Bridge cutting machines, also known as bridge saws or stone-cutting machines, are powerful tools used in various industries for cutting and shaping different materials, primarily stone, and other hard surfaces.

What Are the Applications of Bridge Cutting Machines?

5 axis bridge cutting machines or 4 axis bridge cutting machines can be used in many industries such as stone processing, tile production, and more. Here are some of the applications details of bridge cutting machines:

Stone Processing

Bridge cutters are extensively used in the stone processing industry for cutting and processing natural stones such as granite, marble, limestone, and quartz. They are used to create precise cuts, slabs, countertops, tiles, and other stone products.

Construction Industry

In the construction sector, bridge cutting machines are used for cutting and shaping stone and concrete materials for architectural elements, including pillars, columns, balusters, and decorative pieces. CNC bridge saws help achieve accurate dimensions and intricate designs.

Monument and Memorial Manufacturing

Bridge cutting machines play a crucial role in the creation of monuments and memorials. They enable the precise cutting and shaping of stone materials, allowing for intricate engravings, lettering, and custom designs.

Kitchen and Bathroom Countertop Fabrication

Bridge cutting machines are widely used in the fabrication of kitchen and bathroom countertops. They allow for precise cutting, shaping, and edging of stone slabs to fit specific dimensions and designs.

Tile Production

Bridge cutting machines are used in the production of tiles for various applications. They can cut large stone slabs into smaller tile sizes with accurate dimensions.

Architectural and Interior Design

Bridge cutting machines ensure precision and consistency in cutting stone materials. In architectural and interior design projects, bridge cutting machines are employed to create custom stone elements, including wall cladding, flooring, staircases, and fireplace surrounds.

Industrial Manufacturing

Bridge cutting machines are utilized in industrial manufacturing processes for cutting and shaping hard materials like metals and composites. They find applications in sectors such as automotive, aerospace, and machinery manufacturing.

Art and Sculpture

Artists and sculptors use bridge cutting machines to bring their creative visions to life. These machines enable the precise cutting, shaping, and carving of stone, allowing artists to express their creativity in sculpture and art installations.

Restoration and Renovation Projects

Bridge cutting machines are useful in restoration and renovation projects involving historic buildings and monuments. They help replicate intricate details, replace damaged stone elements, and ensure consistency with the original design.

