CNC water jet cutting machines are versatile and efficient tools used in a wide range of industries for cutting and shaping a variety of materials.

The key advantages of CNC water jet cutting machines include precision, versatility (ability to cut various materials), minimal heat-affected zones, and the ability to create intricate designs, making them valuable tools across a broad spectrum of industries.

3 Axis Waterjet Cutting Machine

Here are some of the industries that benefit the most from CNC water jet cutting machines:

Manufacturing

The manufacturing industry is perhaps the most significant beneficiary of CNC waterjet cutting machines. These machines such as 5 axis bridge cutting machines, porcelain cutting waterjet, kitchen countertop edge profiling machines, ceramic slab cutting machines, and ceramic bullnose machines are used to cut and shape a wide range of materials such as plastics, composites, and ceramics.

CNC water jet cutting machines are essential for manufacturing parts for a variety of industries, including aerospace, automotive, and medical.

Aerospace

The aerospace industry is one of the major beneficiaries of CNC water jet cutting machines. These machines can be used to cut and shape different types of metals and alloys, including titanium, aluminum, and more.

CNC waterjet cutters provide a precise and efficient way to cut intricate shapes and designs for aircraft parts.

Automotive

CNC water jet cutting machines are also widely used in the automotive industry for cutting and shaping various parts such as gears, brake discs, and engine components.

The ability to cut through various materials like steel, aluminum, and plastics makes CNC waterjet cutting machines a valuable asset in the automotive industry.

Architectural

The architectural industry benefits from CNC water jet cutting machines because of their ability to cut and shape various materials such as marble, granite, and glass.

Marble slab cut to size machines, granite slab cut to size machines, glass waterjet cutting, etc. allow architects and designers to create intricate designs and shapes that would be impossible with traditional cutting methods.

Medical

The medical industry is another industry that benefits from CNC water jet cutting machines. CNC water jet cutting machines can produce complex designs and shapes with high precision, making them essential for medical device manufacturing.

In a word, CNC waterjet cutting machines are valuable assets to various industries. These machines are versatile, efficient, and capable of cutting and shaping a wide range of materials with precision and are valuable assets in many industries.

5 Axis Waterjet Cutting Machine for Sale

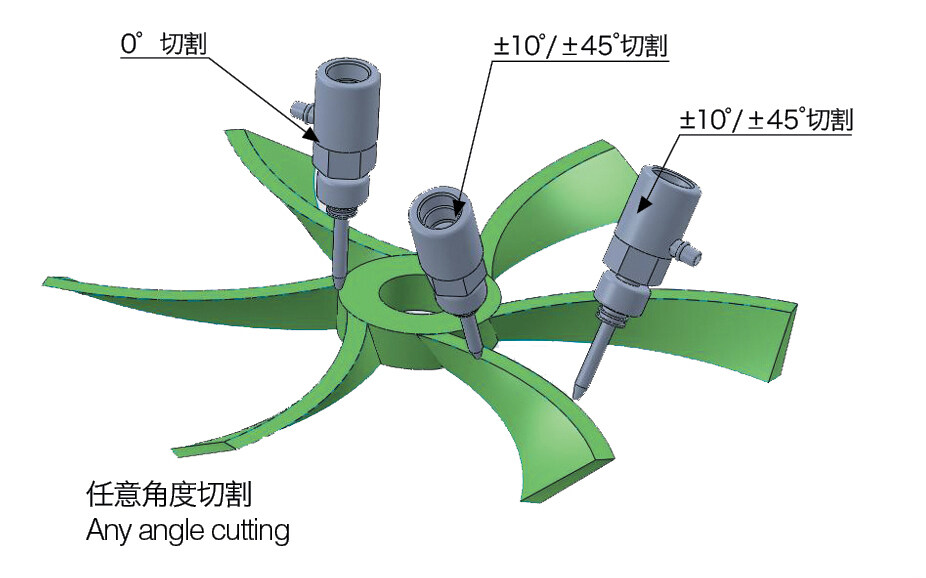

5 axis CNC waterjet easily achieves arc plate cutting, cylinder cutting, and spiral leaf cutting... making the impossible possible.

