Waterjet cutting proves to be one of the most versatile and safe cutting processes on the market. Its ability to cut thicker and a wider range of materials whilst still being able to create a safe environment to do so is why the waterjet cutter has become the popular cutting method in a variety of industries.

Waterjet machining is one of the fastest-developing machining processes because of the versatility and benefits it can provide to a wide range of industries. Learn about the range of waterjet applications that waterjet cutting machines can provide to your industry, business, or production line.

What Is Waterjet Cutting Machine?

AC 5 Axis Waterjet Cutting Machine

A waterjet cutting machine is a cutting machine that uses high-pressure water jets for cold cutting.

Water jet cutting is a machining process that uses high-pressure jets of water to cut and shape various types of materials. A waterjet cutter can be used to cut, shape, and design a workpiece to meet exact specifications.

Two Types Of Waterjet Cutting Machining

The water for cutting can be pure or mixed with abrasives for even greater cutting power. There are two primary types of industrial waterjet cutting, pure waterjets, and abrasive waterjets.

Pure water jet cutting, which uses water as its medium, is specifically designed for slicing through soft materials. However, when an abrasive is introduced into the water stream, the cutting process becomes significantly more aggressive, enabling the machine to cut through even hard metals.

Pure Water Cutting Machine

This type of waterjet cutting uses only the pressure and, consequently, the speed of pure water to cut through things. Pure waterjet cutting is typically restricted to thin materials, like food, foil, cardboard, rubber, rubber, and wood. Unlike CNC cutting and laser cutting, it is a cold-cutting method and would not generate heat.

Abrasive Water Cutting Machine

Abrasive waterjets operate by combining ultra-high pressure water with abrasive particles such as garnets. This fusion of pure water and abrasive substances results in a remarkably powerful stream, thereby broadening the range of materials it can cut through, especially harder ones.

The cutting technology used here is non-thermal and would not generate heat. Abrasive waterjet cutting is suitable for ceramics, rocks, and metals. 5 axis waterjet cutting machines and 3 axis waterjet cutting machines are often easily found in the stone processing industry.

3 Axis Waterjet Cutting Machine

The Proper Waterjet Cutter Will Optimize Your Line

The type of industrial waterjet cutting machine you choose should depend on the type of material you want to cut.

Pure waterjet cutting will be favored in the food and pharmaceutical industries. Pure waterjet cutting is better when you need higher cutting accuracy, especially for materials with complex geometry.

For harder and thicker materials, abrasive water jets will do the best job. Many waterjet cutters today have an abrasive mixing chamber that you can attach to the nozzle of the waterjet cutter.

Waterjet Cutting Machine Manufacturers & Suppliers

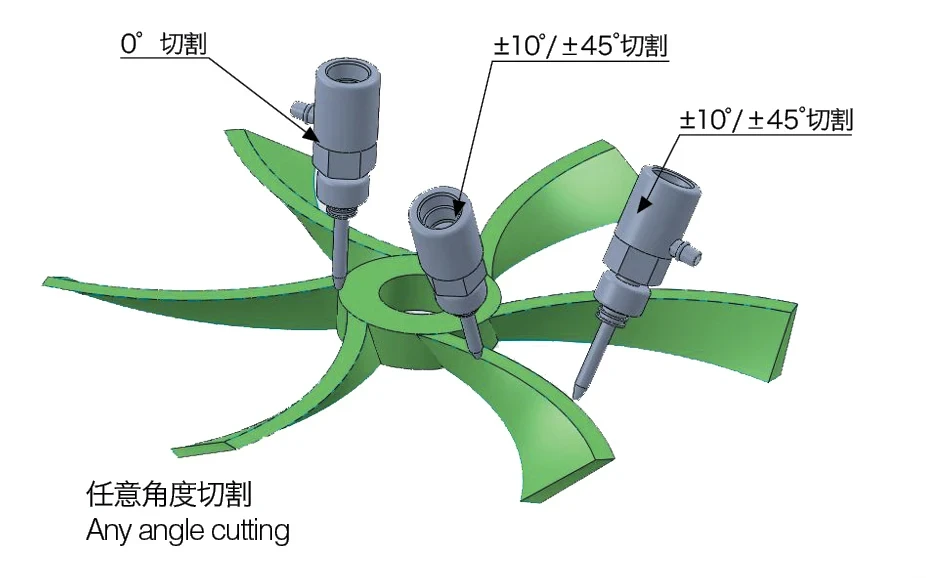

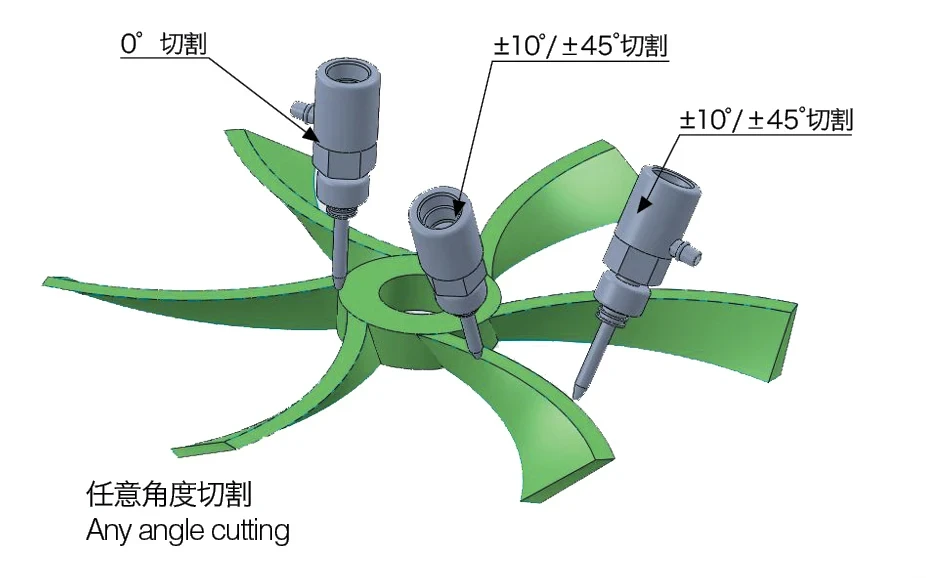

Waterjet cutting machines can easily achieve arc plate cutting, cylinder cutting, and spiral leaf cutting ... making the impossible possible. A water jet cutting head can cut an arbitrary curve and arbitrary angle, curve, and angle changes are controlled by a computer which makes it more stable.

Waterjet Cutting Machine for Sale

Why Choose Yongda Waterjet?

Choosing Yongda Waterjet guarantees you not only a high-end brand of waterjet in China but also a solution that has been matured and refined over 15 years of manufacturing experience. Our waterjets are designed to meet the high accuracy requirements of water cutting, capable of both plane cutting and 3D cutting, ensuring your design requirements are met in one-time processing. With parts processed by advanced imported equipment, our waterjets offer stability, reliability, and satisfaction that is unparalleled. Trust Yongda Waterjet for all your water-cutting needs.

Ready to experience the unparalleled precision and power of Yongda Waterjet? Visit our website or contact us today for more information or to request a demo. Discover how Yongda Waterjet can change your production line.