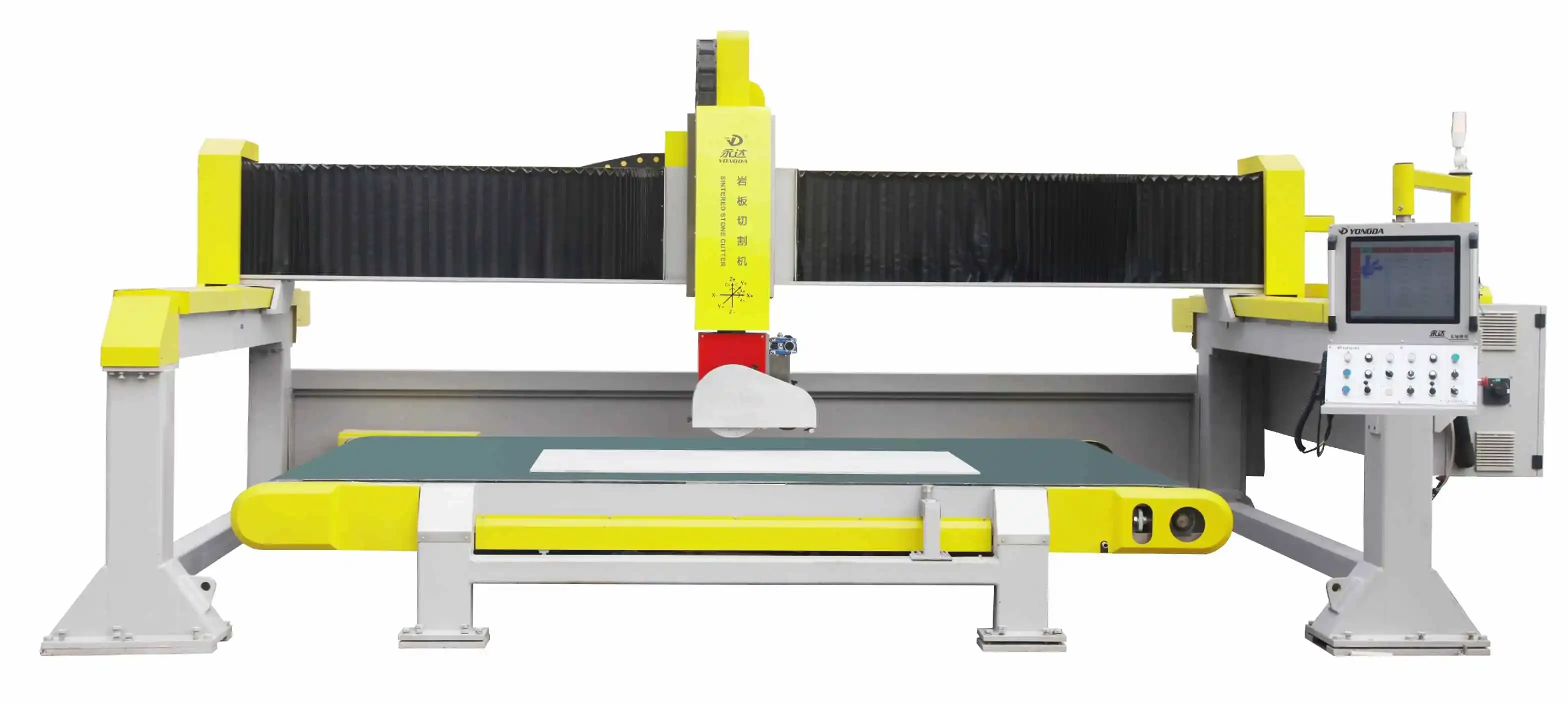

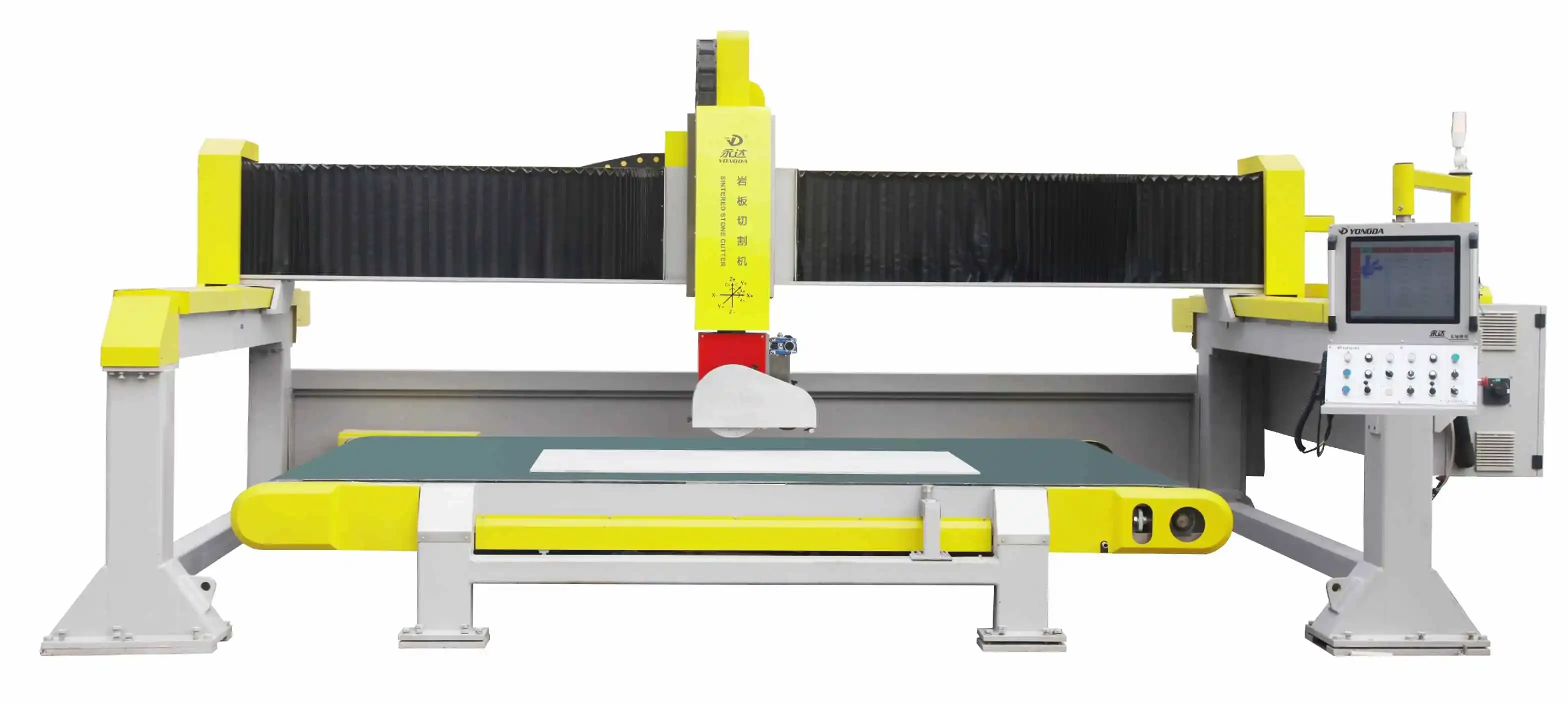

bridge cutting machine for sale

After understanding the many applications of bridge cutting machines, you may also be interested in the following frequently asked questions.

What Types of Materials Can Bridge Cutting Machines Cut?

Bridge cutting machines are primarily designed to cut hard materials such as natural stones (granite, marble, limestone, etc.), engineered stones, concrete, ceramics, and certain metals.

Can Bridge Cutting Machines Make Curved Cuts?

Most bridge cutting machines are primarily designed for straight cuts, but there are advanced models available that incorporate CNC technology, allowing for more complex bridge saw edge mitering, including curves and intricate shapes.

How Accurate Are the Cuts Made by Bridge Cutting Machines?

Bridge cutting machines are known for their high precision and accuracy. When operated properly and with the appropriate settings, they can produce cuts with tight tolerances, ensuring precise dimensions and clean edges.

Are Bridge Cutting Machines Easy to Operate?

5 axis bridge cutting machine or 4 axis bridge cutting machine requires some level of training and expertise to operate effectively. Familiarity with the machine's controls, understanding of the cutting process, and knowledge of safety protocols are essential. However, with proper training, operators can become proficient in using the machine.

Can Bridge Cutting Machines Be Automated?

Yes, some bridge cutting machines are equipped with automation features, such as CNC systems. These systems allow for automated cutting processes, including pre-programmed cuts, complex shapes, and even integration with CAD/CAM software for precise design replication

Overall, bridge cutting machines are versatile tools used in various industries where precise cutting, shaping, and processing of hard materials like stone are required.

The right bridge cutting machine can improve your production line, boost sales, and contribute to business success. As one of the professional bridge cutting machine manufacturers, you are welcome to learn more at Yongda, and we are pleased to provide you with related products and services.