AC 5 axis waterjet cutting machine can cut an arbitrary curve and arbitrary angle, curve, and angle changing is controlled by a computer which makes it more stable.

Advantages of AC 5 Axis Waterjet Cutting Machine

● 5-axis CNC waterjet cutting machine adopts AC axis design, real 5-axis (X. Y. Z. A.C) move.

● Structure tight for the Waterproof and dustproof. electrical wiring has a tidier and more clear layout.

● All spare parts are processed by Japanese high-precision CNC, ensuring high accuracy of the 5-axis CNC waterjet.

● 5 axis CNC waterjet cutter adopts an international high-end brand servo motor and servo driver to make the control accuracy higher.

● Reasonable design, evenly the force, effectively improving the water jet's operating life and reliability.

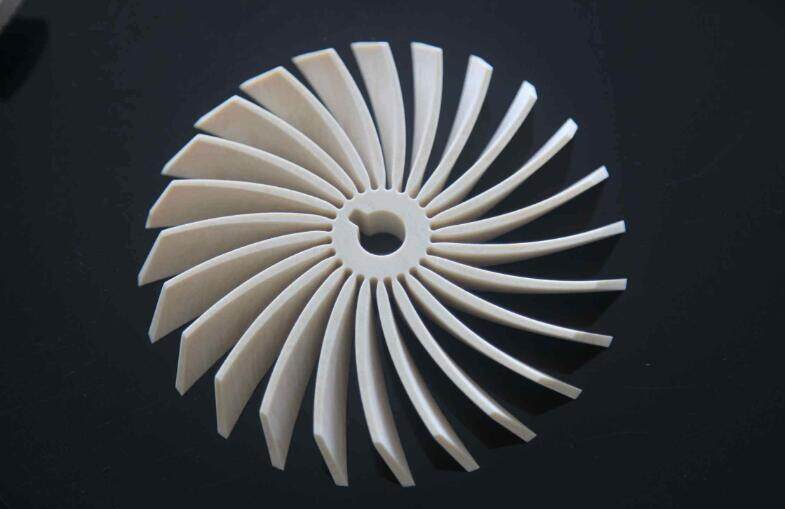

SAMPLE SHOW: 45° CUTTING, MITRE

APPLICATION: WASHING TOP MITRE, COUNTERTOPS MITRE, KITCHENTOPS MITRE

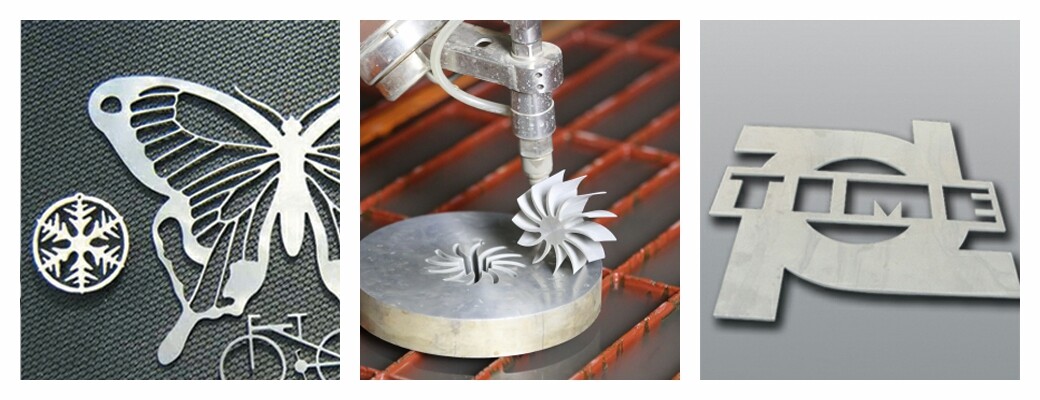

SAMPLE SHOW: METAL CUTTING

YONGDA waterjet cutter design concept: high accuracy, high efficiency, energy saving, simple maintenance, easy operation, waterproof, dustproof, etc.

Spare parts are processed by advanced imported equipment, the head's dynamic accuracy is tested by super high precision instruments, and the processing equipment, instruments, and precision of resetting reach the leading level of the country.

YONGDA waterjet makes you feel more stable, more reliable, and more satisfied.