Waterjet cutting machines are versatile and efficient tools utilized across various industries for precise cutting and shaping of materials. Waterjet cutting machines employ a high-pressure stream of water mixed with an abrasive substance to cut through different materials including metal, plastic, ceramics, and composites. This is why they are commonly associated with glass waterjet cutting and porcelain cutting waterjet.

A common query about waterjet cutting machines concerns the size and type of material they can handle. This article aims to provide comprehensive information on this topic and more about waterjet cutting machines.

Understanding the Waterjet Cutting Machine

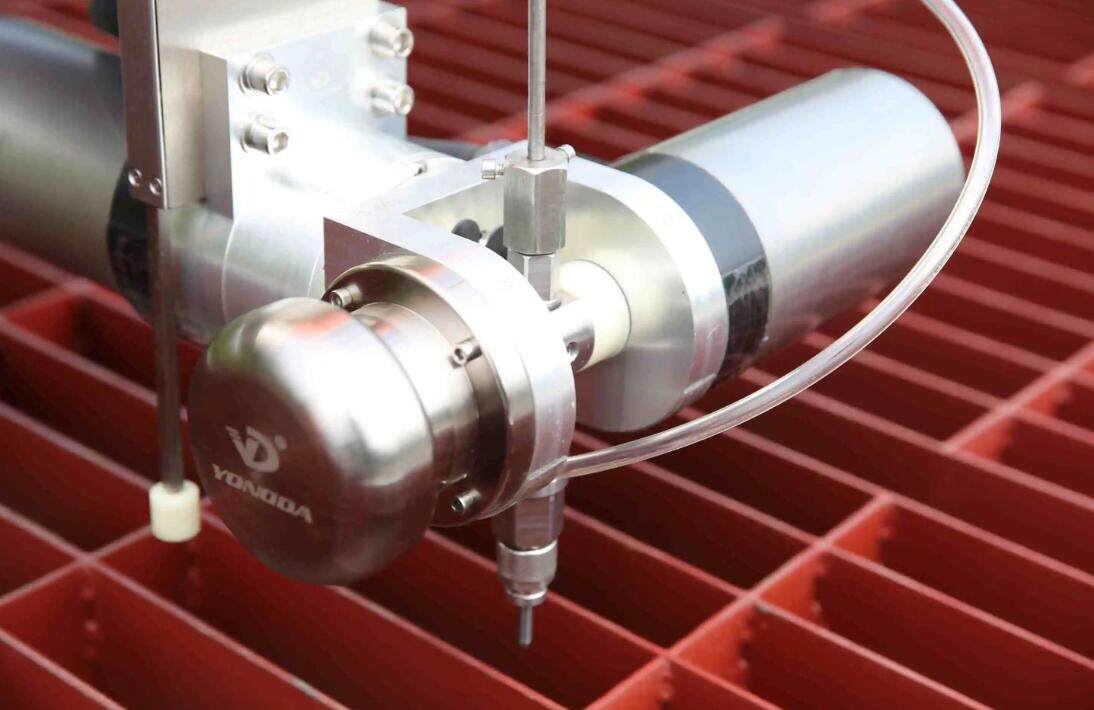

Before we delve into the specifics of material size and type, it's essential to understand what a waterjet cutting machine is. It's a cutting tool that uses a high-pressure stream of water mixed with an abrasive substance to cut through various materials. These machines can be controlled using computer numerical control (CNC) technology, offering precise and accurate cutting.

CNC water jet cutting machine for sale

How Does a Waterjet Cutting Machine Work?

A waterjet cutting machine operates by directing a high-pressure stream of water mixed with an abrasive substance to cut through materials. The operation of the machine is governed using CNC technology, ensuring precise and accurate cutting.

Material Size and Type: What Can a Waterjet Cutting Machine Handle?

Waterjet cutting machines can manage a wide range of materials and thicknesses, making them a versatile option for cutting various materials. The size and type of material a waterjet cutting machine can handle depend on the specific machine's capabilities and design.

