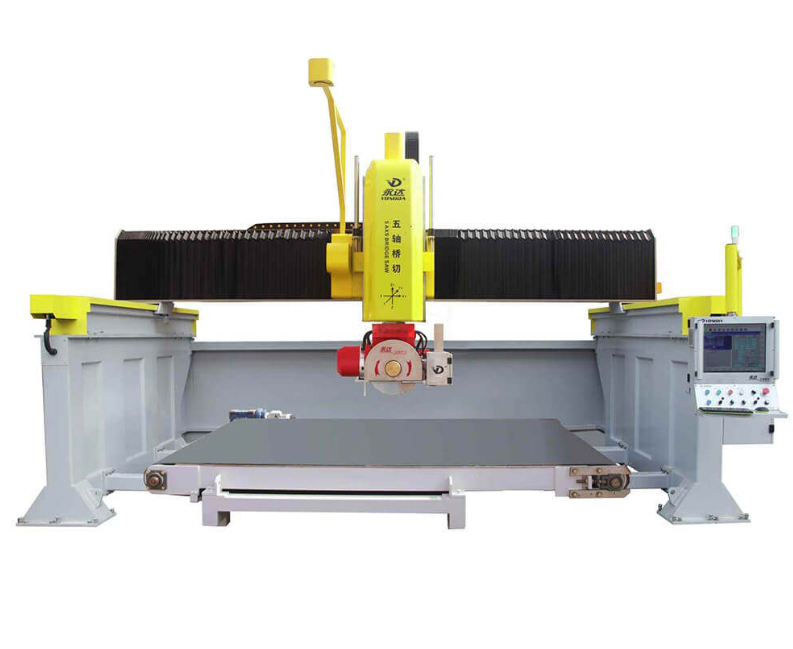

Bridge Cutting Machine

The bridge cutting machine is a cutting machine for cutting natural stone, granite, marble, and ceramics, with the advantages of high precision, high speed, and high efficiency.

The bridge cutting machine is an intelligent cutting machine designed to meet the diverse processing needs of stone enterprises, which ensures professional cutting quality and is an indispensable machine for stone processing companies.

