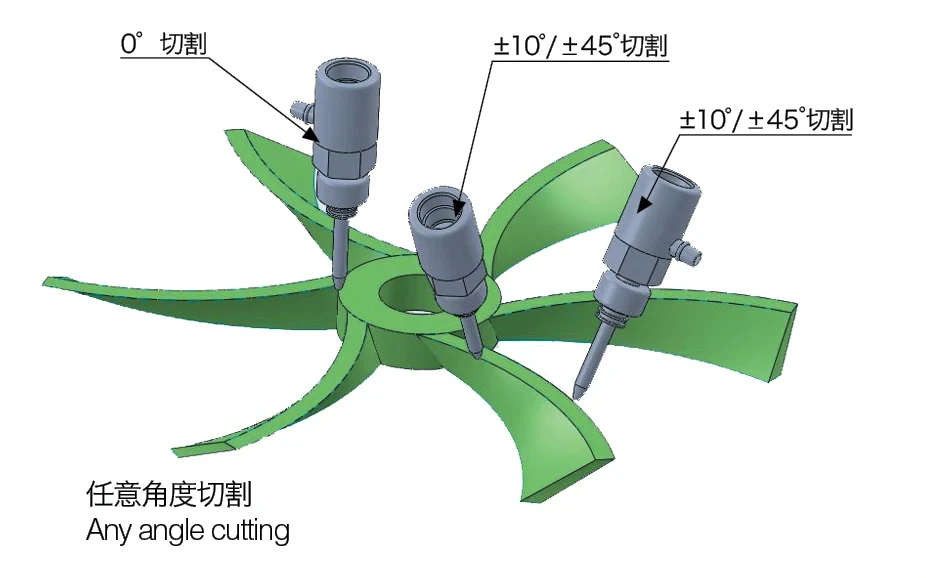

It easily achieves arc plate cutting, cylinder cutting, and spiral leaf cutting ... making the impossible possible. Waterjet cutting machine can cut the arbitrary curve and arbitrary angle, curve, and angle changing is controlled by a computer which makes it more stable.

AC 5 Axis Waterjet Cutting Machine

● 5 axis CNC waterjet cutting machine adopts AC axis design, real 5 axis (X. Y. Z. A.C) move.

● Structure tight for the Waterproof and dustproof. electrical wiring has a tidier and more clear layout.

● All spare parts are processed by Japanese high-precision CNC, ensuring high accuracy of the 5 axis CNC waterjet.

● 5 axis CNC waterjet cutter adopts an international high-end brand servo motor and servo driver to make the control accuracy higher.

● Reasonable design, evenly the force, effectively improving the water jet's operating life and reliability.

Waterjet cutting machines are a popular choice for precision cutting in a variety of industries, including aerospace, automotive, and manufacturing. One question that often arises is whether the quality of the water used in the machine is important. The answer is a resounding yes.

Why does the quality of water affect the waterjet cutting machine?

The water used in a waterjet cutting machine plays a critical role in the cutting process. It is not just a simple matter of filling the tank with tap water and pressing a button. The water used in the waterjet cutting machine must meet certain specifications to ensure optimal cutting performance and protect the machine from damage.

Hardness

One of the primary concerns when it comes to water quality is hardness. Hard water contains high levels of minerals, particularly calcium, and magnesium, which can form deposits and scale inside the machine. This can lead to clogs, damage to the machine's components, and reduced cutting performance. To prevent these issues, many waterjet cutting machines require the use of soft water or water that has been treated to remove minerals.

Purity

Another important consideration is the purity of the water. Impurities in the water, such as chlorine, fluoride, and heavy metals, can have a negative impact on the cutting process. Impurities can cause the machine's components to corrode, resulting in damage and reduced performance. To ensure optimal cutting performance, it is important to use water that has been treated to remove impurities.

Temperature

The temperature of the water is also important. Water that is too cold can cause the machine's components to contract, leading to damage and reduced performance. On the other hand, water that is too hot can cause the machine to overheat, which can also result in damage and reduced performance. It is important to maintain the water at a consistent temperature to ensure optimal cutting performance.

Water Pressure

In addition to these factors, the pressure of the water also plays a critical role in the cutting process. Waterjet cutting machines rely on high-pressure water to cut through materials. If the pressure of the water is too low, the machine will not be able to cut through the material effectively.

On the other hand, if the pressure is too high, it can cause the material to erode or even damage the machine itself. It is important to use water that is capable of producing the required pressure for the waterjet cutter to operate at its optimal level.

In conclusion, the water used in a waterjet cutting machine is of critical importance to the cutting process. To ensure optimal cutting performance and protect the machine from damage, it is important to use water that meets certain specifications for hardness, purity, temperature, and pressure. By doing so, you can achieve precise cuts and extend the lifespan of your machine.

Yongda Waterjet: waterjet cutting machine for sale

YONGDA water jet design concept: high accuracy, high efficiency, energy saving, simple maintenance, easy operation, waterproof, dustproof, etc.

Spare parts are processed by advanced imported equipment, the waterjet cutting head's dynamic accuracy is tested by super high precision instruments, and the processing equipment, instruments, and precision of resetting reach the leading level of the country.

As one of the waterjet cutting machine suppliers in China, YONGDA water jet makes you feel more stable, more reliable, and more satisfied. Here contact us for more detail.