The stone fabrication industry is evolving rapidly, thanks to the advent of advanced machinery like the stone slab cut-to-size machine. These machines are instrumental in cutting and shaping stone slabs to precise dimensions, catering to various applications such as countertops, flooring, walls, and decorative pieces.

Stone Slab Cut-to-Size Machine

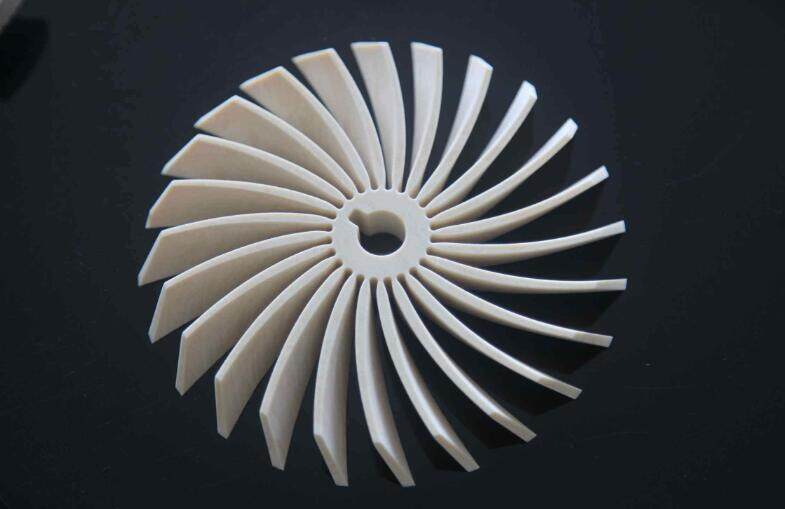

A stone slab cut-to-size machine is a specialized piece of equipment designed to process large stone slabs, such as granite, marble, quartz, and other natural or engineered stones. Based on project requirements, the machine utilizes advanced cutting tools—typically diamond blades or water jets—to slice slabs into specific dimensions.

These machines are widely used in construction, interior design, and architectural projects where precision and uniformity are paramount.

Key Features of Cut-to-Size Machines

Precision Cutting: Equipped with high-accuracy cutting tools, these machines can cut stone slabs within millimeters of desired dimensions. Advanced models may also include CNC (Computer Numerical Control) systems for automated and highly detailed cutting patterns.

Versatility: Many machines can handle a wide variety of stone materials, from soft marbles to hard granites, ensuring adaptability for different project needs.

High Efficiency: Modern machines are designed to maximize output by cutting multiple slabs or performing intricate cuts in a single cycle. This efficiency significantly reduces material waste.

Customization Options: Operators can program machines for straight cuts, curves, and beveled edges, making them ideal for intricate design work in interior spaces or bespoke architectural features.

Durability and Maintenance: Built with robust materials like stainless steel and heavy-duty components, these machines are designed to withstand harsh operating environments while ensuring minimal downtime.

Benefits of Using a Stone Slab Cut-to-Size Machine

Cost-Effective: Automating the cutting process reduces labor costs and minimizes waste, making it a cost-efficient option for businesses.

Improved Quality: Machines ensure consistent results, eliminating human errors common in manual cutting.

Time-Saving: High-speed cutting and automation capabilities drastically reduce production times.

Enhanced Safety: Modern machines come with advanced safety features, reducing the risk of accidents during operation.

Applications Across Industries

The demand for precision-cut stone slabs has seen an uptick in various industries, driving the popularity of these machines:

Construction: Used in creating flooring, wall claddings, and pavers.

Interior Design: Popular for countertops, tabletops, and custom furniture elements.

Memorials and Monuments: Essential for crafting detailed engravings and custom shapes in gravestones and memorial pieces.

Yongda AC 5 Axis Waterjet Cutting Machine

Choosing the Right Machine

When selecting a stone slab cut-to-size machine, consider the following factors:

Material Compatibility: Ensure the machine is suitable for the types of stone you'll be processing.

Cutting Speed: Faster machines are ideal for large-scale operations, while slower models may be sufficient for custom, small-batch production.

Automation Level: CNC-enabled machines are better for intricate designs and large-scale projects.

Budget: Advanced features often come at a higher price, but the investment can pay off in long-term efficiency and output quality.

Conclusion

Stone slab cut-to-size machines are indispensable for businesses looking to enhance productivity, precision, and cost-effectiveness in stone fabrication. By automating and optimizing the cutting process, these machines have transformed how stone slabs are used in construction and design projects. Whether you’re a seasoned stone fabricator or a business considering venturing into this industry, investing in a reliable stone slab cut-to-size machine could be a pivotal step toward success. Yongda provides you with different types of stone processing machines, browse our website or contact us for more detailed information.