Categorys

Hot Product

1. The 3 axis CNC waterjet cutting machine has omnipotent cutting functions. It is used for any plane curve cutting.

2. Reinforce machine tool assures the cutting head does not vibrate during fast moving. The operation is steady, with fast cutting speed and high precision.

3. The ball screws and rails are provided by renowned Germany manufacturers. The X and Y axis apply unique oil immersion lubrication, together with water-proof and dirt-proof structures. So as to assure the processing precision of the machine and prolong the life of the screws and guide rails furthest.

4. The cutting head is equipped with reliable pneumatic high pressure water switch, which enhances the efficiency.

5. The unique sand valve design enables smoother flow of the sand, more convenient cleaning. And the prevention of the water leakage.

6. The stainless steel protection cover is dirt-proof, water-proof, rust-proof, erosion-proof, and convenient for cleaning, keeping the work table bright all year.

7. There is Flying-arm or Bridge type of structure for working table, with Step System or AC Servo System for CNC controller.

There are several reasons why you may choose to use a 3 axis CNC waterjet cutting machine for your cutting needs:

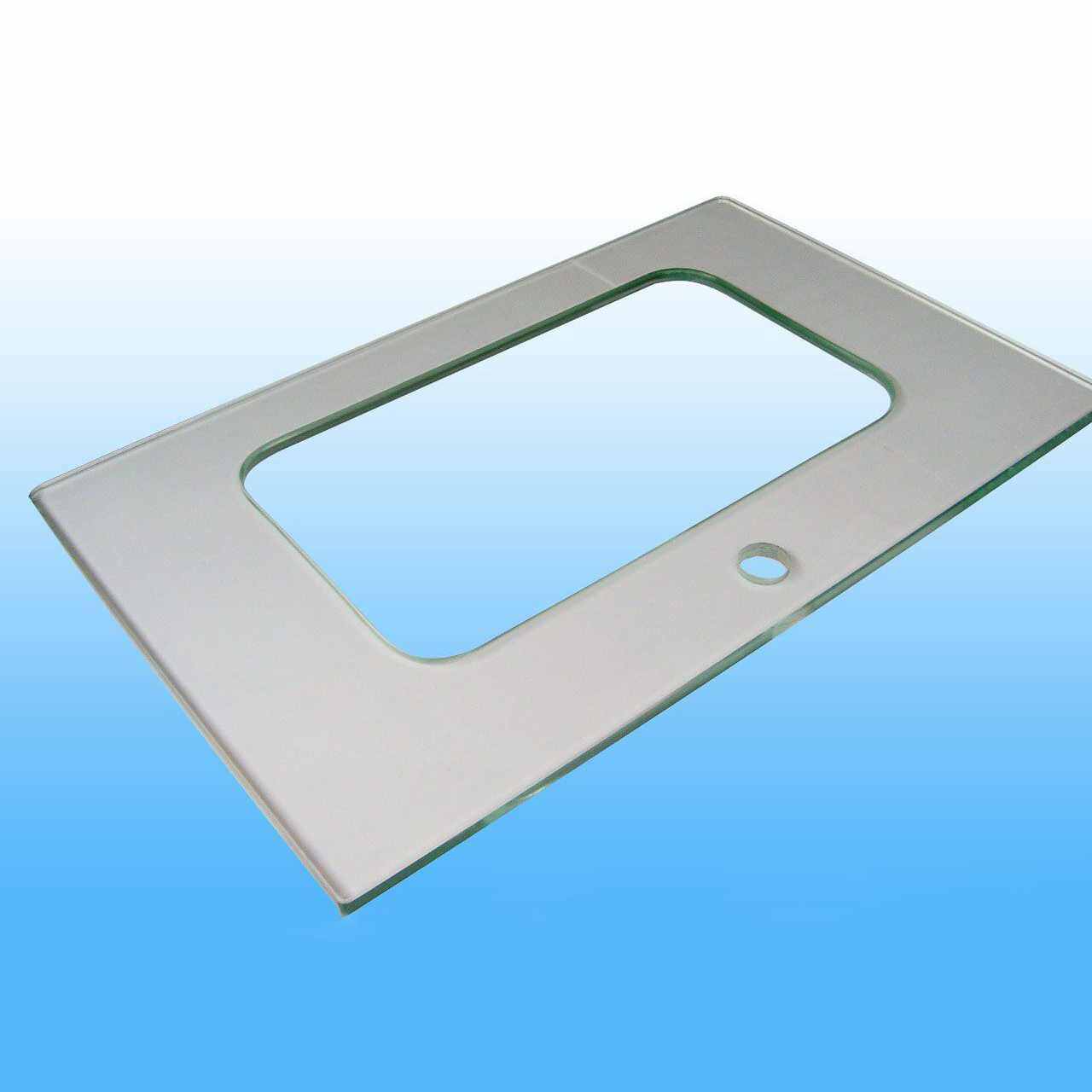

Versatility: 3 axis CNC waterjet machines can cut a wide range of materials, including metal, stone, glass, composites, and more. This makes them a versatile choice for a variety of industries, from automotive to aerospace to art.

