Categorys

Hot Product

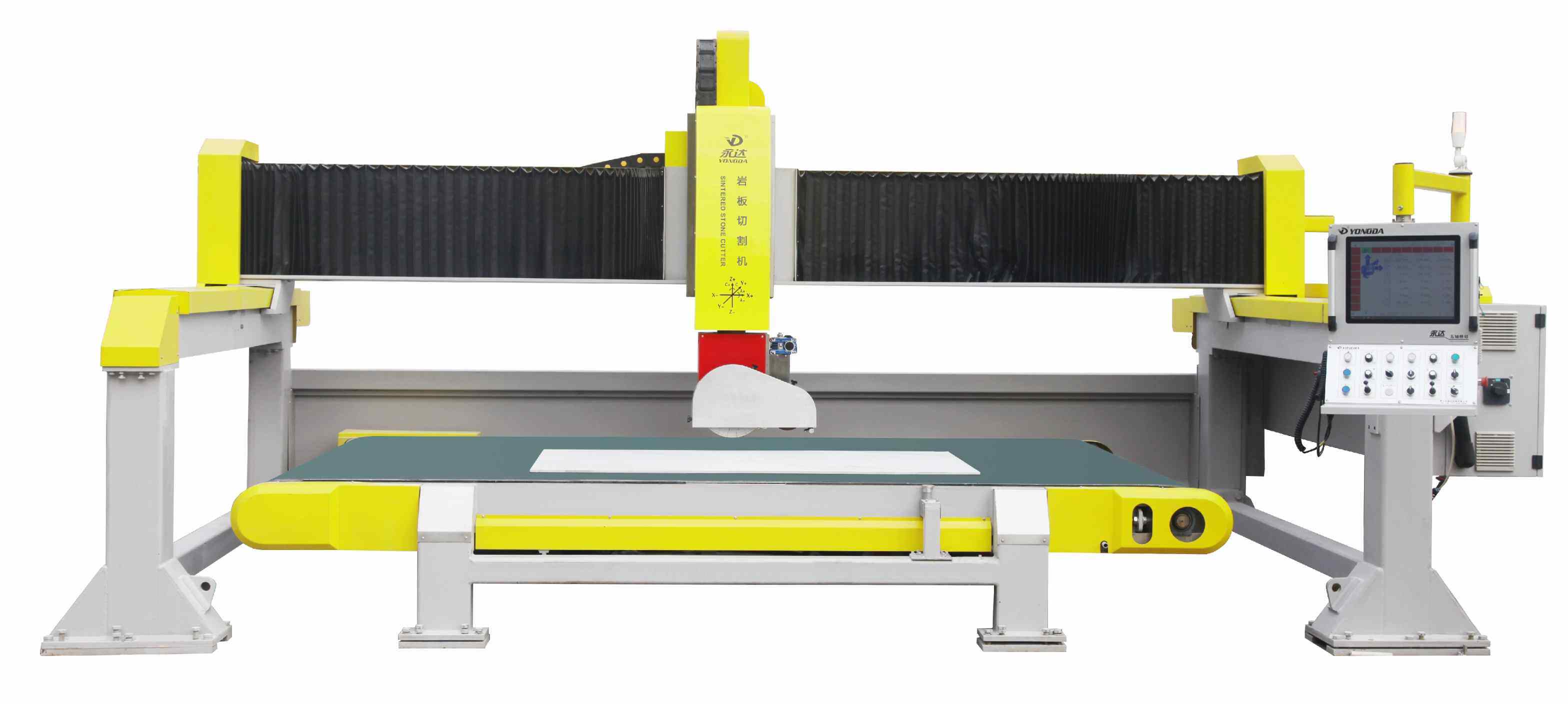

Sintered Stone Cutting Machine (Double disc, 4 axis)

Front and behind disc cutting, it doesn’t t hurt the sintered stone’s surface, no chipping. Significantly reduces the rate of cutting breakage.

4 Axis Sintered Stone Cutting Machine

Sintered stone is a type of engineered stone made by compacting and sintering natural minerals and pigments together under high heat and pressure. A 4-axis sintered stone cutting machine is a specialized piece of equipment used for cutting and shaping sintered stone materials.

The 4-axis sintered stone-cutting machine typically operates using computer numerical control (CNC) technology. 4 axis bridge cutter enables it to perform various cutting techniques, including straight cuts, bridge saw inclined cutting, curved cuts, and intricate designs.

Advantages of Using Sintered Stone Cutting Machine

1.Industrial leading programming software,

visualized, fast, easy to learn.

2.Operating system simple and easy,use

International leading brand servo control, ball screw and guide,

fast, stable and reliable.

3.Front and behind disc cutting, it doesn’t t hurt

Stone, sintered stone and ceramic’s surface, no chipping.

4.Stable sintered stone loading, cutting function separately, convenient and efficient.

5.19”screen, button and rocker integrated

panel, fast and easier operating.

|

MODEL |

UNIT |

YD-3220 |

|

|

Processing size |

mm |

3200×2000 |

|

|

Processing thickness |

mm |

≤20 |

|

|

Z Axis stroke |

mm |

250 |

|

|

C Axis stroke

|

° |

±185° |

|

|

Notching lift and down stroke |

mm

|

50 |

|

|

Table size |

mm |

3600×2200 |

|

|

Table tilting degree |

° |

0-85° |

|

|

Diameter of the cutting disc |

mm |

φ300×φ50 |

|

|

Diameter of the notching disc |

mm |

φ150×φ30 |

φ180×φ30 |

|

Control method |

|

Servo control |

|

|

Operating system |

|

Taiwan system |

|

|

Power supply |

V/Hz |

AC 380V / 50Hz |

|

|

Total power |

kw |

27 |

31 |

|

Water consumption |

L/min |

40 L/min |

|

|

Outer dimension |

mm |

6000(L)×3900(W)×3100(H) |

|

|

Total weight |

Kg |

5000 |

|

Using a 4-axis sintered stone-cutting machine offers several advantages. It allows for efficient and precise cutting of sintered stone, reducing material waste and increasing productivity. YD double disc & 4 axis sintered stone cutting machine is used for sintered stone cutting, quartz stone, marble, artificial stone, glass, and so on.

The versatility of 4 axis bridge cutting machine for sintered stone enables the creation of complex shapes and designs, making it suitable for a wide range of applications, including kitchen countertops, bathroom vanities, flooring, and architectural elements.

Applications in Kitchen Countertops

The machine's precision cutting capabilities make it ideal for crafting bespoke kitchen countertops.

Sintered stone, known for its durability and resistance, becomes a perfect material for kitchen surfaces when shaped with precision using the 4 axis cutting machine.

Utilization in Bathroom Vanities

The machine's adaptability extends to the creation of bathroom vanities with intricate detailing.

Sintered stone's resistance to moisture and heat, coupled with the precision of the cutting machine, results in durable and aesthetically pleasing bathroom surfaces.

Flooring Solutions with Sintered Stone

Flooring demands both durability and visual appeal, and the 4 axis bridge cutting machine caters to these requirements.

It allows for the creation of unique floor patterns and designs using sintered stone, ensuring a long-lasting and stylish flooring solution.

Architectural Elements and Custom Designs

Beyond conventional applications, the machine finds its place in crafting architectural elements.

Custom designs for wall cladding, pillars, and other architectural details become achievable, enhancing the overall aesthetic of interior and exterior spaces.