Categorys

Hot Product

AC 5 Axis Waterjet Cutting Machine

Advantages of AC 5 axis CNC waterjet head:

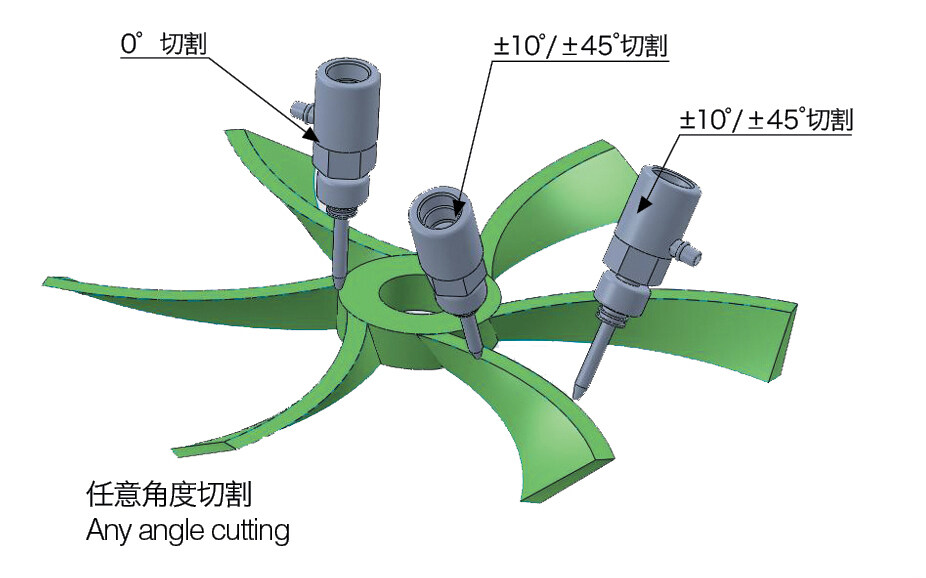

1. 5 axis CNC waterjet cutting machine adopts AC axis design, real 5 axis (X. Y. Z. A.C) move.

2. Structure more tight for the Waterproof and dustproof. electrical wiring has a tidier and more clear layout.

3. All spare parts are processed by Japanese high precision CNC, ensure high accuracy of the 5 axis CNC waterjet.

4. 5 axis CNC waterjet cutter adopts international high-end brand servo motor and servo driver to make the control accuracy higher.

5. Reasonable design, evenly the force, effectively improve the water jet operating life and reliability.

YONGDA AC 5 AXIS CNC Waterjet, a new generation waterjet improved on the basis of AB 5 AXIS with 15 years manufacture experience, a high-end brand waterjet in China which launched into the market successfully and maturely. YONGDA AC 5 AXIS CNC waterjet head is another solution for the high accuracy requirement of the water cutting, it can realize plane cutting and 3D cutting on 3 axis table and make sure meet the design requirement in one time processing.

