Bridge cutting machines are known for their high precision and accuracy in cutting various materials. They are commonly used in the construction and manufacturing industries for cutting large and heavy materials such as stone, granite, and other natural or engineered materials. Bridge cutting machines are versatile and find applications in various industries.

How Accurate Are Bridge Cutting Machines?

Compared to manual cutting methods, bridge-cutting machines offer significantly higher levels of accuracy. The automation and computer numerical control (CNC) technology in these machines eliminates human errors, ensuring consistent and precise cuts. Bridge-cutting machines outperform traditional saws and handheld tools, providing better results in terms of dimensional accuracy and surface finish.

When you are considering investing in a bridge cutter, you may be wondering about its cutting accuracy. Bridge-cutting machines are designed to provide high accuracy, with some models capable of achieving tolerances within fractions of a millimeter. Some bridge cutters are designed for faster cutting to boost productivity, while others prioritize precision over speed.

It is important to note that the accuracy of a bridge cutter can be affected by a number of factors, including the quality of the machine, the cutting mechanism, the material properties, the operator's skills, and routine maintenance.

Machine Quality: The accuracy of the cutting process depends on the quality and precision of the machine itself. Higher-end bridge cutters tend to offer better accuracy due to improved engineering and more advanced control systems.

Cutting Mechanism: The cutting mechanism, which could involve diamond-tipped blades or other specialized tools, also impacts accuracy.

Material Characteristics: The type and properties of the material being cut can affect accuracy. Harder materials might require different cutting techniques to achieve the desired precision.

Operator Skill: The operator's expertise and familiarity with the machine play a vital role in achieving accurate cuts. Skilled operators can optimize settings and parameters for specific materials and cutting tasks.

Maintenance: Regular maintenance of the bridge-cutting machine is crucial for maintaining accuracy over time. Any wear and tear on components can lead to decreased precision.

Many modern bridge-cutting machines are equipped with Computer Numerical Control (CNC) systems. CNC bridge saw allows for precise control of the cutting process, enhancing accuracy and repeatability. Sophisticated software allows operators to simulate the cutting process before execution, identifying any potential issues and ensuring precise results.

5 Axis CNC Bridge Saw for Sale

Can Bridge-Cutting Machines Perform Complex Cuts with High Accuracy?

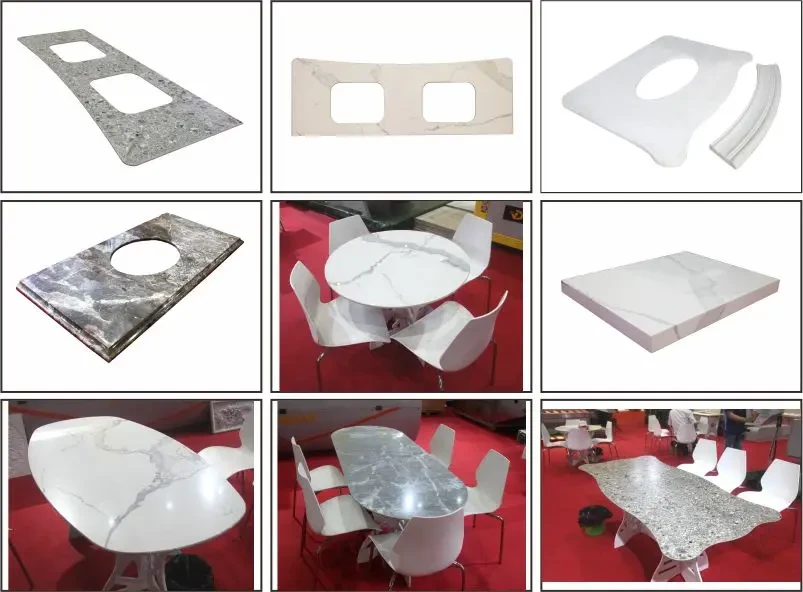

Modern bridge-cutting machines are equipped with advanced CNC technology, enabling them to execute complex cuts with exceptional accuracy. With the right programming and tooling, these machines can create intricate shapes and designs on various materials, such as stone, marble, granite, and engineered stone.

What Is the Typical Accuracy Level of Bridge Cutting Machines?

Bridge-cutting machines are designed to achieve high levels of accuracy. The typical accuracy level of these machines can vary depending on the make and model, but most modern machines can achieve cutting tolerances within 0.1 to 0.5 millimeters (mm). Some advanced models may even achieve higher precision levels of 0.05 to 0.1 mm.

How Important Is Regular Maintenance for Preserving Accuracy?

Regular maintenance is crucial for preserving the accuracy and performance of bridge-cutting machines. Dust and debris can accumulate over time, affecting the machine's moving parts and calibration. Routine maintenance, including cleaning, lubrication, and calibration checks, should be carried out as per the manufacturer's guidelines to ensure optimal accuracy and longevity of the machine.

Final Words

In a word, the accuracy and features of bridge cutters may vary depending on the specific model and manufacturer. Consulting with the bridge cutting machine manufacturers and understanding the features of the machine will help you determine the best equipment for your cutting needs.

Investing in a reliable machine will significantly increase the chances of achieving an accurate and consistent cut to meet your cutting needs. Contact Yongda today for more information on bridge cutters and to find the perfect solution for your project.