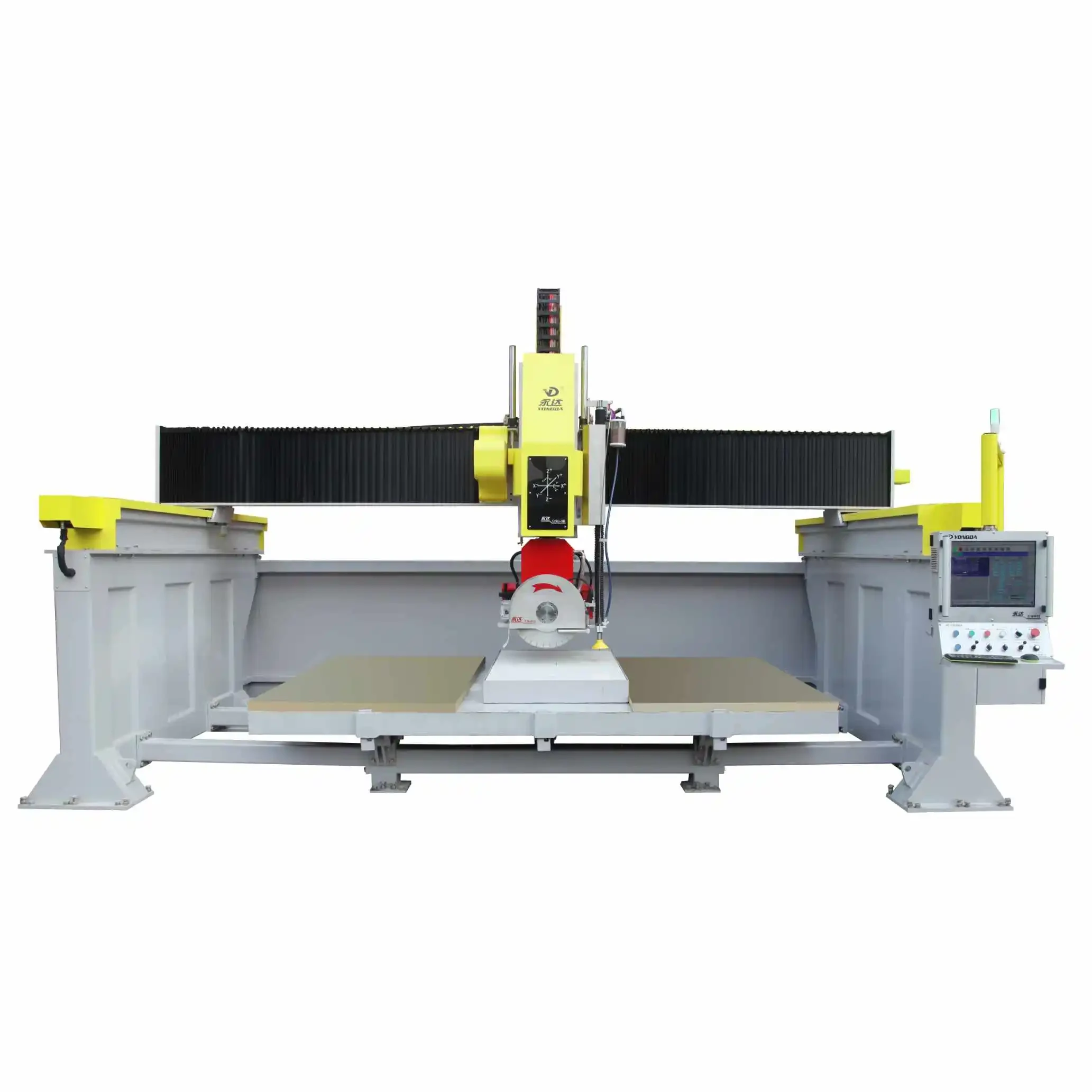

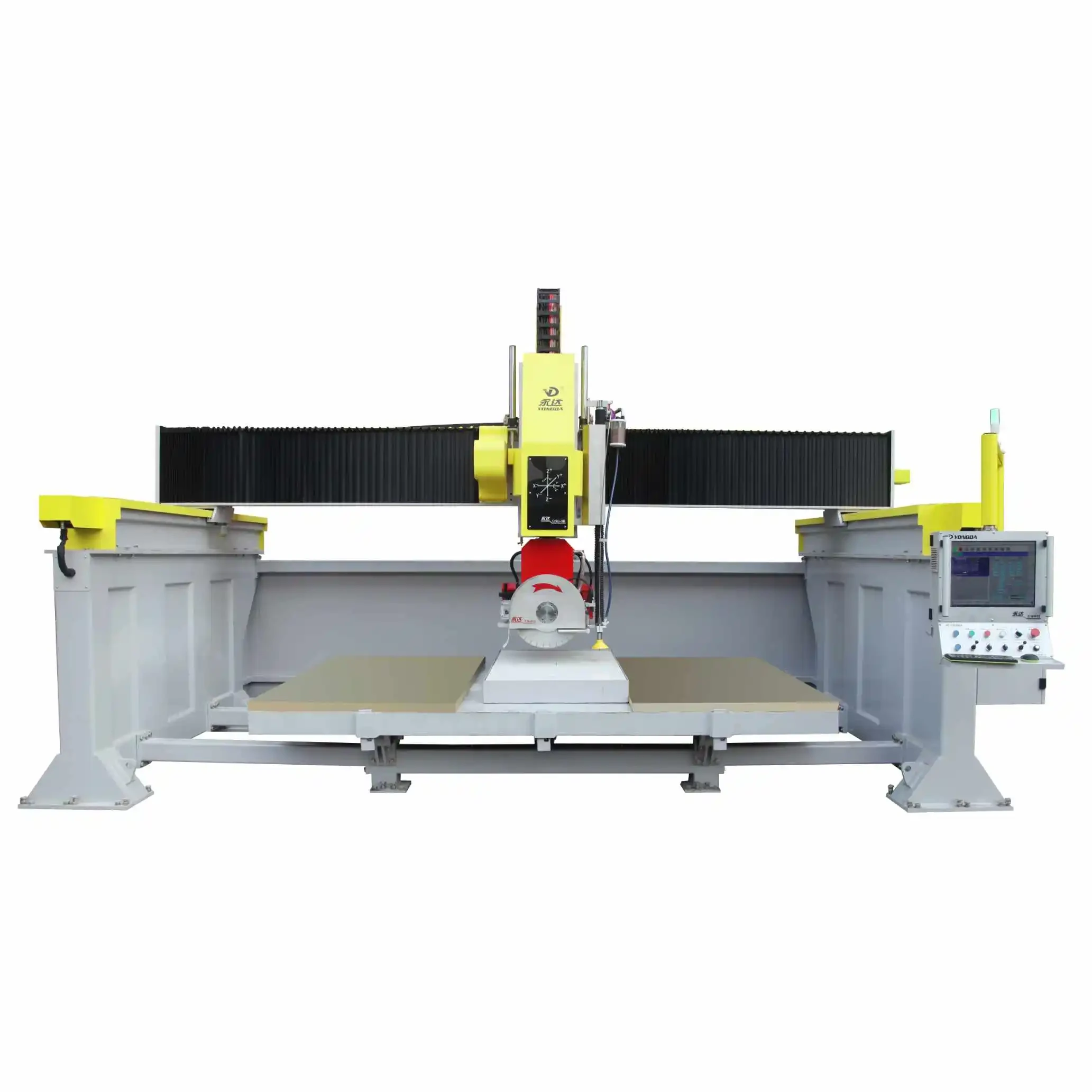

In the world of precision cutting, bridge cutters have become indispensable tools for industries such as construction, stone fabrication, and manufacturing. Their ability to handle heavy materials and deliver exceptional precision has made them worth the investment for businesses.