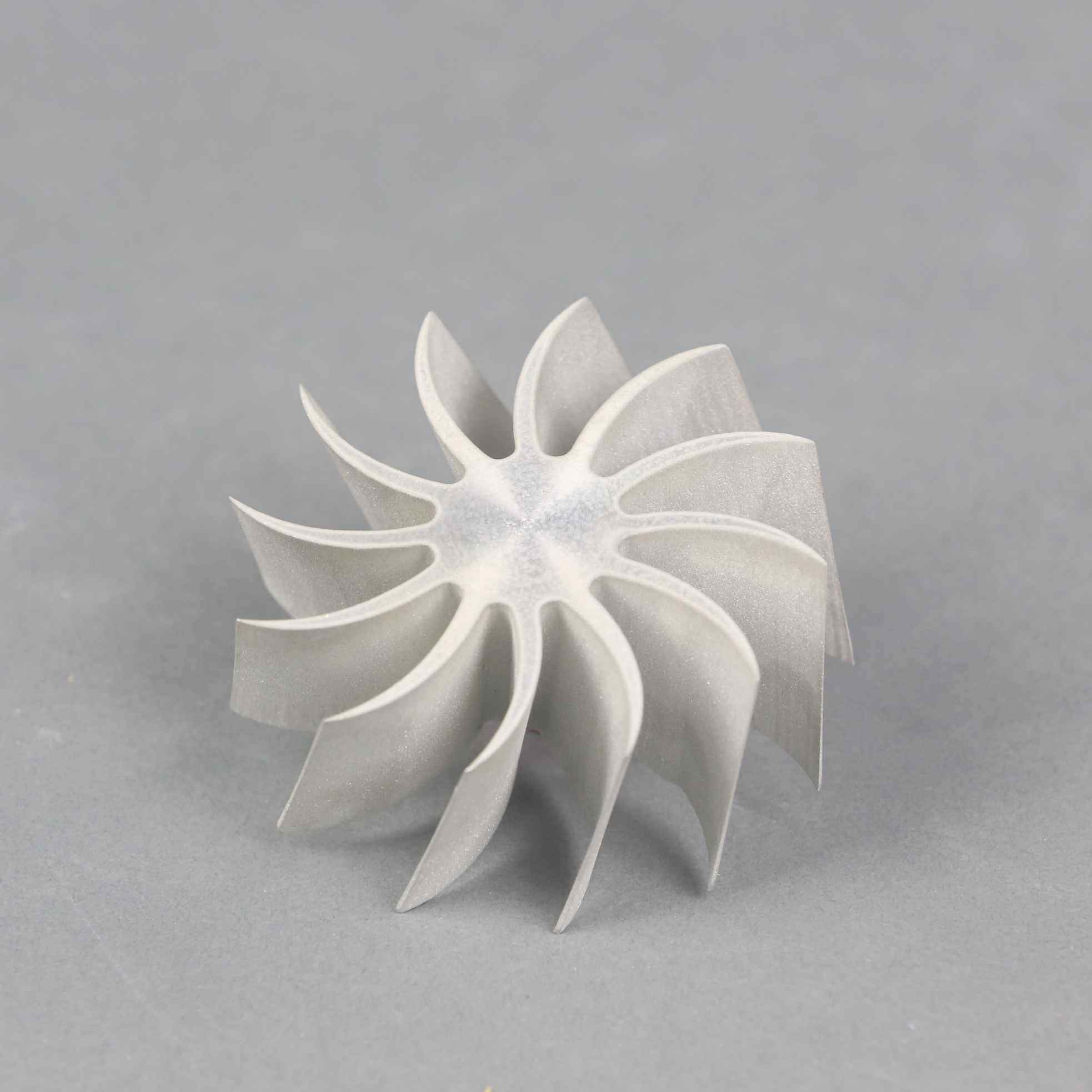

It easily achieves arc plate cutting, cylinder cutting, spiral leaf cutting ... make impossible possible. AC 5 AXIS CNC water jet cutting head can cut arbitrary curve and arbitrary angle, curve and angle changing is controlled by computer which make it more stable.

Waterjet Inclined Cutting

Waterjet cutting is a versatile machining process used to cut a wide range of materials using a high-pressure stream of water mixed with abrasive particles. Waterjet inclined cutting refers to the process of cutting material at an angle other than perpendicular to the surface. This technique is often employed when precise angled cuts or bevels are required in various industries, including manufacturing, aerospace, automotive, and construction.

Here are some key points to consider when it comes to waterjet inclined cutting:

Angle Adjustment: To perform inclined cutting, the waterjet cutting machine can be equipped with a tilting head or nozzle that can be adjusted to the desired angle.

Versatility: Inclined waterjet cutting can produce complex shapes and contours with ease, making it useful for creating parts with beveled edges, tapered cuts, or parts with intricate geometry.

Waterjet inclined cutting is valuable in applications where traditional cutting methods might be impractical or less precise. It allows for the creation of complex parts and components with angles and bevels that meet specific design requirements.

5 Axis Waterjet for Sale

Looking for a waterjet cutting machine for sale? The many advantages of waterjet cutting machines will bring benefits to your production line.

5 Axis Waterjet Cutting Machine Motion System: The machine's 5-axis capability allows for movement along the X, Y, and Z axes, as well as rotation around the A and B axes. This versatility enables the cutting head to reach and cut complex angles, contours, and bevels in three-dimensional workpieces.

Material Versatility: A 5 axis waterjet cutting machine can effectively cut a wide range of materials, including metals (such as steel, aluminum, and titanium), composites, glass, stone, ceramics, rubber, plastics, and more. The waterjet's cold-cutting process minimizes heat-affected zones and prevents material distortion.

