Categorys

Hot Product

5 Axis CNC Machining Center

1. Industry-leading programming software, intuitive, fast and easy to learn;

2. International system brand, servo, lead screw and guide rail. High speed, stable and reliable;

3. No need make tool setting, no need adjust tool centre, easy operation;

4.Automatic vacuum fixing and releasing, loading and unloading easily.

5.Multifunctional including engraving, milling, grinding etc;

5 Axis CNC Machining Center

5 axis CNC machining center is a high-tech, high-accuracy stone CNC machine center that specialized in all different kinds of stone and table edge complex carving processing.

5 axis stone CNC machining center uses a five-axis simultaneous control system, also suitable for glass, different kinds of hard material carving processing, etc. Multi-function is the most advantage of this machine such as drilling, blade cutting, edge grinding, chamfering, milling bottom edge, polishing, etc.

The 5 axis CNC machining center adds two additional rotational axes compared to the traditional 3 axis CNC machining center. These extra axes enable the cutting tool to approach the workpiece from various angles and positions, resulting in greater flexibility and the ability to create intricate and precise geometries.

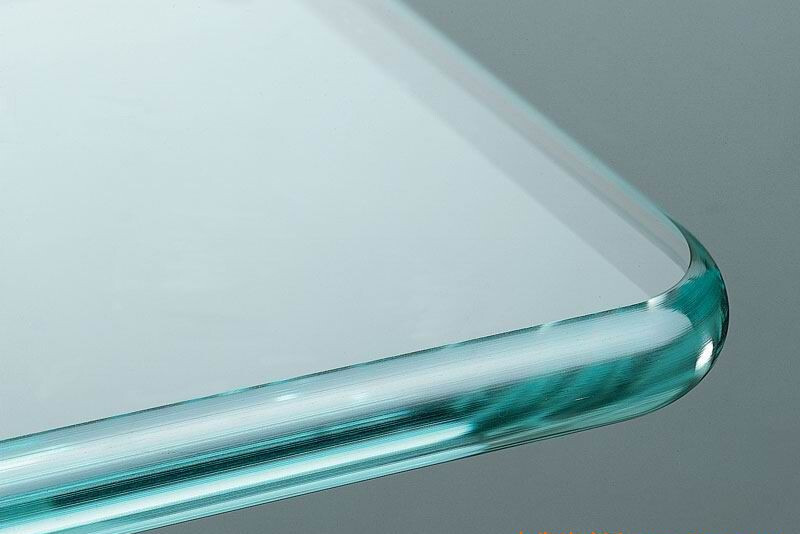

SAMPLE SHOW: different shape and edge

AUTO TOOL-CHANGE SYSTEM

|

Items |

单位 |

CNC5-3020 |

CNC5-4020 |

|

Table size |

mm |

3000×2100 |

3600×2100 |

|

Processing size |

mm |

Grinding edge: 2900×1900 |

Grinding edge: 3500×1900 |

|

Engraving: 2900×2000 |

Engraving: 3500×2000 |

||

|

Carved designs: 2900×1700 |

Carved designs: 3500×1700 |

||

|

Z axis stroke |

mm |

380 |

|

|

C axis stroke |

° |

±200° |

|

|

A axis stroke |

° |

0~90° |

|

|

Max processing thickness of machinable piece (Grinding edge) |

mm |

0~80 |

|

|

Max processing thickness of machinable piece (Plane engraving) |

mm |

0~200 |

|

|

CNC system |

|

Italy operating system |

|

|

Main spindle power |

kw |

15kw |

|

|

Rotation speed of the tool-holder spindle |

rpm |

12000 |

|

|

Tool-store |

nr |

6+6 |

|

|

Air consumption |

L/min |

200 L/min 0.6MPa |

|

|

Outer dimension |

m×m×m |

6000×3800 |

6600×3800 |

5 Axis Stone CNC Machining Center is suitable for stone countertops, kitchentops, glass and stone engraving,

and different kinds of hard material carving processing etc.

Versatile Stone Processing

The 5 axis CNC machining center is a versatile solution for processing various stone applications. It excels in shaping and carving stone countertops, providing precision in dimensions and intricate designs.

Kitchen Top Manufacturing

Specifically designed for kitchen tops, this stone CNC machining center ensures the accurate and efficient production of stone surfaces used in kitchen spaces. The five-axis capability allows for complex contours and detailed edging, meeting the high standards of modern kitchen design.

Glass and Stone Engraving

Beyond countertops, the 5 axis CNC machining center is adept at glass and stone engraving. Whether it's creating intricate patterns on glass surfaces or adding detailed designs to stone materials, the 5-axis system enables precise and artistic engraving.

Hard Material Carving

One of the notable applications of the 5 axis CNC machining center is its proficiency in carving hard materials. It includes processing dense stones and other challenging materials with a level of accuracy and intricacy that would be difficult to achieve with conventional machining methods.

High Precision Processing

The utilization of five-axis technology ensures superior precision in machining. The ability to manipulate the cutting tool along multiple axes allows for the creation of highly complex and detailed shapes, meeting the demands of intricate designs in the stone and hard material processing industry.

In summary, the 5 axis stone CNC machining center is a powerful and versatile tool in the realm of stone processing. Its applications extend from kitchen top manufacturing to glass and stone engraving, showcasing its adaptability in various industries that demand precision, efficiency, and customization.