Why investing in a bridge cutter is a smart choice? You will understand this after reading this article.

Increased Productivity and Efficiency

Investing in a bridge cutter significantly boosts productivity and efficiency. These machines can handle large-scale cutting tasks, reducing the time and effort required to complete projects.

With their high cutting speeds and automation capabilities, bridge cutters enable businesses to meet tight deadlines and deliver projects on time, thereby enhancing customer satisfaction and fostering growth.

Precision and Accuracy

Bridge cutters are renowned for their exceptional precision and accuracy in cutting thick and heavy materials. Their sturdy structure and advanced cutting mechanisms allow for intricate cuts, beveling, and shaping with utmost precision.

4 axis CNC bridge cutter/5 axis CNC bridge cutter often incorporates computerized numerical control systems, which further enhance precision by automating cutting operations and minimizing human error.

Versatility in Material Handling

Bridge cutters are designed to handle a wide range of materials, including stones, granite, marble, and composites. This versatility enables businesses to cater to various customer demands and expand their service offerings.

The ability to cut through thick materials with ease makes bridge cutters ideal for tasks such as creating countertops, architectural elements, and intricate designs.

Enhanced Safety Features

Bridge cutters are equipped with advanced safety features to ensure operator protection. The features may include emergency stop buttons, safety interlocks, and protective enclosures, minimizing the risk of accidents and injuries.

Moreover, modern bridge cutters are designed to reduce operator fatigue by incorporating ergonomic features and intuitive controls, promoting a safer and more comfortable working environment.

Longevity and Durability

Bridge cutters are built to withstand heavy-duty cutting tasks, making them durable and long-lasting. The robust construction and high-quality components ensure that these machines can endure rigorous operations and maintain their performance over time.

Choosing reliable bridge cutting machine manufacturers and suppliers and conducting regular maintenance can further extend the lifespan of a bridge cutter, maximizing the return on investment.

Cost Savings in the Long Run

While the initial investment in a bridge cutter may seem significant, it offers substantial cost savings in the long run. By bringing cutting operations in-house, businesses eliminate the need to outsource such tasks, reducing outsourcing costs and lead times.

The precision and accuracy of bridge cutters minimize material waste, maximizing the utilization of expensive materials. This, in turn, reduces overall production costs and increases profitability.

Adaptability to Technological Advances

The cutting-edge nature of bridge cutters allows for easy integration with technological advancements. Many bridge cutters can be equipped with advanced software systems, enabling operators to create complex designs and execute intricate cutting patterns with ease.

Bridge saw with waterjet is suitable for the stone, countertops, and cabinetry industry.

1. Combined AC 5 axis water jet and 5 axis bridge saw function. Cutting, drilling, chamfering, carving, molding, engraving, and more functions combined in one machine.

2. Saw cutting, water jet drilling, and small-size curve cutting, no need to move the stone from one machine to another machine, increase working efficiency, save time and cost.

3. Save operator labor cost, only need one person to operate this combined machine.

4. Save space for the factory, compared to two different machines, combined machines save a lot of space.

5. Cheaper price, compared to the two machines, this price is really cheap.

6. Reduce possible problems. Compare to two machines, a combined machine is easier to do maintenance.

7. Good machine performance, imported servo motors, ball screws, and guide are used in this machine to keep it working fine.

Conclusion

Investing in a bridge cutter offers numerous benefits for businesses in the construction, stone fabrication, and manufacturing sectors. The unmatched precision, versatility, increased productivity, and cost savings make bridge cutters a wise investment choice.

Moreover, the enhanced safety features, durability, and adaptability to technological advances ensure that these machines provide long-term value to businesses. By harnessing the power of a bridge cutter, companies can elevate their cutting capabilities, deliver high-quality products, and gain a competitive edge in their respective industries.