Cutting Speed and Accuracy: AC 5-axis waterjet cutting machines are known for their high cutting speeds, allowing for efficient production and reduced turnaround times. The precision and accuracy of these machines ensure consistent and clean cuts, minimizing the need for secondary finishing operations.

Environmentally Friendly: Waterjet cutting is considered an environmentally friendly cutting method. The process uses only water and abrasive materials, eliminating the need for harmful chemicals or gases. Additionally, the water used in the cutting process can be recycled and reused, minimizing water consumption.

Cost Considerations: AC 5-axis waterjet cutting machines are advanced and precise cutting systems, and their cost can vary significantly based on the machine's features, brand, and capabilities. The upfront investment is higher compared to traditional cutting methods, but the versatility, precision, and efficiency of these machines can result in long-term cost savings.

The AC 5-axis waterjet cutting machine offers increased flexibility and precision compared to traditional 3 axis waterjet cutting machines. It enables manufacturers to create intricate designs, complex shapes, and beveled edges with ease. Its application spans various industries, including aerospace, automotive, architecture, manufacturing, and more, where precision cutting of materials is crucial.

In summary, an AC 5-axis waterjet cutting machine offers advanced capabilities for the precision cutting of various materials, allowing for intricate designs and complex shapes. Its versatility, accuracy, and non-heat generating process make it a preferred choice for industries that require high-quality cuts and fine details in their manufacturing processes.

Yongda Waterjet

When considering waterjet cutting machine manufacturers and waterjet cutting machine suppliers, it's important to evaluate factors such as the supplier's reputation, experience in the industry, customer reviews, warranty and support services, and ability to provide customized solutions based on your specific needs. This will help you make an informed decision and select a supplier that best aligns with your requirements and budget.

Looking for CNC water jet cutting machine manufacturers or 5 axis waterjet for sale? Here you can find a suitable one. YONGDA water jet design concept: high accuracy, high efficiency, energy saving, simple maintenance, easy operation, waterproof, dust proof etc. Spare parts are processed by advanced imported equipment, 5 axis head's dynamic accuracy is tested by super high precision instruments, the processing equipment, instruments and precision of resetting reach the leading level of the country. YONGDA water jet makes you feel more stable, more reliable and more satisfied.

