Categorys

Hot Product

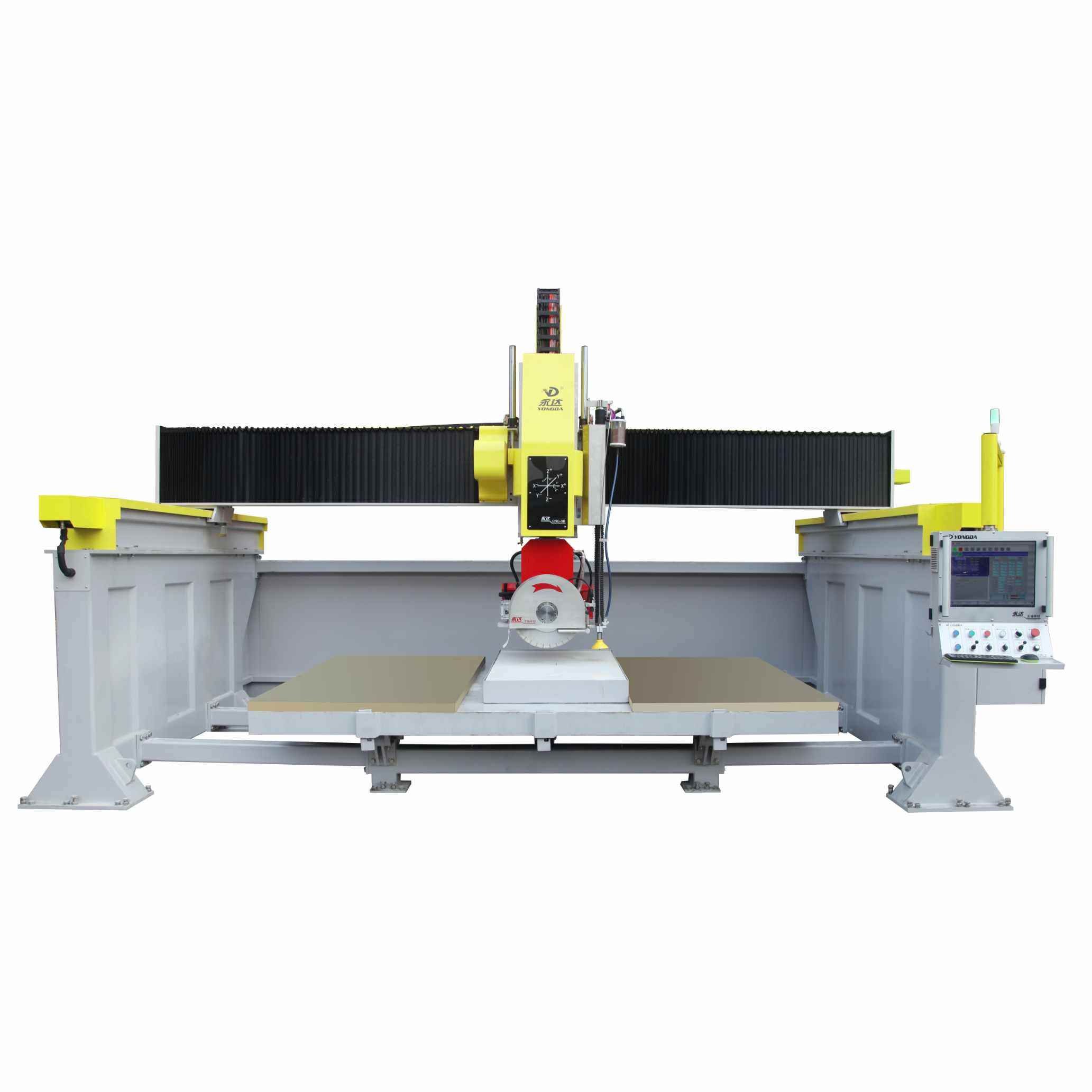

Bridge saw with waterjet

Bridge Saw with Waterjet Cutting can cut the corner. One machine cutting, save place save time.

