Categorys

Hot Product

Stone Profiling Machine

1.Automatic Tool Correcting Function;

2.Easy and simply to operate,PLC control system, full automatic production;

3.High finish quality and good performance stability;

4.Low processing cost and high production efficiency;

5.The perfect protection device can ensure that the precision components of the equipment in the harsh environment are free from pollution and damage.

In 2000,YONGDA started to invest into developing stone profiling line and achieved in 2002. This is the first automatic stone profiling line in China. From then on, our machine has gained much good evaluation from our largest customers such as Best Cheer, UMGG, KangLi, XiShi, YingLiang etc.

YONGDA YXT-200 line profiling production line has the functions of automatic tool setting, intelligent software control, and remote control,etc. Since the equipment is put into use, it has been well received by the manufacturers.

Easy and simply to operate,PLC control system, full automatic production

High finish quality and good performance stability

Low processing cost and high production efficiency

The perfect protection device can ensure that the precision components of the equipment in the harsh environment are free from pollution and damage.

|

Items |

Unit |

YXT-200Ⅱ/YXT-200 |

|

Nos of shaping wheel |

PCS |

4 |

|

Dia of shaping wheel |

mm |

200 |

|

Nos of polishing wheel |

PCS |

8 |

|

Dia of polishing wheel |

mm |

200 |

|

Working width |

mm |

20~200 |

|

Working thickness |

mm |

15~120 |

|

Working speed |

m/min |

1~4 |

|

Total power |

kw |

85 |

|

Water comsumption |

L/min |

200 |

|

Air consumption |

L/min |

10 |

|

Outer dimension |

mm |

Shaping: 4200×1600×1900 polishing: 5700×1600×1900 |

|

Total weight |

kg |

8000 |

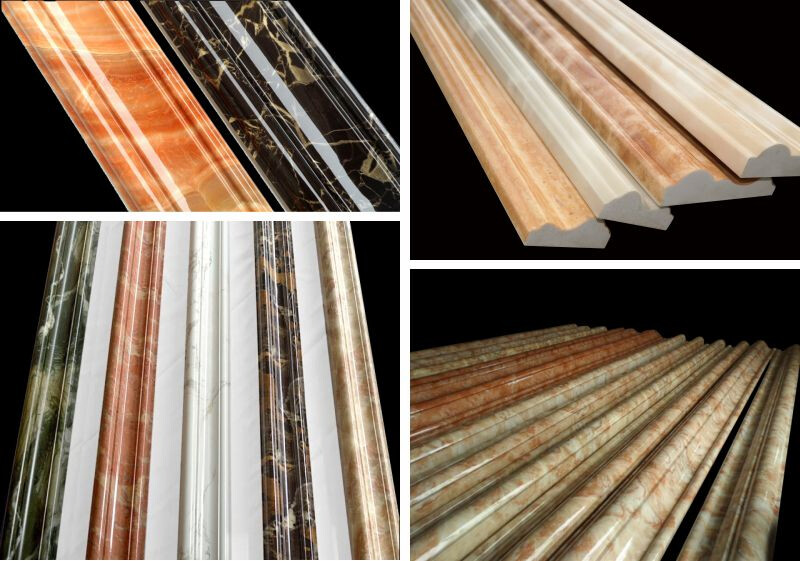

Suitable for stone industry and various materials, like marble, granite, man-made stone and ceramic etc.