--why waterjet can be a best tool for metal cutting?

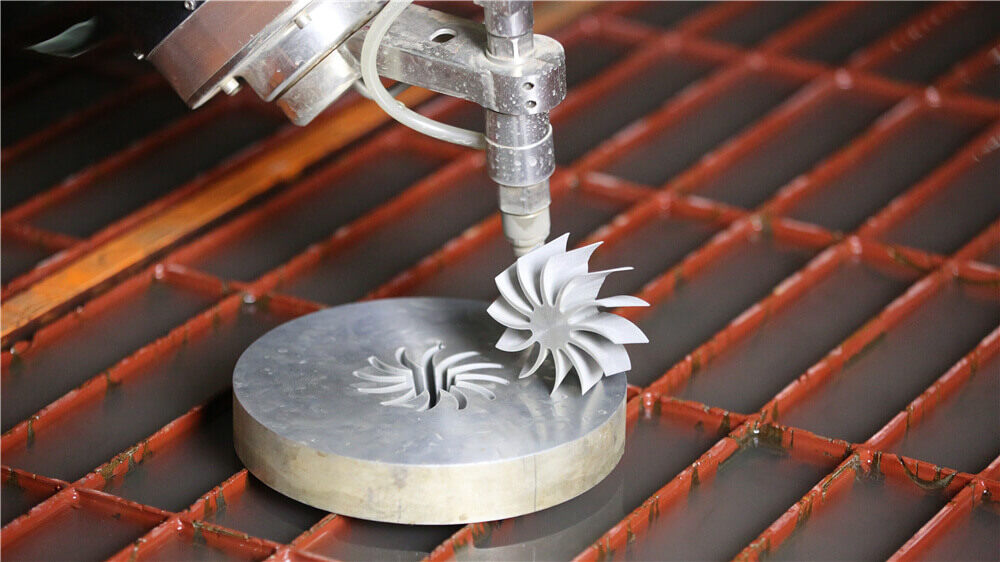

Waterjet cutting, one of the processing method, use the high pressure water combines with abrasive to cutting. The most significant value of the waterjet is that it is cold cutting. The heat generated during cutting will be immediately taken away by the high-speed flowing water, with no thermal effect. Therefore, it is different from laser and plasma, the material is not be damaged by the heat. Also it is fast and flexible so it is a common method in cutting metallic material for example stainless cutting.

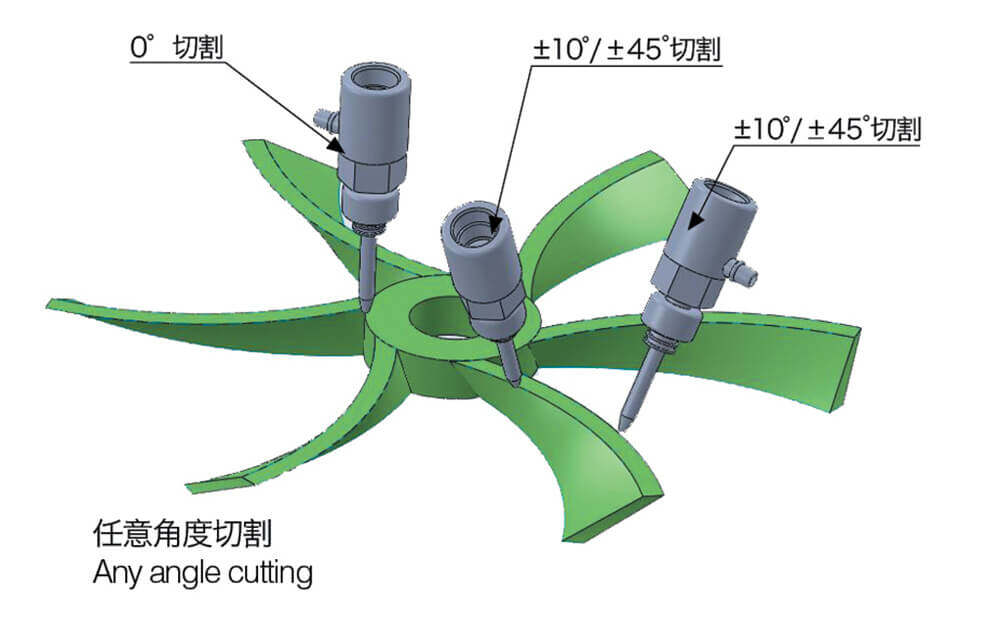

The other advantage is in cutting thickness. Laser and plasma is limited in the thinner thickness. However, waterjet can cut thicker layer. Especially 5 axis waterjet, it can cut different shape and size. Yongda 5 AC axis waterjet cutting machine, adopt AC axis design, realize 5 axis (X,Y,Z,A,C)movement. Easily solve the various cutting demand such as cylinder cutting, spiral cutting leaves and other design shaped. Besides, the work-piece cutting by the waterjet can avoid the secondary processing that can be used for next processing steps directly.