Categorys

Hot Product

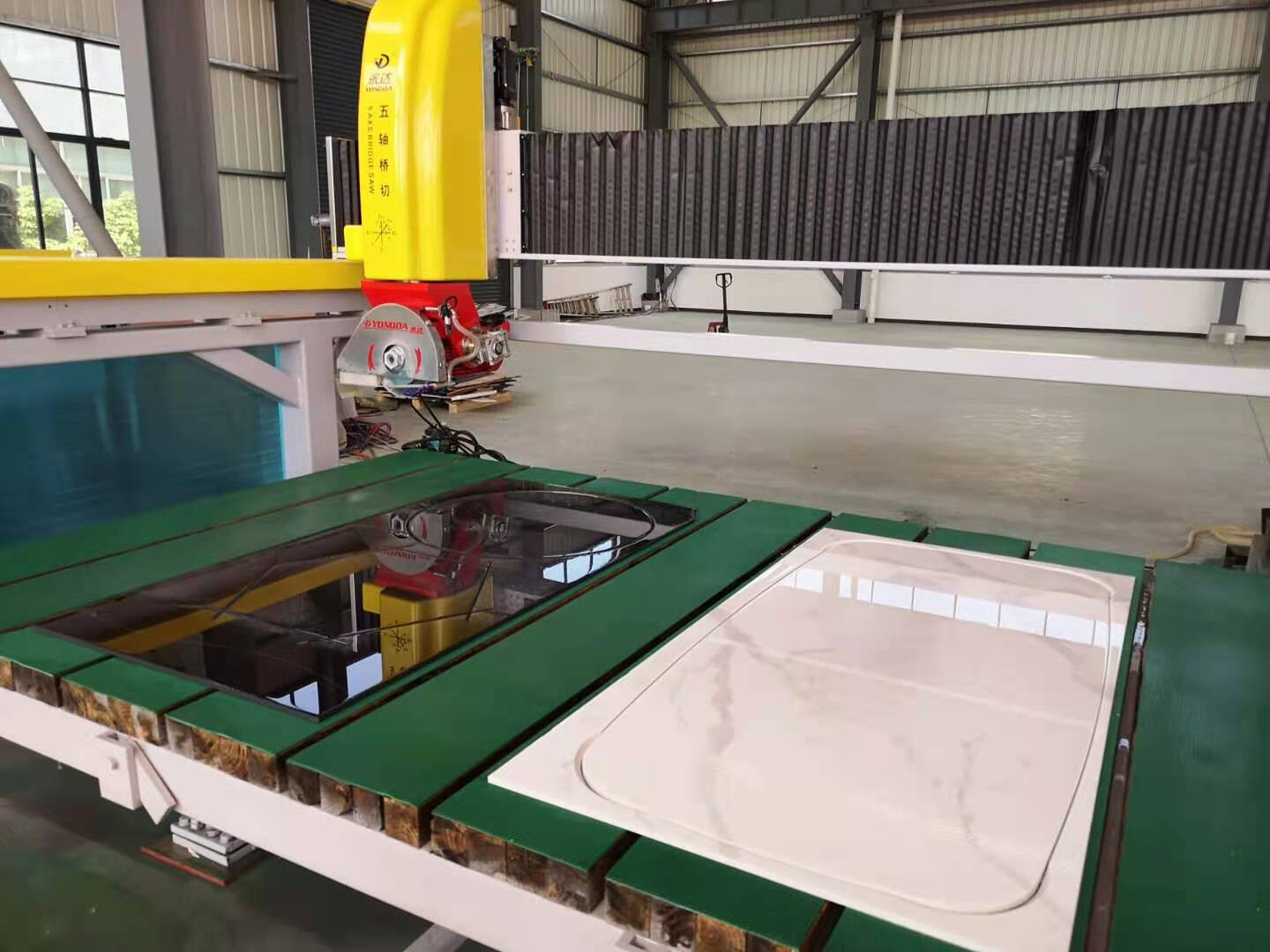

4 Axis Bridge Cutting Machine

YD-3200 4 AXIS S/D

Easy learn, easy control and operation;

Straight line, circular arc, grid, click to cut;

Notching, chamfering, beveling, cut as you like.

4 Axis Bridge Cutting Machine

A 4-axis bridge cutting machine is a specialized piece of equipment used in various industries for cutting and shaping materials with precision and accuracy. It consists of a sturdy bridge-like structure that spans the cutting area and moves along multiple axes to perform various cutting operations.

The "4-axis" refers to the number of axes along which the cutting head can move. These axes typically include the X-axis (horizontal movement of the cutting head), Y-axis (vertical movement), Z-axis (depth or height adjustment), and an additional rotational axis (often referred to as the A-axis) that allows the cutting head to rotate or tilt.

