Bridge cutting machines are indispensable tools in the realm of stone processing and fabrication. These advanced machines offer precision, efficiency, and versatility, allowing for the cutting and shaping of various materials.

Here are some types of materials that bridge cutting machines can effectively cut:

Natural Stone

One of the primary materials that bridge cutting machines excel at cutting is natural stone. From timeless classics like granite and marble to the rustic beauty of limestone and travertine, these machines are well-suited for shaping and transforming natural stone slabs. The ability to cut precise dimensions, curves, and angles makes bridge cutting machines invaluable for producing stunning countertops, flooring, wall claddings, and architectural elements using natural stone.

Engineered Stone

In recent years, the popularity of engineered stone has skyrocketed. Composed of quartz particles mixed with resins and pigments, engineered stone offers durability, consistency, and a wide range of colors and patterns. Bridge cutter equipped with the necessary tools and techniques can seamlessly cut engineered stone slabs, enabling the creation of custom countertops, vanities, and other interior surfaces.

Ceramic and Porcelain

Bridge cutting machines are not limited to cutting natural and engineered stone alone. These machines also excel at cutting ceramic and porcelain materials commonly used in the production of tiles. Whether it's large-format floor tiles, intricate mosaic patterns, or precisely shaped countertop tiles, bridge cutting machines ensure clean and accurate cuts, facilitating seamless installations and stunning designs.

Glass

Bridge cutting machines can extend their capabilities beyond stone and ceramic materials to cut glass. With the right tools and techniques, these machines can create precise cuts on glass surfaces. This versatility proves invaluable when crafting glass countertops, backsplashes, decorative glass elements, and other innovative applications that require precise shaping and sizing.

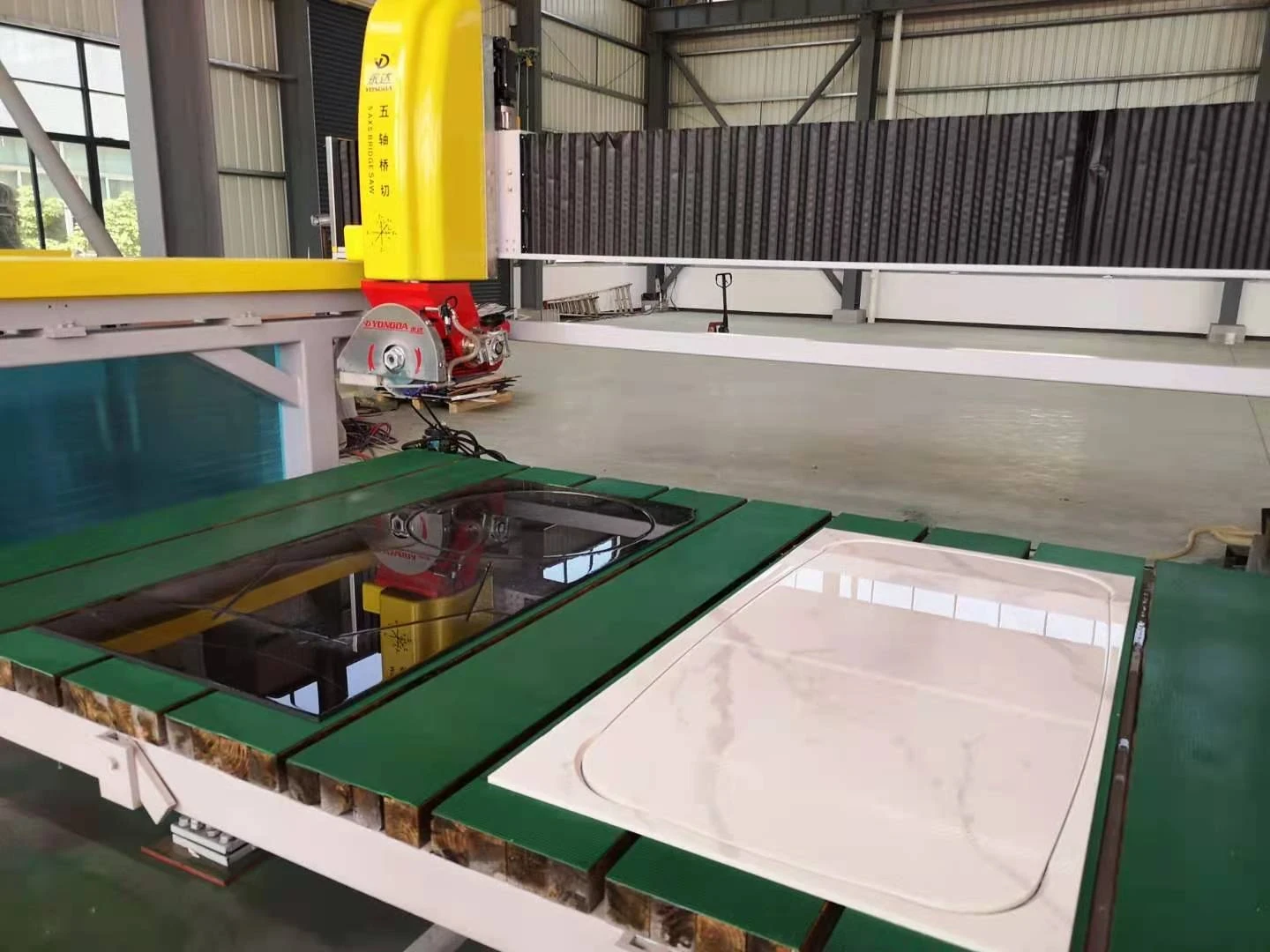

YD-3200 4 AXIS S/D - Bridge Cutting Machine for Sale

YD series 4 Axis Bridge Saw Machine is an intelligent cutting machine designed to meet the diversified needs of the processing for stone enterprises.

YD Bridge saw is a necessary processing equipment for the stone processing enterprises. The machine is multifunctional, easy to operate, and processed precisely but with low energy consumption. Requirements and different functions can be converted very fast and conveniently. Almost all the work can meet by one machine.

Product Details

1 Easy to learn, easy to control, and operate

2. Straight line, circular arc, grid, click to cut

3. Notching, chamfering, beveling, cutting as you like

4. Available in a variety of shapes like cambered shapes, engraving, drilling, profiling, etc

5. Can connect with a scanner, nesting as required, save materials save time

6. Easy to use, convenient and intelligent, high efficiency and low energy consumption

7. Apply international brand CNC control system, servo motor & driver

8. Can be seamlessly integrated with a scanner, realizing real-time scanning layout setting

9. With the internet remote diagnosis function, the system parameters can be modified by remote control

Conclusion

Bridge cutting machines are the epitome of versatility in the world of material cutting and shaping. From natural stone to engineered stone, ceramic and porcelain, and even glass, these machines showcase their adaptability in various industries, such as construction, interior design, and artistic endeavors.

With their ability to achieve accurate cuts, intricate designs, and flawless finishes, bridge cutting machines continue to revolutionize the way we process and transform a wide array of materials, allowing for breathtaking creations and exceptional craftsmanship.