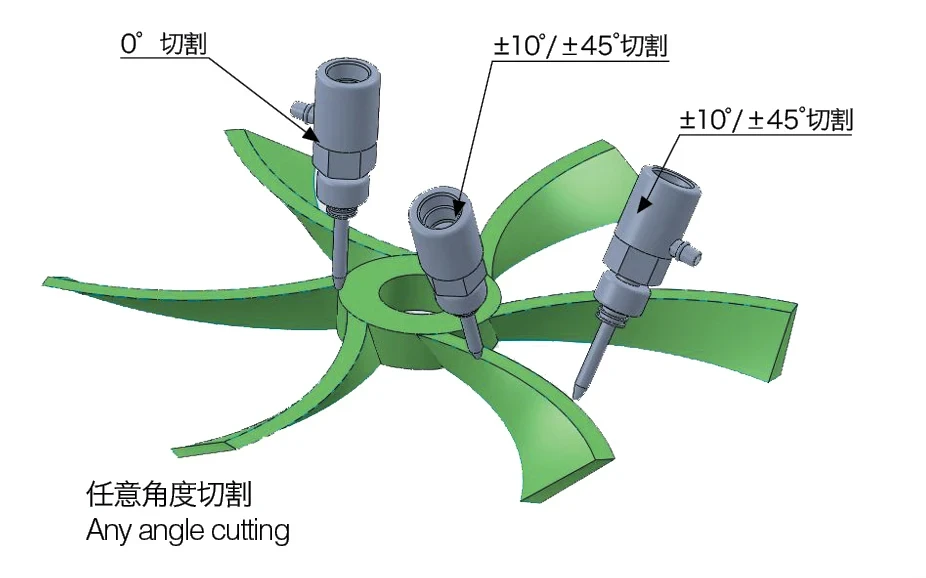

Multifunctional cutting machine - YONGDA AC 5 Axis CNC Waterjet is known for its versatility, making it an ideal tool in industries like ceramics, stonework, metal, and glass.

A kitchen worktable cutting machine is a powerful tool that combines precision, efficiency, and versatility, enabling fabricators to create beautiful and durable countertops.

Stone work cutting machines combine high-speed rotation, precision engineering, and various abrasive elements to achieve smooth and clean cuts.

In comparing 4 axis and 5 axis bridge saws, both have valuable strengths depending on the application.

Looking 5 axis CNC bridge saw for sale? Yongda can be the ideal manufacturer for you. Contact us for more details.

Whether you\'re fabricating countertops, sculptures, architectural elements, or custom stonework, the 5 axis CNC bridge cutter can meet your needs.

Whether you\'re involved in large-scale manufacturing or custom artistic projects, 4 axis bridge saw offers a solution that meets diverse cutting needs.

The precision, efficiency, and versatility of kitchen countertop cutting machines features make them essential for both custom projects and mass production.

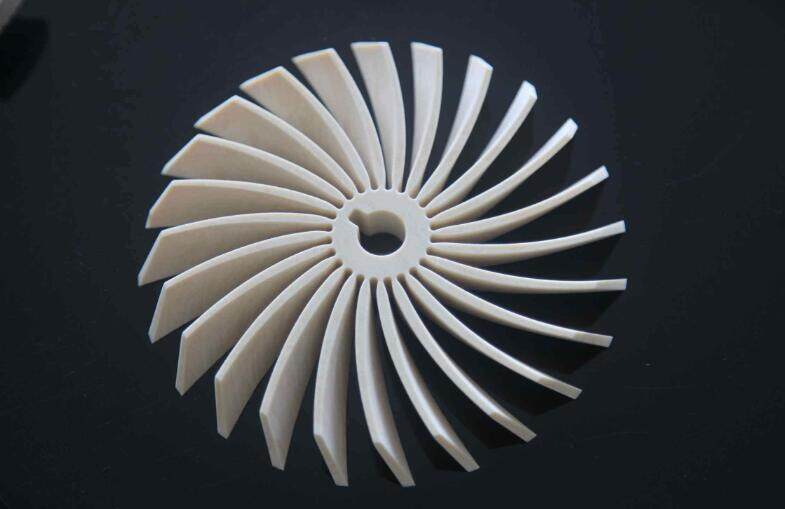

Stone irregular shape cutting involves shaping stones into non-standard forms, which can be essential for construction, landscaping, and artistic endeavors.