Most CNC water jet cutting machines can handle materials up to 6 inches (15 centimeters) thick. However, some machines with specialized cutting heads or higher horsepower pumps can cut materials up to 12 inches (30 centimeters) thick or more.

The maximum size of the material that a waterjet cutting machine can handle also depends on the machine's cutting bed size. Besides thickness, the type of material being cut is also a crucial factor in determining the maximum size that a waterjet cutting machine can handle.

In essence, the size and type of material that a waterjet cutting machine can handle vary depending on the machine's specific capabilities and the material being cut.

Comparison: 5 Axis CNC Waterjet vs 3 Axis CNC Waterjet

Waterjet cutting machines come in two primary types: 3 axis CNC waterjet and 5 axis CNC waterjet.

3 axis CNC waterjet machines have a fixed cutting head that moves in three directions: up and down, left and right, and forward and backward. They are suitable for cutting simpler shapes and parts.

5 axis CNC waterjet machines, conversely, have a cutting head that can tilt and rotate, allowing for more precise and intricate cuts. These machines are ideal for cutting complex shapes and parts.

Can a Waterjet Cutting Machine Cut Through Metal?

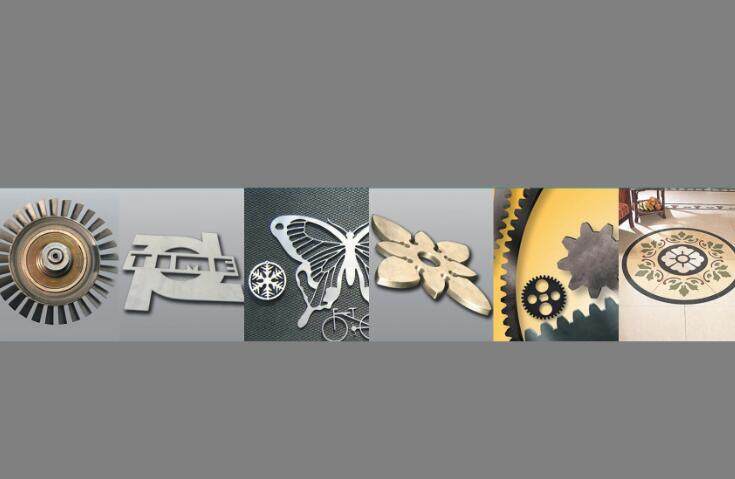

Yes, a waterjet cutting machine can efficiently cut through metal, including steel, aluminum, and titanium. Materials like plastics, ceramics, composites, and even certain types of stone can also be cut with waterjet technology.

Choosing the Right Waterjet Cutting Machine Manufacturer and Supplier

When selecting a waterjet cutting machine, it's important to choose a reputable supplier or manufacturer. A reliable supplier or manufacturer should offer a wide range of machines, provide excellent customer support, and offer warranties and after-sales services.

Waterjet Cutting Machine for Sale

If you're in the market for a waterjet cutting machine, options are available online or from local waterjet cutting machine suppliers.

When choosing a waterjet cutting machine, consider factors such as the machine's power, cutting speed, and accuracy. You should also consider the type of material you will be cutting and the machine's maximum cutting thickness. Additionally, opt for a machine that is user-friendly and comes with excellent customer support.

Conclusion

Waterjet cutting machines are versatile and efficient cutting tools that can handle a wide range of materials. They come in different types and sizes, and the maximum thickness of material they can cut depends on the machine's power and the type of material being cut.

When looking for a waterjet cutting machine, it's crucial to choose reputable waterjet cutting machine suppliers and consider factors like cutting speed, accuracy, maintenance, and environmental impact. Yongda is one of the waterjet cutting machine manufacturers in China. Contact us to explore how our Yongda waterjet can be seamlessly integrated into your stone processing plans.