Choosing the right ceramic slab cutting machine is crucial for achieving precision and efficiency in your projects. With a variety of machines available, understanding their features and how they align with your specific needs is essential. This guide will explore the different types of ceramic slab cutting machines, and their features, and provide tips on selecting the best one for your requirements.

Types of Ceramic Slab Cutting Machines

Ceramic slab cutting machines can be categorized based on their functionality and design. Here are the main types:

Manual Tile Cutters: Manual tile cutters are ideal for smaller projects or DIY enthusiasts. They typically consist of a scoring wheel and a lever to snap the tile along the scored line. These machines are lightweight, portable, and suitable for cutting ceramic tiles and thinner slabs. However, they may not provide the precision needed for larger or thicker materials.

Electric Tile Saws: Electric tile saws are more robust and designed for heavier tasks. They use a diamond blade to cut through tiles and slabs, making them suitable for harder materials like porcelain and granite. These machines often come with a water reservoir to cool the blade and reduce dust, enhancing both safety and precision. They are ideal for intricate cuts and thicker slabs, making them a popular choice among professionals.

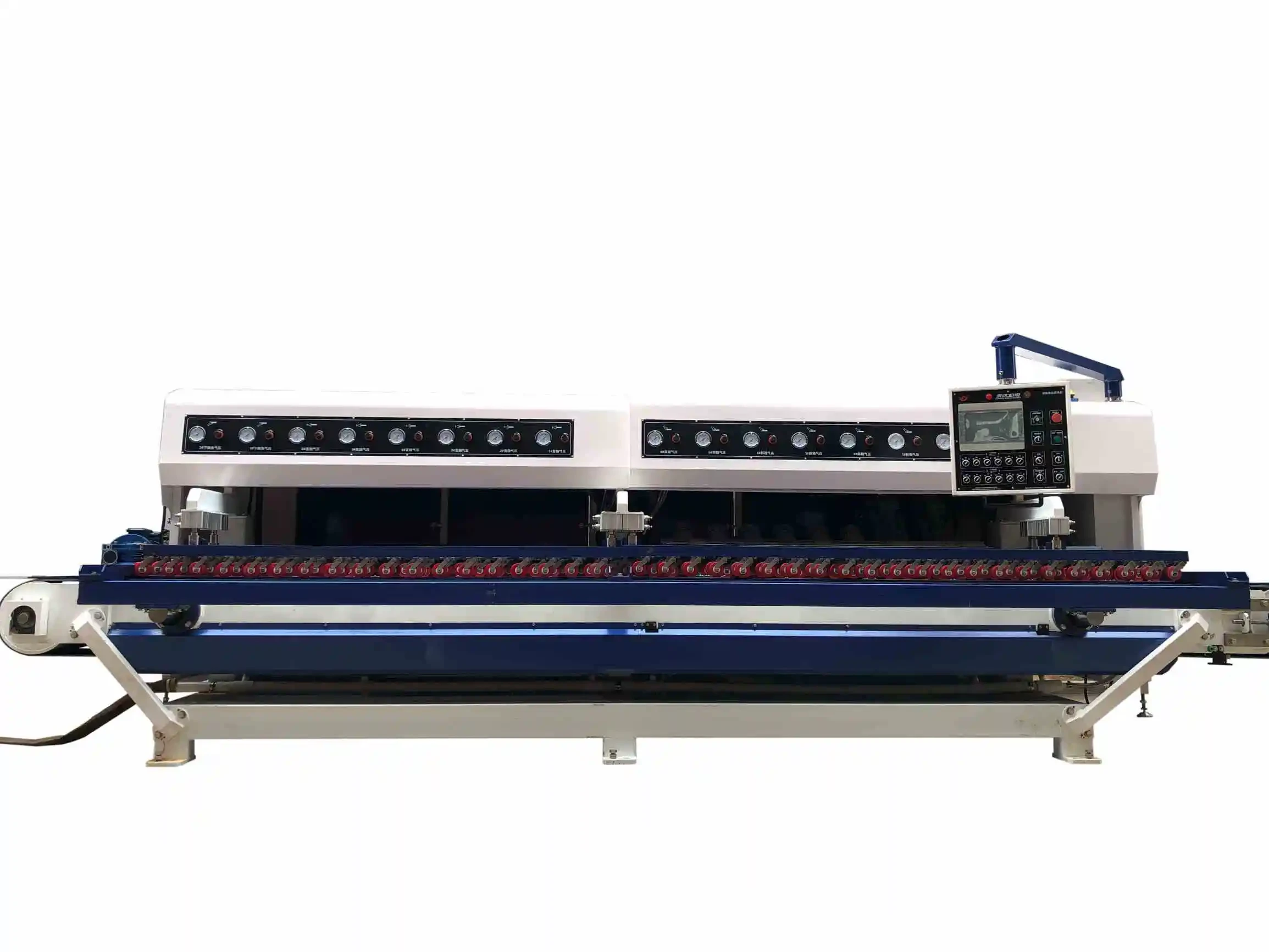

Bridge Saws: Bridge saws are heavy-duty machines designed for large-format tiles and slabs. They feature a stationary bridge that supports the saw blade, allowing for precise cuts on large pieces. These machines are suitable for both straight cuts and angled cuts, making them versatile for various applications. Some models include features like adjustable cutting angles and water cooling systems to prevent overheating.

CNC Machines: Computer Numerical Control (CNC) machines offer the highest level of precision and automation. They are capable of executing complex cutting patterns and are ideal for high-volume production. CNC machines can handle various materials and thicknesses, making them suitable for intricate designs and custom projects. However, they require a higher initial investment and technical expertise to operate.

Key Features to Consider

When selecting a ceramic slab cutting machine, several features should be evaluated to ensure it meets your specific needs:

Cutting Capacity: The maximum cutting length and thickness are critical factors. Ensure the machine can accommodate the sizes of slabs you plan to work with. For example, some machines can cut slabs up to 340 cm in length, while others may have a more limited capacity.