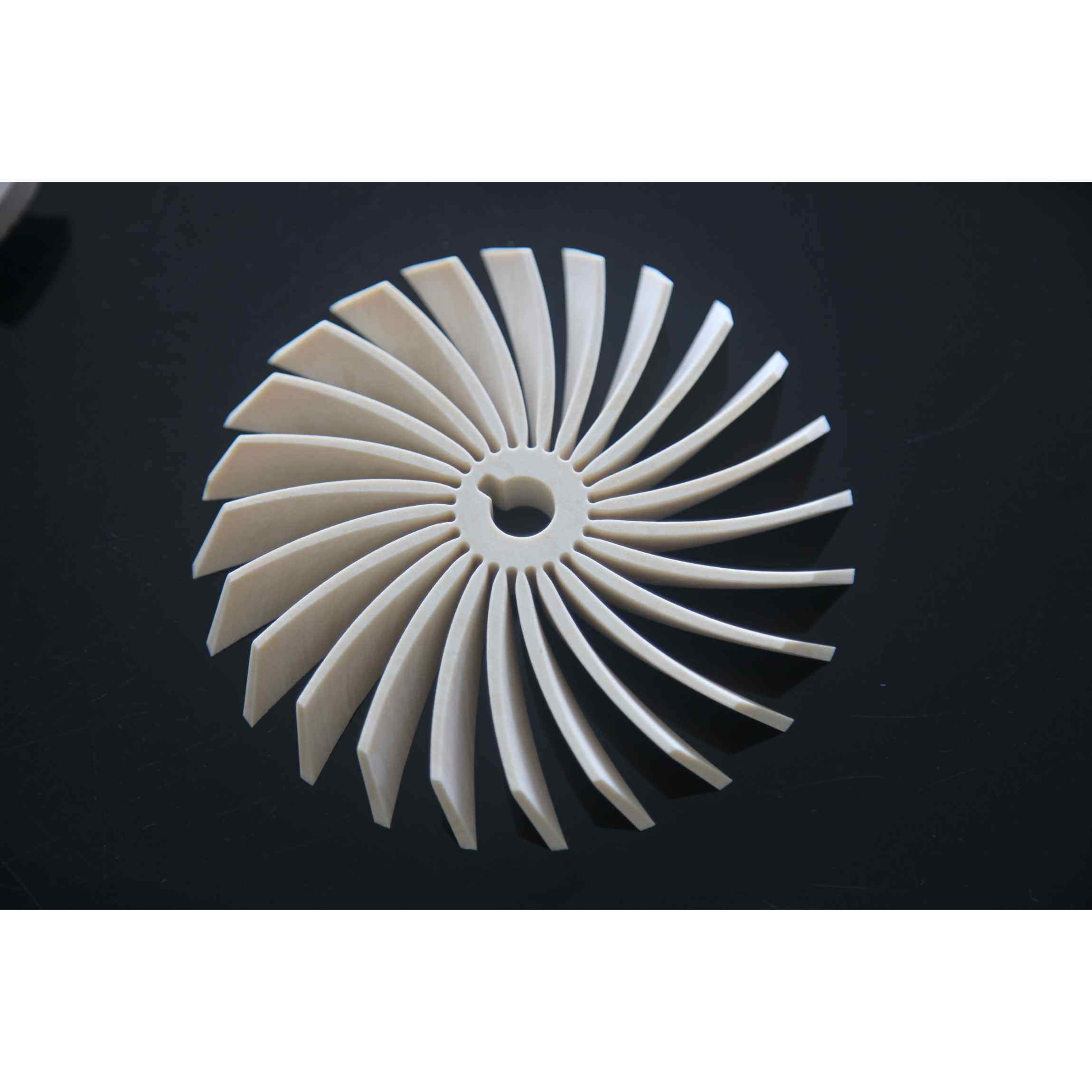

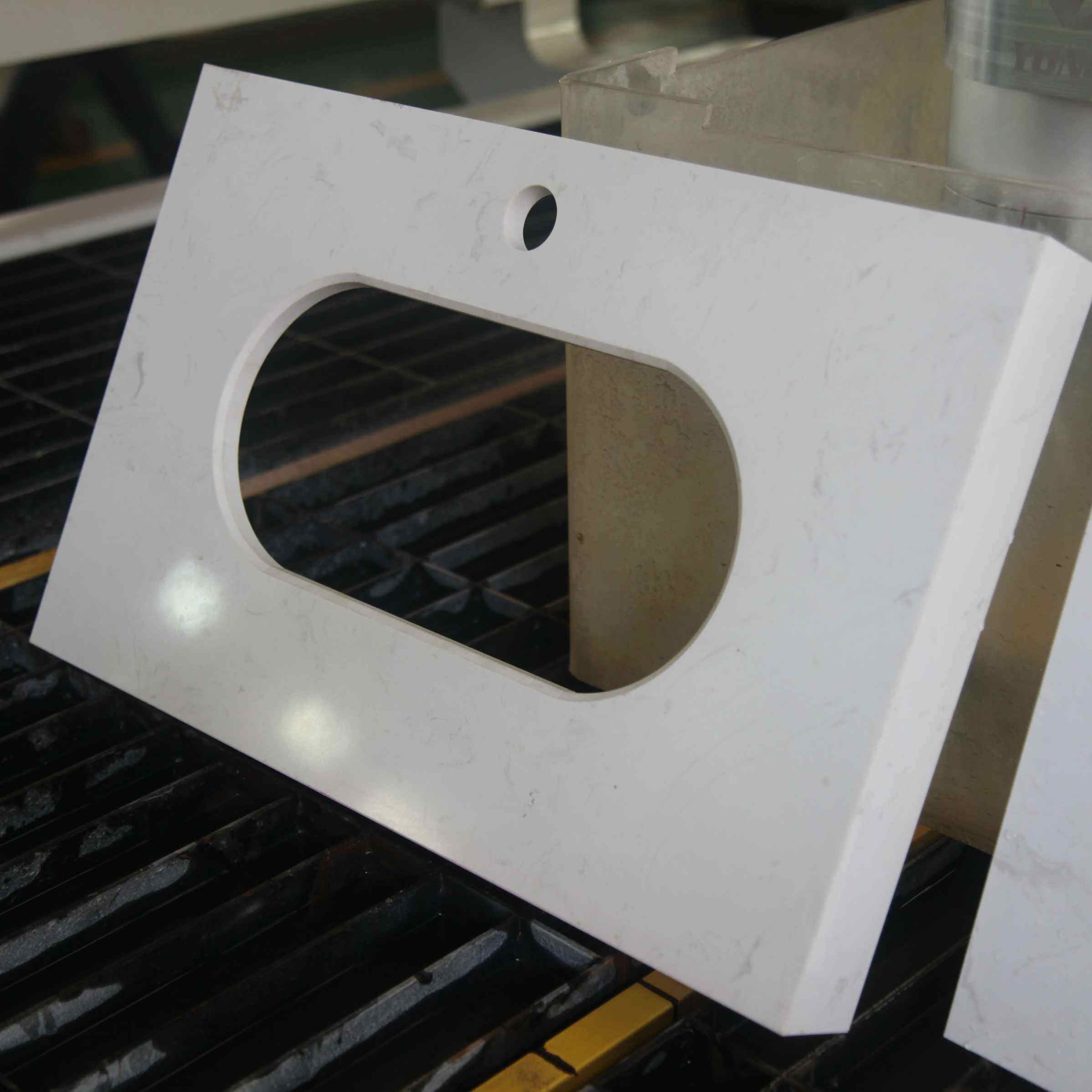

SAMPLE SHOW: 45° CUTTING, MITRE

APPLICATION: WASHING TOP MITRE, COUNTERTOPS MITRE, KITCHENTOPS MITRE

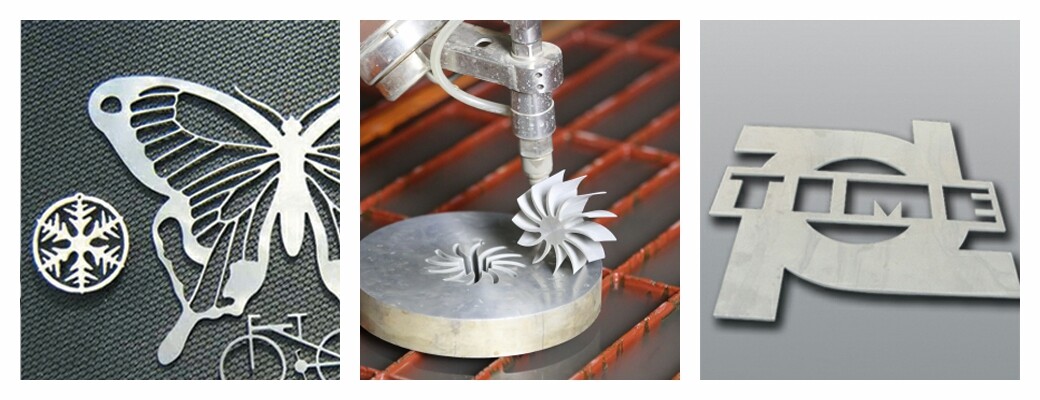

SAMPLE SHOW: METAL CUTTING

|

Model |

YD-1212 |

YD-2015 |

YD-2515 |

YD-3015 |

YD-3020 |

YD-4020 |

|

|

Structure |

Flying-arm |

Flying-arm |

Flying-arm |

Flying-arm |

Bridge |

Bridge |

|

|

Cutting table size |

1300×1300mm |

2100×1600mm |

2600×1600mm |

3100×1600mm |

3100×2100mm |

4100×2100mm |

|

|

Stroke |

X-axis |

1200mm |

2000mm |

2500mm |

3000mm |

3000mm |

4000mm |

|

Y-axis |

1200mm |

1500mm |

1500mm |

1500mm |

2000mm |

2000mm |

|

|

Z-axis |

120mm |

||||||

|

A-axis |

±45° |

||||||

|

C-axis |

Limitless rotation |

||||||

|

CNC controller |

AC servo system |

||||||

|

Accuracy |

Cutting |

±0.1mm |

|||||

|

Repeatability |

±0.05mm |

||||||

|

Traverse speed |

6000∕15000mm∕min |

||||||

|

Power supply |

220V∕380V∕415VAC,50∕60HZ |

||||||

Yongda AC 5 Axis waterjet cutting machine is an effective and efficient solution for cutting, offering precision, speed, and accuracy. 5 Axis CNC waterjet cutting machine can be used in many industries such as ceramic, stone, metallic material, glass, etc.