The demand for quartz countertops and surfaces has been skyrocketing, thanks to their durability, aesthetic appeal, and low maintenance. To meet this increasing demand, businesses in the stone fabrication industry are turning to advanced machinery, with the quartz slab cut to size machine being a game-changer. This innovative piece of equipment has transformed how quartz slabs are processed, offering unparalleled precision, efficiency, and customization.

What is a Quartz Slab Cut to Size Machine?

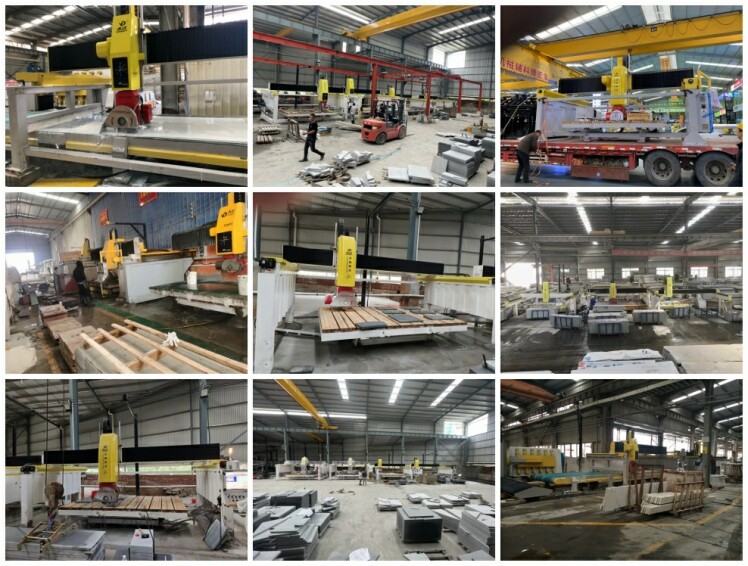

A quartz slab cut to size machine is a specialized tool designed to cut quartz slabs into custom dimensions with precision and efficiency. Unlike traditional cutting methods, which can be time-consuming and prone to errors, these machines utilize advanced technology such as CNC (Computer Numerical Control) systems and water jet or diamond blade cutting mechanisms. This ensures that each cut is accurate, clean, and tailored to the specific requirements of a project.

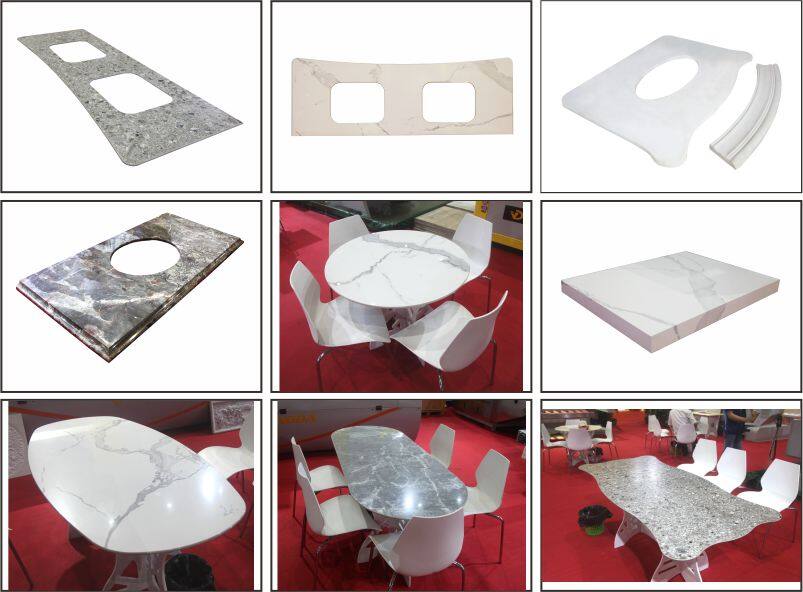

Modern machines often come equipped with automated systems that allow operators to upload design specifications and let the machine handle the rest. From kitchen countertops to custom vanity tops, these machines can handle a wide range of applications, ensuring that the final product meets the exact needs of clients.

Key Features of Quartz Slab Cut to Size Machines

Precision Cutting: These machines utilize CNC technology, enabling precise cuts that minimize waste and ensure consistent quality. This precision is especially important when dealing with high-value materials like quartz, where errors can be costly.

Versatility: A quartz slab cut to size machine can handle various cutting techniques, including straight cuts, beveled edges, and complex shapes. This versatility makes it an indispensable tool for creating intricate designs.

High Efficiency: By automating the cutting process, these machines significantly reduce production time compared to manual methods. This efficiency allows businesses to handle larger volumes of work, boosting productivity and profitability.

User-Friendly Interface: Most modern machines feature intuitive interfaces that make them easy to operate, even for those with limited technical expertise. Operators can program the desired dimensions, and the machine takes care of the rest.

Durability and Reliability: Built with high-quality materials and advanced engineering, these machines are designed to withstand the demands of industrial use. Regular maintenance ensures a long service life, making them a wise investment.

Benefits of Using a Quartz Slab Cut to Size Machine

Enhanced Accuracy: Manual cutting methods often result in uneven edges or inconsistent measurements. With a quartz slab cut to size machine, these issues become a thing of the past. The machine’s precision ensures a perfect fit for every piece, which is critical for achieving seamless installations.

Reduced Waste: Quartz slabs are expensive, and wasting material can significantly impact a business’s bottom line. These machines optimize the cutting process, minimizing waste and maximizing the usable area of each slab.

Cost Efficiency: Although the initial investment in a quartz slab cut to size machine may be substantial, the long-term savings are considerable. Reduced labor costs, faster turnaround times, and less material wastage all contribute to a higher return on investment.

Customization Capabilities: Whether a client wants a unique countertop shape or a complex pattern, these machines make customization straightforward. The ability to deliver bespoke designs gives businesses a competitive edge in the market.

Improved Safety: Manual cutting methods often expose workers to sharp tools and heavy materials, increasing the risk of accidents. By automating the process, these machines enhance workplace safety and reduce the likelihood of injuries.

Applications in the Stone Fabrication Industry

Its ability to handle diverse projects makes it a valuable asset for businesses catering to both residential and commercial clients. The quartz slab cut to size machine is versatile enough to be used in various applications, including:

Residential Projects: Custom kitchen countertops, bathroom vanities, and tabletops.

Commercial Spaces: Reception desks, conference tables, and retail displays.

Architectural Designs: Wall claddings, stairs, and decorative elements.

Choosing the Right Quartz Slab Cut to Size Machine

When selecting a quartz slab cut to size machine, businesses should consider the following factors:

Cutting Mechanism: Water jet cutting is ideal for intricate designs, while diamond blade cutting is better suited for straight cuts and faster processing.

Machine Size: The machine should be large enough to accommodate the dimensions of the quartz slabs you typically work with.

Automation Level: Advanced automation features can streamline operations, but they may come at a higher cost.

Support and Maintenance: Choose a manufacturer that offers excellent customer support and regular maintenance services to ensure your machine operates at peak performance.

Conclusion

The quartz slab cut to size machine represents a significant advancement in the stone fabrication industry. By combining precision, efficiency, and versatility, these machines have become essential for businesses looking to stay competitive in a growing market. Whether you’re a small fabricator or a large-scale manufacturer, investing in this technology can help you deliver high-quality products, reduce costs, and exceed client expectations.