Large slab cutting machines are essential tools in the stone and construction industries, designed to efficiently cut large stone blocks into manageable slabs. These machines enhance productivity, precision, and versatility in various applications, from quarrying to architectural installations. This article explores the types, components, operation, and advantages of large slab cutting machines.

Types of Large Slab Cutting Machines

Wire Saw Machines

Wire saws utilize a metal wire or cable coated with diamond-tipped beads to cut through stone with high precision. They are particularly effective for intricate shapes and large blocks, making them a popular choice in quarrying and construction.

Block Cutting Machines

These machines are specifically designed to cut large stone blocks into smaller pieces. They typically feature powerful diamond-tipped blades or saws, ensuring clean cuts and efficient processing.

Bridge Saws

Bridge saws are equipped with a large circular blade mounted on a bridge that moves along rails. This design allows for precise horizontal and vertical cuts of stone slabs, making them ideal for producing uniform slabs.

CNC Routers

Computer Numerical Control (CNC) routers automate the cutting process, allowing for intricate designs and high precision. These machines can adjust cutting parameters based on digital designs, enhancing efficiency and reducing waste.

Waterjet Cutters

Using high-pressure water jets mixed with abrasive materials, waterjet cutters can achieve intricate cuts without generating heat that could damage the stone. This method is ideal for delicate materials and complex designs.

Advantages of Large Slab Cutting Machines

Efficiency: These machines significantly reduce cutting time compared to manual methods, enhancing overall productivity.

Precision: Advanced technology allows for accurate cuts with uniform dimensions, crucial for high-quality installations.

Versatility: Capable of handling various materials and shapes, making them suitable for diverse applications in construction and design.

Reduced Labor Costs: Automation minimizes reliance on manual labor, allowing businesses to allocate resources more effectively.

Applications of Large Slab Cutting Machines

Large slab cutting machines are integral to various industries, facilitating the precise and efficient cutting of large materials, particularly stone and concrete. Their applications span across multiple sectors, each benefiting from the machines' capabilities to enhance productivity and accuracy.

Here are some key applications:

Construction Industry

Large slab cutting machines are extensively used in the construction sector for fabricating structural components. They efficiently cut thick steel plates for beams, columns, and trusses, ensuring high precision essential for structural integrity. This capability allows construction companies to produce components that fit together perfectly during assembly, thereby enhancing safety and stability in buildings and bridges.

Quarrying and Stone Fabrication

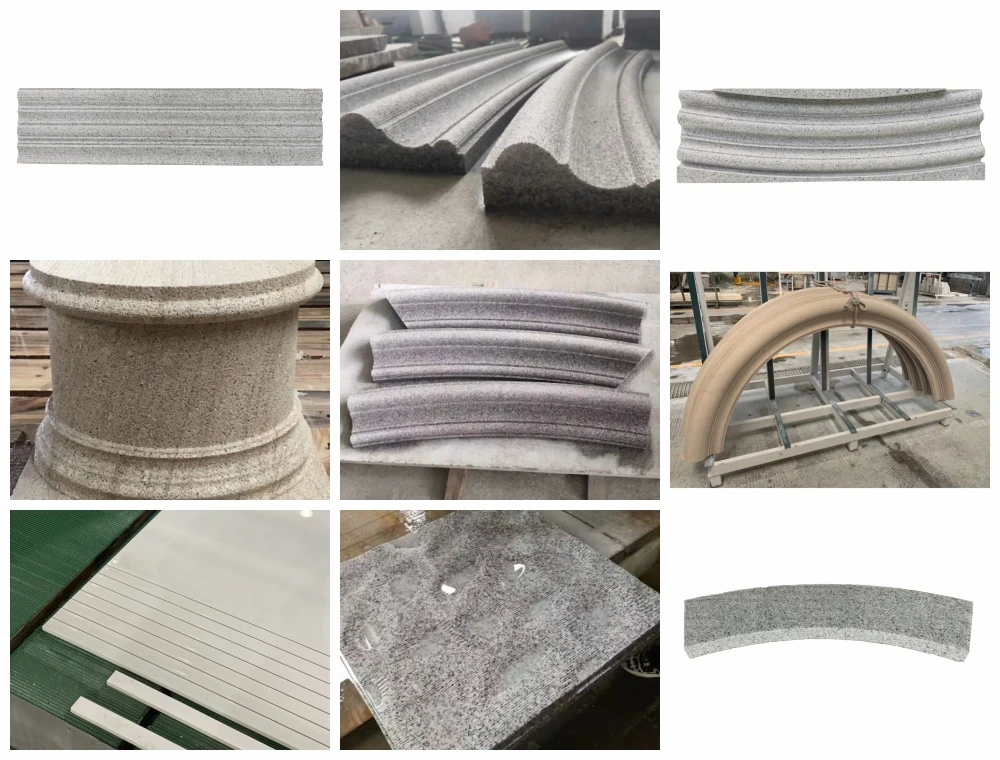

In the quarrying industry, these machines are vital for transforming large stone blocks into manageable slabs. They enable the cutting of various types of stone, including granite and marble, into specific dimensions for use in countertops, flooring, and decorative elements. The precision offered by slab cutting machines minimizes waste and maximizes the yield from raw stone blocks.

Architectural Applications

Architects and designers utilize large slab cutting machines to create intricate designs in stone and concrete for aesthetic features in buildings. These machines allow for detailed patterns and shapes that enhance the visual appeal of architectural elements such as facades, flooring, and sculptures.

Comparison of Large Slab Cutting Machines and Traditional Cutting Methods

Large slab cutting machines have transformed the way materials are processed in various industries, offering significant advantages over traditional cutting methods.

| Criteria | Large Slab Cutting Machines | Traditional Cutting Methods |

| Efficiency | High-speed operation; reduced manual intervention | Slower production; longer setup times |

| Precision | Superior accuracy (±0.005 inches); minimal distortion | Reasonable accuracy; prone to human error |

| Cost | Higher initial investment but lower operational costs over time | Lower upfront costs but higher long-term expenses |

| Versatility | Can cut various materials; capable of complex shapes | Limited to specific tasks; less adaptable |

| Safety | Enhanced safety features; reduced risk of injury | Higher risk of injury due to manual handling |

Conclusion

Large slab cutting machines serve a multitude of applications across various industries by providing efficient, precise cutting solutions that enhance productivity and quality. Their versatility makes them indispensable tools in the construction, manufacturing, and design sectors, driving innovation and efficiency in material processing. As technology advances, these machines will likely continue to evolve, further expanding their applications and capabilities in industrial settings.