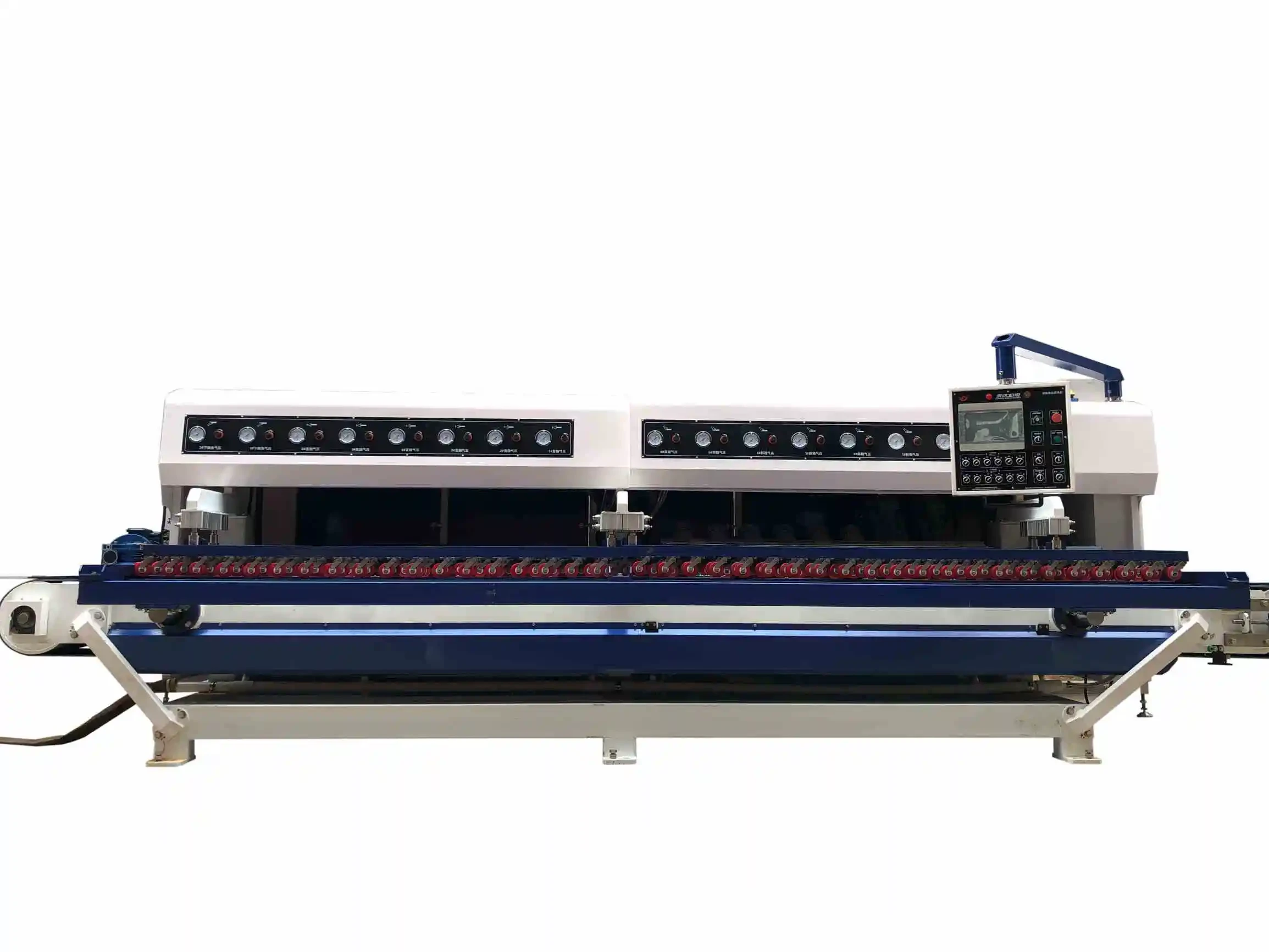

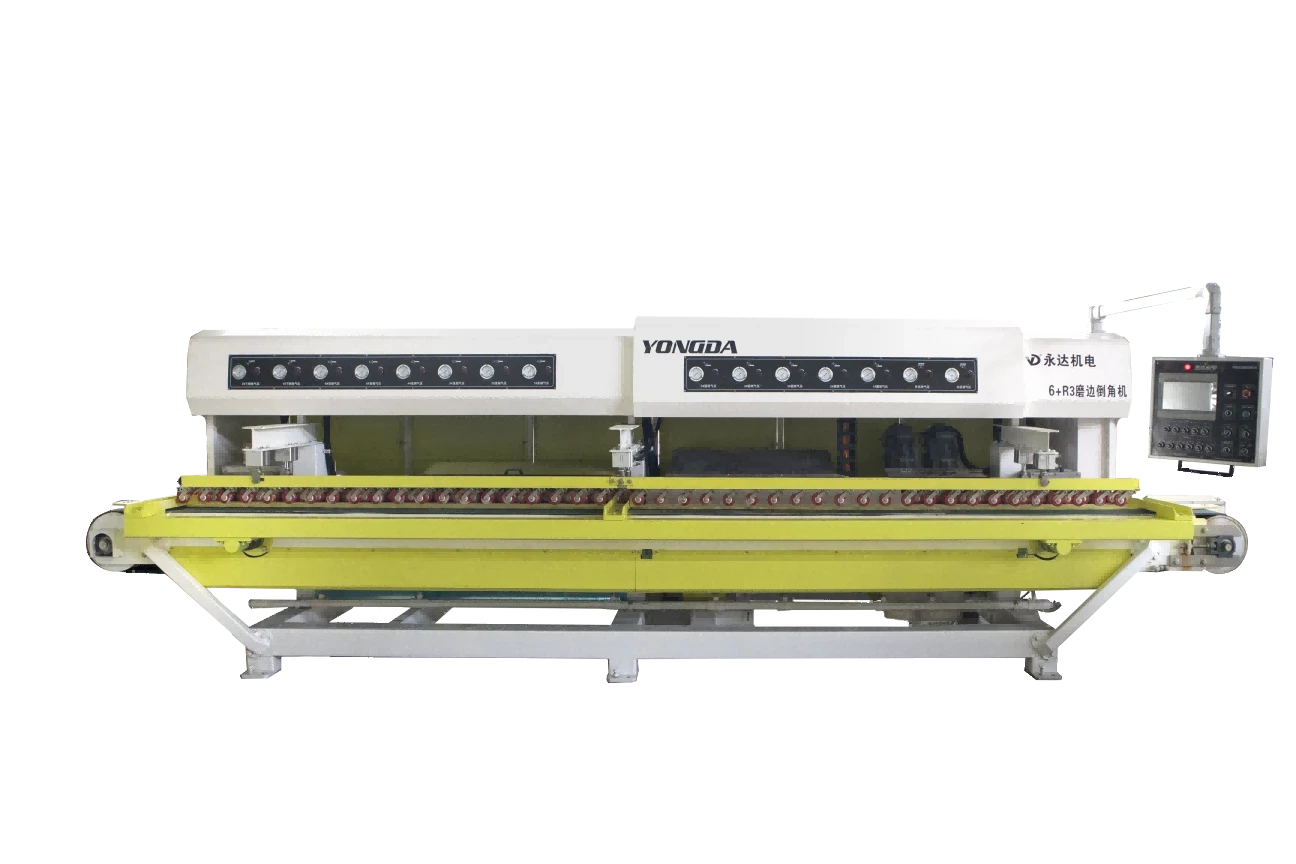

Stone slab cutting machines are the backbone of the stone industry, enabling fabricators to create stunning and durable products.

Choosing the right ceramic slab cutting machine is crucial for achieving precision and efficiency in your projects.

How to achieve precise cuts with ceramic slab cutting machines? Click to read to know more.

A ceramic slab cutting machine is an invaluable tool for achieving precise and high-quality cuts in ceramic materials.

With many options of stone CNC machining centers available, understanding the key features to consider can help you make an informed choice.

Stone machining centers have changed the stone machining industry, offering unparalleled precision, efficiency, and versatility.