In the realm of modern stone processing, Stone CNC machining centers have emerged as necessary tools, transforming the way natural and engineered stones are cut, shaped, and carved. These high-tech machines, driven by Computer Numerical Control (CNC) technology, bring unprecedented precision and efficiency to the stone industry.

Stone CNC Machining Centers

A Stone CNC machining center is a sophisticated piece of equipment designed for the precise cutting, shaping, and carving of various types of stone materials. Unlike traditional methods that rely on manual labor or less accurate machinery, CNC technology enables automation and computer-guided precision in stone processing.

Stone CNC machining centers consist of essential components such as a sturdy frame, a cutting spindle, a CNC controller, and a bed where the stone material is securely positioned. The CNC controller is the brain of the system, interpreting digital design files and executing precise movements of the cutting spindle.

Yongda 5-Axis Machining Center

Advantages of Using Stone CNC Machining Centers

Precision and Accuracy: CNC technology ensures unparalleled precision in stone cutting and carving, allowing for intricate designs and detailed patterns that would be challenging with traditional methods. The accuracy of Stone CNC machining centers minimizes material wastage, contributing to cost-effectiveness.

Versatility: Stone CNC machining centers are versatile and can process a wide range of materials, including natural stones like granite and marble, as well as engineered stones like quartz.

Efficiency and Speed: The automation provided by CNC technology significantly speeds up the stone processing workflow, making Stone CNC machining centers highly efficient. Rapid tool changes and multi-axis capabilities further enhance the speed of production.

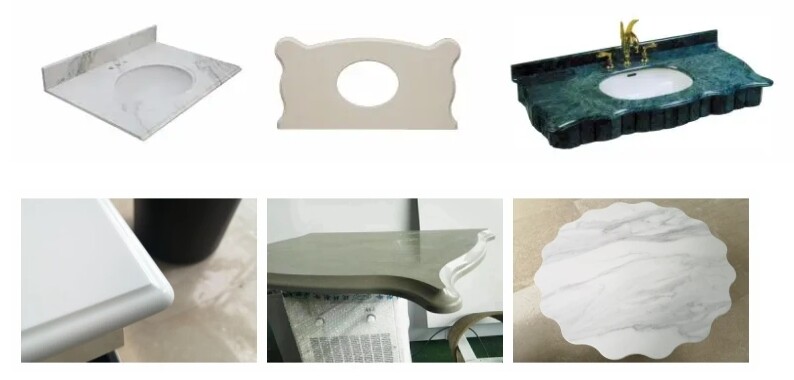

Sample Show: Different Shape and Edge

Stone CNC Machining Center Vs. Traditional Stone Cutting Methods

A Stone CNC machining center differs significantly from traditional stone cutting methods, bringing about a transformative shift in the precision, efficiency, and capabilities of stone processing. Here's a comparison highlighting the distinctions between Stone CNC machining centers and traditional stone-cutting methods:

Automation vs. Manual Labor

● Stone CNC Machining Center

Automation: Operates using Computer Numerical Control (CNC) technology, allowing for automated and computer-guided stone cutting and carving.

Precision: Achieves high precision and accuracy in cutting due to the automated control system.

● Traditional Stone Cutting

Manual Labor: Relies on manual labor and hand tools for cutting and shaping stones, which can be time-consuming and less precise.

Varied Quality: The precision and quality of the cut depend largely on the skill and experience of the operator.

Precision and Accuracy

● Stone CNC Machining Center

Digital Precision: Executes precise movements based on digital design files, ensuring consistent and accurate cuts.

Intricate Designs: Capable of producing intricate designs and complex patterns with a high level of detail.

● Traditional Stone Cutting

Limited Precision: Precision is limited by the skill of the operator and the tools used, resulting in less accurate cuts.

Challenging Designs: Achieving intricate designs can be challenging and may require more time and effort.

Speed and Efficiency

● Stone CNC Machining Center

Automated Workflow: Streamlines the stone processing workflow through automation, leading to faster production.

Rapid Tool Changes: Allows for quick tool changes, enhancing efficiency and reducing downtime.

● Traditional Stone Cutting

Manual Processes: Manual cutting and shaping processes are generally slower, impacting overall efficiency.

Limited Tool Changes: Changing tools manually can be time-consuming and may require additional setup time.

Material Wastage

● Stone CNC Machining Center

Optimized Cutting: Optimizes cutting paths to minimize material wastage, contributing to cost-effectiveness.

Programmed Efficiency: CNC programming ensures efficient use of materials, reducing the need for excess stone.

● Traditional Stone Cutting

Varied Efficiency: The efficiency of material usage depends on the operator's skill, leading to potential wastage.

Manual Optimization: Operators may need to optimize cutting paths to reduce wastage manually.

Versatility

● Stone CNC Machining Center

Wide Range of Materials: Capable of processing various types of stones, including natural stones like granite and marble, as well as engineered stones.

Multiple Tooling Options: Offers versatility through different tooling options for various applications.

● Traditional Stone Cutting

Material Limitations: Limited in terms of the variety of stones that can be efficiently processed.

Tooling Constraints: There may be constraints on tooling options for specific applications.

Consistency

● Stone CNC Machining Center

Consistent Quality: Ensures consistent quality in each piece, regardless of the operator's skill level.

Repeatable Results: Can reproduce the same design with high precision repeatedly.

● Traditional Stone Cutting

Operator Dependence: Quality may vary based on the operator's experience and skill.

Limited Reproducibility: Reproducing exact designs may be challenging due to manual variations.

While traditional stone-cutting methods rely on manual labor and craftsmanship, Stone CNC machining centers leverage advanced technology to provide a level of precision, efficiency, and versatility that significantly surpass traditional approaches.

The automation and digital control offered by CNC technology have propelled stone processing into a new era, changing the industry and expanding the possibilities of what can be achieved in stone cutting and carving. Yongda is committed to providing quality stone CNC machining center, contact us today and find the perfect solution for your project.