High-precision: 3 axis CNC waterjet machines offer a high degree of accuracy. This level of precision is crucial in industries where quality and accuracy are essential.

High-speed: CNC waterjet cutting machines are also known for their high-speed cutting capabilities. They can quickly and efficiently produce a high volume of parts.

Environmentally friendly: Unlike traditional cutting methods that generate a significant amount of waste and emissions, CNC waterjet cutting machines use water and an abrasive to cut materials. This process produces minimal waste, making it an environmentally friendly option.

Minimal setup time: With a CNC waterjet cutting machine, there is minimal setup time required. Once the machine is programmed, it can begin cutting immediately, which saves time and increases efficiency.

Flexibility: CNC waterjet cutting machines are highly flexible and can produce a wide range of designs and shapes, from simple to complex. This flexibility allows for customization and the production of unique and innovative parts and designs.

In summary, a 3 axis waterjet cutting machine and 5 axis CNC waterjet cutting machine can offer versatility, high precision, high speed, environmental sustainability, minimal setup time, and flexibility, making it an excellent choice for a wide range of industries and cutting needs.

|

Model |

YD-1212 |

YD-2015 |

YD-2515 |

YD-3015 |

YD-3020 |

YD-4020 |

|

|

Structure |

Flying-arm |

Flying-arm |

Flying arm |

Flying-arm |

Bridge |

Bridge |

|

|

Cutting table size |

1300×1300mm |

2100×1600mm |

2600×1600mm |

3100×1600mm |

3100×2100mm |

4100×2100mm |

|

|

Stroke |

X-axis |

1200mm |

2000mm |

2500mm |

3000mm |

3000mm |

4000mm |

|

Y-axis |

1200mm |

1500mm |

1500mm |

1500mm |

2000mm |

2000mm |

|

|

Z-axis |

3-axis 130mm |

||||||

|

CNC controller |

Step system for 3 Axis |

||||||

|

Accuracy |

Cutting |

±0.1mm |

|||||

|

Repeatability |

±0.05mm |

||||||

|

Traverse speed |

6000∕15000mm∕min |

||||||

|

Power supply |

220V∕380V∕415VAC,50∕60HZ |

||||||

The application of 3 axis CNC waterjet

The 3 axis CNC waterjet is a high-precision cutting machine that uses a high-pressure waterjet combined with an abrasive to cut a wide range of materials, including metal, glass, stone, ceramic, and composites. Here are some common applications of 3 axis CNC waterjet technology: manufacturing, architecture, sign-making, and artistic applications.

In summary, Yongda waterjet(3 axis CNC waterjet or 5 axis CNC waterjet) has many applications across various industries, from manufacturing to art. Its high precision, speed, and efficiency make it a popular choice for producing intricate designs and complex shapes from a wide range of materials.

Choosing the quality 3 Axis Waterjet Cutting Machine

Investing in the right waterjet cutter is crucial for achieving precise and efficient cutting results.

While cost is an important consideration, it should be balanced with the machine's features, performance, and long-term value.

Evaluate the overall return on investment (ROI) by considering factors such as productivity gains, material savings, reduced downtime, and the longevity of the machine.

By considering these factors, you can make an informed decision and choose a quality 3-axis waterjet cutting machine that aligns with your cutting requirements, offers reliable performance, and provides long-term value.

3 Axis Waterjet Cutting Machine for Sale - Yongda Waterjet

When it comes to investing in a 3-axis waterjet cutting machine, choosing quality waterjet cutting machine suppliers is crucial. The reliability, performance, and support provided by the manufacturer can significantly impact the machine's longevity, productivity, and overall return on investment.

Reputablewaterjet cutting machine manufacturers and waterjet cutting machine suppliers will not only provide a high-performance machine but also be a long-term partner in your cutting operations, contributing to your business's success.

YONGDA is a company dedicated to designing, manufacturing, and sales of deep-processing equipment for stone, ceramic, glass, and metal. YONGDA specializes in producing waterjet machines, bridge cutting machines, CNC machining centers, and edge polishing machines. Choose your suitable stone processing machine at Yongda, improve your production line, and boost sales.