In contemporary times, stone processing has become integral not only for constructing the core structure of buildings but also for enhancing their aesthetic appeal. An increasing number of consumers are opting for stone, given its versatility in home decoration. The stone is used frequently in the process of decoration. Stone can be seen on cabinet countertops, background walls, and bathrooms.

Stone decorative materials such as marble, quartz stone, granite, etc. are often found in the decoration materials. Once selected, stones undergo a series of processing steps to achieve the desired shape, size, and finish, tailored to the customer's specific requirements. Moreover, proper stone processing techniques can significantly enhance the durability of the stone, thereby increasing its lifespan and utility.

The Importance of Stone Processing

The importance of stone processing cannot be overstated. This procedure allows for customization, ensuring that each piece of stone fits perfectly within its intended setting. From kitchen countertops to bathroom tiles, processed stone is everywhere. It's the silent hero that transforms a house into a home

What Are the Usual Types of Stone Processing?

Sawing Processing

In the process of stone processing, sawing machines are utilized to shape granite and other stones into semi-finished products like rough slabs, strips, and blocks. These are stored until they're ready for further processing.

Cutting Processing

For stone processing, cutting is a crucial step where a cutting machine is used to slice the stone according to the required specifications and dimensions, yielding the desired shape.

Chiseling Processing

By chiseling, chopping, trimming, grinding, and other methods to process the stone rough into the required product specifications. Common engineering stone processing surfaces are the litchi surface, longan surface, pineapple surface, natural surface, etc.

Chiseling Processing

Chiseling is an art form within the world of stone processing. It involves various techniques like chopping, trimming, and grinding to transform a rough stone into a product with precise specifications. From creating surfaces resembling litchi, longan, pineapple, to a natural finish, it's a testament to the transformative power of stone processing.

Singeing Processing

In the singeing process of stone processing, the stone surface is exposed to a high-temperature flame from industrial equipment. This causes the iron elements within the stone to oxidize, resulting in a distinct, textured effect. Spray burnishing processing effect on the stone has a certain protective effect, including the creation of a kind of antique surface, that is, burning surface stone.

3 Axis CNC Waterjet Cutting Machine

Grinding and Polishing

Stone processing involves transforming a rough stone into a refined product through a series of steps. This includes initial grinding and polishing, followed by semi-fine grinding, fine grinding, and additional polishing, executed meticulously with processing equipment and manual craftsmanship.

Auxiliary Processing

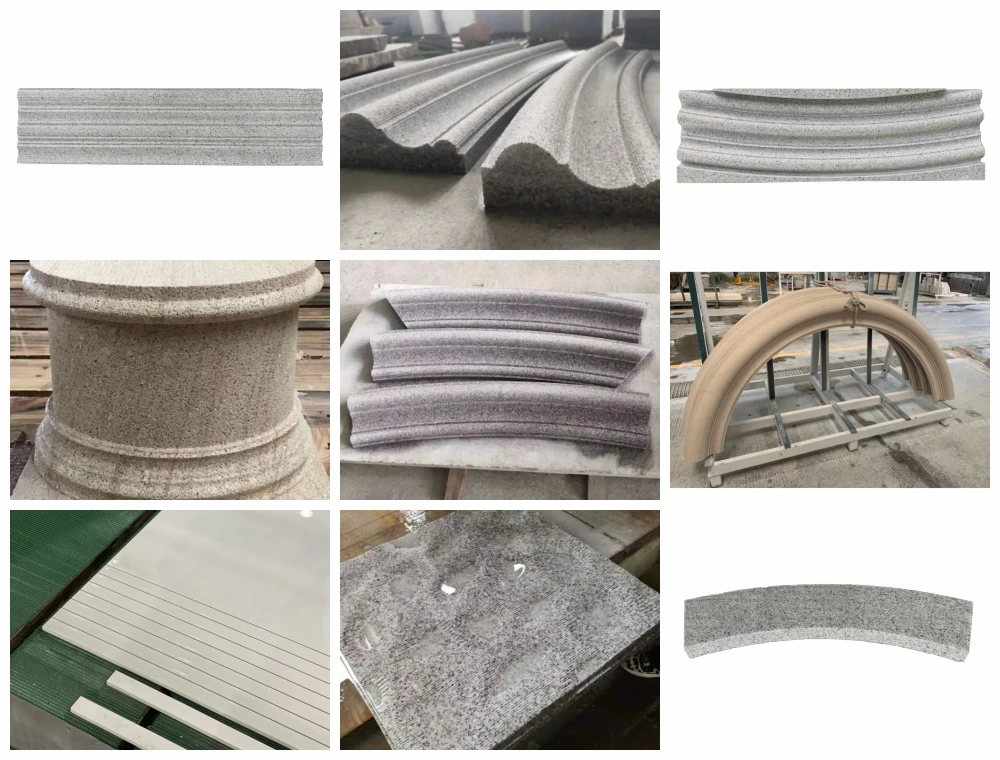

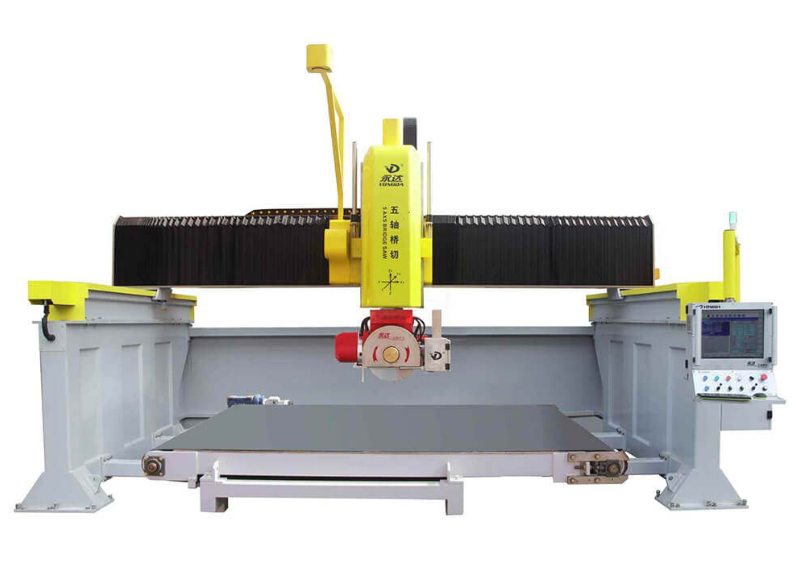

Once cut and polished, the stone undergoes further customization as per the buyer's requirements. This could include edging, chamfering, drilling holes, and creating slots. This process requires the use of machines capable of edging and chamfering, such as 5 axis bridge cutting machine, 5 axis CNC bridge cutter, ceramic slab cutting machine.

The Final Steps in Stone Processing

The final steps in stone processing involve careful inspection and repair. The stone is first cleaned, then dried and inspected. Only those that meet the quality standards are packed and stored for distribution, ensuring each piece that leaves the factory is nothing short of perfect.

Conclusion

Marble, granite, slate, and other stones are widely used in engineering construction, hand-carving, decorative design, and art industries. These stones can be put into use after processing.

The intricate process of stone processing relies heavily on specialized machinery, including waterjet cutting machines, bridge cutting machines, CNC engraving machines, and grinding & polishing machines. These machines play a crucial role in transforming raw stone into a myriad of designs and applications, enabling us to appreciate the versatile beauty of processed stone.

Yongda is able to provide innovative and cost-effective solutions for Chinese stone companies. Please browse our product list to find your ideal one and contact us promptly.