Great system and CAD/CAM, easy operation.Slab cutting in one machine, avoiding the slab movement.

Bridge Saw with Waterjet

A bridge saw with waterjet, also known as a waterjet bridge saw or a waterjet cutting bridge saw is a powerful and versatile cutting machine used in various industries, particularly in stone fabrication and construction.

The waterjet bridge saw is typically controlled by computer numerical control systems, which enable precise programming and automation of the cutting process. Combining a waterjet system with a bridge saw creates a highly efficient cutting solution. The saw provides the stability and structure necessary for precise cutting, while the waterjet offers the ability to make intricate cuts and handle a variety of materials. The waterjet can be used alongside or in conjunction with the saw blade, allowing for increased versatility in cutting options.

Product Details

Bridge saw with waterjet is suitable for stone, countertops, cabinetry industry.

1. Combined AC 5 axis water jet and 5 axis bridge saw function. Cutting, drilling, chamfering, carving, molding, engraving, more functions combined in one machine.

2. Saw cutting, water jet drilling and small size curve cutting, no need move stone from one machine to another machine, increase working efficiency, save time and cost.

3. Save operator labour cost, only need one people to operate this combined machine.

4. Save space for factory, compare to two different machine, combined machine save a lot of space.

5. Cheaper price, compared to two machines, this price is really cheap.

6. Reduce possible problem. Compare to two machines, combined machine is easier to do maintenance.

7. Good machine performance, imported servo motors, ball screw and guide are using in this machine to keep it working fine.

8. All hard materials can process such as steel, glass, ceramic, stone, sintered stone, plastic etc.

This Bridge Saw with Waterjet can used for stone, ceramic, sintered stone processing. For kitchen top processing, table processing, island processing, and most counter top processing.

Bridge Saw with Waterjet Can Process a Variety of Materials

The bridge saw with waterjet technology is highly versatile and suitable for processing various materials such as stone, ceramic, and sintered stone.

Stone materials including granite, marble, quartzite, and others can be efficiently cut and shaped using this technology due to its precision and ability to handle diverse textures and hardness levels.

Ceramic and sintered stones, known for their durability and resistance to scratches and stains, can also be effectively processed using this method, providing a precise finish.

Bridge Saw with Waterjet in Different Processing

Kitchen Top Processing

One of the primary applications of the bridge saw with waterjet is in the creation of kitchen countertops. The technology ensures accurate cutting and shaping of stone or ceramic slabs to fit specific kitchen designs and dimensions. It allows for the creation of smooth edges, precise cutouts for sinks, and customization according to customer preferences.

Table Processing

Whether it's dining tables, coffee tables, or other types of tables, the bridge saw with waterjet enables the shaping and cutting of stone or ceramic slabs for tabletops.

This technology ensures the fabrication of sturdy and aesthetically appealing table surfaces that can withstand wear and tear while enhancing the overall look of the furniture.

Island Processing

Islands in kitchens or other areas often require customized surfaces. The bridge saw with waterjet facilitates the accurate shaping and cutting of materials to fit island designs. The precision cutting allows for seamless integration of the countertop material, providing a cohesive and visually appealing island structure.

Countertop Processing

Beyond kitchen tops and islands, this technology caters to various countertop processing needs in both residential and commercial settings. It enables the creation of countertops for bathrooms, bars, reception desks, and other spaces where durable and aesthetically pleasing surfaces are required.

Precision and Efficiency

The bridge saw with waterjet combines the accuracy of waterjet cutting technology with the power of a bridge saw, ensuring high precision and efficiency in material processing. Its ability to handle intricate designs, curved edges, and precise cuts minimizes material wastage and enhances the overall quality of finished products.

In summary, the bridge saw with waterjet technology serves as a versatile and efficient tool for shaping and cutting stone, ceramic, and sintered stone materials. Its applications span various aspects of interior design and construction, from kitchen and table processing to countertop fabrication, offering precision and customization in creating durable and visually appealing surfaces.