The machine is equipped with a cutting tool, such as a diamond blade or a router, which is mounted on the cutting head. 4 axis CNC bridge cutter can be controlled using computer numerical control (CNC) technology, allowing for precise and automated cutting operations.

By utilizing the multiple axes of movement, 4-axis bridge cutting machine can execute complex cuts, intricate shapes, bevels, chamfers, and other precise operations on the materials. This makes 4 axis bridge saw a versatile tool for industries such as construction, stone, furniture production, prototyping, and artistic projects.

Great CAD/CAM software

1. Simple and intuitive

2. Straight line circular arc, grid, click to cut;

3. Notching, chamfering, beveling, cut as you like

4. Available in a variety shape like cambered shape, engraving, drilling, profiling, etc.

5. Can connecting with scanner, nesting as require, save materials save time

6. Easy to use, convenient and intelligent, high efficiency and low energy consumption

7. Apply international brand CNC control system, servo motor & driver

8. 4 axis bridge cutter can connect with a scanner, nesting as required, save materials saving time

9. With the internet remote diagnosis function, the system parameters can be modified by remote control

|

Items |

Unit |

YD-3220 4 Axis (Standard) |

YD-3220 4 Axis (Deluxe) |

|

X axis stroke |

mm |

3200 |

3200 |

|

Y axis stroke |

mm |

2000 |

2000 |

|

Z axis stroke |

mm |

250 |

500 |

|

A axis stroke |

° |

0~45°(manual adjust) |

0~90°(manual adjust) |

|

C axis stroke |

° |

±185° |

±185° |

|

Dia of disc |

mm |

350-450 |

350-450 |

|

Processing thickness |

mm |

≤60 |

≤60 |

|

System |

|

Taiwan System |

Italy system |

|

Rotation speed of cutting disc |

rpm |

3000 |

3000 |

|

Table size(length x width) |

mm |

3600×2200 |

3600×2200 |

|

Table tilting degree |

° |

0~85° |

0~85° |

|

Spindle power |

kw |

15 |

18 |

|

Total power |

kw |

26 |

35 |

|

Water consumption |

L/min |

40 |

40 |

|

Total weight |

kg |

5000 |

5000 |

|

Outer dimension |

mm |

6000(L)×3900(W)×3100(H) |

5800(L)×3900(W)×3100(H) |

YD series 4 Axis Bridge Saw Machine is an intelligent cutting machine which designed to meet the diversified needs of the processing for the stone enterprises.

The machine is multifunctional, easy operate, processing precise but with low energy consumption. One 4 axis bridge cutter can meet almost all the working.

Requirements and different functions can conversion very fast and convenient.

YD 4 axis bridge saw is a necessary processing equipment for the stone processing enterprises.

The Applications of 4 Axis Bridge Cutting Machine

A 4-axis bridge cutting machine is a specialized tool used in various industries, particularly in the field of manufacturing and fabrication. 4 axis bridge saw offers advanced cutting capabilities and is commonly used in applications such as:

Stone

The 4-axis bridge cutting machine is extensively used in the stone and marble industry for the precise cutting and shaping of stone slabs and blocks. It can create intricate designs, custom shapes, and smooth edges for countertops, sculptures, monuments, and architectural elements.

Construction Industry

In the construction sector, this machine is employed for cutting and shaping large stone or concrete blocks. Bridge saw polygons cutting enables accurate and efficient cutting for constructing building facades, flooring tiles, decorative elements, and other architectural components.

Automotive and Aerospace

The 4-axis bridge cutting machine is utilized in the manufacturing of automotive and aerospace parts. It can cut various materials like aluminum, carbon fiber, and composite materials to create components such as body panels, interior trims, molds, and prototypes.

Furniture Manufacturing

4 axis CNC bridge cutter is employed in the furniture industry for cutting and shaping wooden panels, MDF (Medium-Density Fiberboard), and other materials. Bridge saw edge mitering enables precise and complex cuts required for manufacturing furniture pieces like tabletops, cabinets, and decorative elements.

Signage and Advertising

The 4-axis bridge cutting machine finds applications in the production of signage and advertising materials. It can cut various materials such as acrylic, PVC, foam board, and aluminum composite panels to create letters, logos, and other advertising displays.

Artistic and Craftsmanship Projects

Artists and craftsmen utilize the 4-axis bridge cutting machine for intricate and detailed cutting in their artistic projects. Bridge saw inclined cutting allows them to work with diverse materials like stone, wood, metal, and glass to create sculptures, installations, and decorative pieces.

In summary, a 4 axis bridge saw is a versatile and powerful tool used in various industries for precision cutting and shaping of materials. Its multi-axis control and automation capabilities make it suitable for a wide range of applications, from stone cutting for countertops to metal fabrication for aerospace components. You can find more information about the 4 Axis bridge cutting machine in YONGDA.