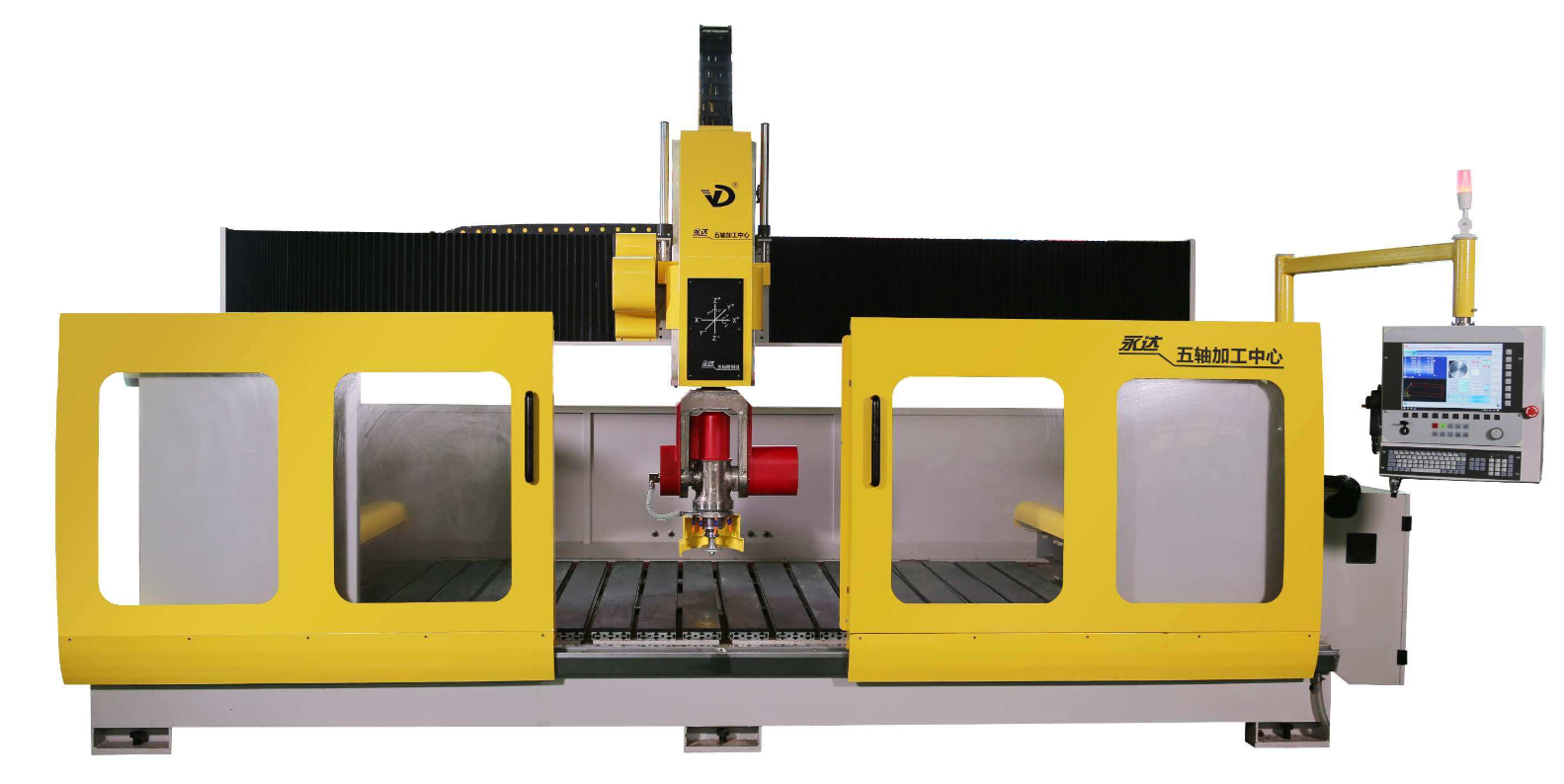

Stone CNC Machine Center

Stone CNC machining center is one of the modern processing methods. A CNC machining center(5 axis CNC bridge cutter, 4 axis CNC bridge cutter) is an advanced manufacturing machine that can perform a variety of machining operations with high precision, high quality, and high surface finish, allowing one machine to meet a wider range of machining needs.

CNC machining centers can be used in a variety of materials, specifically for complex engravings such as various stones, sintered stones, ceramic kitchen countertops, countertop edges, and sometimes even microcrystalline and steel.

5 Axis CNC Bridge Saw for Sale

Ceramic Slab Machine

With the development of modern technology, professional ceramic slab machines are required to process ceramic slabs. Multifunction ceramic large plate cutting machine, mainly used for deep processing of ceramics, such as grinding, chamfering, cutting, etc.

Commonly used ceramic slab processing types of equipment are ceramic tile chamfering machines, ceramic tile slot machines, ceramic tile notching machines, ceramic tile processing machines, grinding and polishing machines, and so on.

18 Heads Ceramic Slab Chamfering Slotting Machine

Grinding & Polishing Machine

Grinding and polishing machines are commonly used for stone and ceramic sample preparation. Grinding and polishing create a flat, uniform surface.

Grinding and polishing equipment provides consistency, reproducibility, and the true structure of the sample. The stone treated by the Grinding & Polishing Machine (kitchen worktop edge polishing machine, ceramic arc edge polishing machine, etc)restores the natural beauty of the stone while solving the problem of stone fall and improving the overall effect of the stone decoration.

Engraving Machine

A stone engraving machine is a device for engraving (pattern or text) on natural stone, glass, and ceramics.

Stone engraving machine processing can greatly shorten the product development cycle and provide a shortcut for new product development, product improvement, and re-formulation.

Other Ceramic Stone Machines

Stone Scanner

The stone scanner scans the stone slab and saves it into the system according to the actual stone size. Images captured by stone scanners have realistic textures and precise layouts.

Replacing thick samples with scanned images, capturing high-quality images, and printing stone catalogs are ideal for stone companies to preserve stone information. Buyers can select stones online based on scanned pictures, saving the cost of spot checks.

There are a variety of other ceramic stone machines available that can assist with cutting, polishing, shaping, and finishing ceramic materials. Depending on the specific needs of the project, one or more stone processing or other ceramic stone machines may be required to achieve the desired result.

When selecting a stone processing machine, it is essential to consider factors such as the type and thickness of the material being worked on, the level of precision required, the desired finish, and the overall scale of the project. Additionally, it is important to consider factors such as ease of use, maintenance requirements and cost when making a decision on which machine to invest in.

Conclusion

Yongda is committed to the design, manufacture, and sales of deep processing equipment such as stone, ceramics, and glass, which improves the machinability of stone and provides customers with more control and higher efficiency.

No matter what kind of stone processing equipment you need, YONGDA can provide advanced solutions for your fabrication or production needs.