Blade Type and Size: The type of blade used can significantly impact cutting performance. Different materials require specific blade types, such as diamond blades for harder surfaces. Additionally, the diameter of the blade should correspond with the machine's power and intended use. Machines with adjustable blade sizes can offer greater versatility.

Cooling System: Cutting hard materials generates significant heat, which can damage both the blade and the material. Machines with integrated water cooling systems help maintain optimal cutting temperatures and reduce dust, improving the overall quality of the cut.

Portability and Weight: Consider the machine's weight and portability, especially if you need to transport it between job sites. Manual cutters are generally lightweight, while electric saws and bridge saws can be heavier and may require a dedicated workspace.

Ease of Use: Look for machines with user-friendly features, such as adjustable cutting angles, easy blade replacement, and intuitive controls. This is particularly important for those who may not have extensive experience with cutting machinery.

How to Choose the Right Machine?

Selecting the right ceramic slab cutting machine involves assessing your specific needs and project requirements. Here are some steps to guide your decision:

Assess Your Projects: Determine the types of materials and thicknesses you will be cutting. If you frequently work with large-format tiles, a bridge saw or CNC machine may be necessary.

Evaluate Your Budget: Consider how much you are willing to invest. Manual cutters are budget-friendly, while electric saws and CNC machines come at a higher cost but offer greater capabilities.

Consider Future Needs: Think about potential future projects. Investing in a more versatile machine may save you money in the long run if your project scope expands.

Test Before You Buy: If possible, test the machine to ensure it meets your expectations in terms of performance and ease of use.

Conclusion

Choosing the right ceramic slab cutting machine is essential for achieving high-quality results in your projects. By understanding the different types of machines available, their features, and how to match them with your specific needs, you can make an informed decision that enhances your cutting efficiency and precision.

Whether you opt for a manual cutter for smaller jobs or a robust bridge saw for larger projects, the right machine will significantly impact your workflow and the quality of your finished products. If you need such equipment, you can choose YONGDA, which has 19 years of experience in the design, manufacture, and sales of deep processing equipment for stone, ceramics, glass, metal, etc., to provide you with machine solutions that you can trust.