There are two main types of decorative stone used in building decoration: marble and granite. To process the facing stone blocks into building decorative panels, the main processes are sawing, grinding and polishing, cutting the finished panels, trimming, chamfering, and grooving.

Whether it is natural stone or artificial stone, it is necessary to be processed before being used in the construction industry. Related stone cutting machines are CNC water jet cutting machines, bridge cutting machines, stone CNC machining centers, grinding & polishing machines, and other ceramic stone machines. The treated stone can better reflect the decorative function and function.

However, stone, especially natural stone, will be affected by a number of factors during the molding process, resulting in it is not completely homogeneous, which will naturally affect the subsequent processing procedures. So what are the factors that affect stone processing?

Yongda Stone Machine

Hardness

In general, the resistance to abrasion and cutting resistance increases with the hardness of the stone. The higher the hardness of the stone, the higher the requirements for processing tools and stone work cutting machines.

Composition

The material composition of the stone consists of mineral composition and chemical composition, and its processability varies. In terms of the chemical composition of the stone, the higher the content of Si02, the more difficult it is to process.

Structure

In general, a homogeneous stone is easier to process than an uneven stone; a fine-grained stone has a higher polishing quality than a flaky stone; a dense stone has a higher gloss than a loose stone. In addition, the chosen stone processing tools as well as the process parameters are influencing factors that must be considered.

It Is Necessary to Choose the Right Stone Processing Machine

Choosing a high-quality, reliable and suitable processing machine will greatly reduce the trouble of stone processing, improve processing efficiency and reduce processing costs.

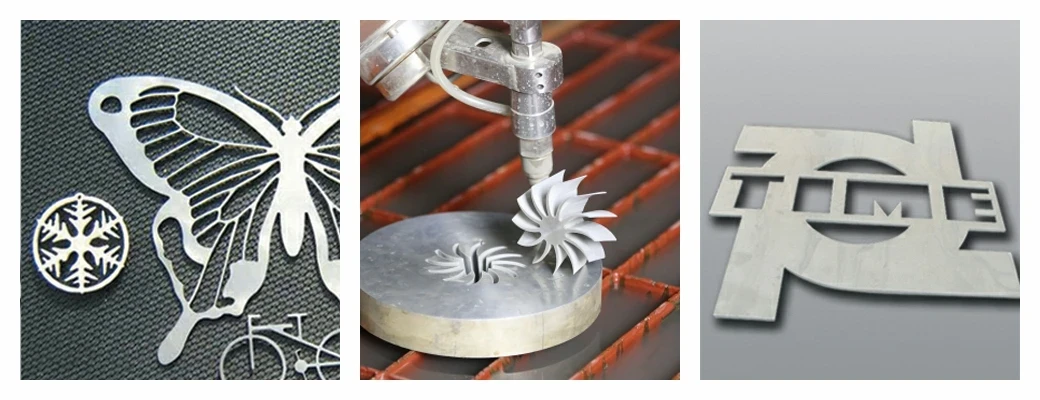

Waterjet Cutting Machine

The waterjet cutting machine easily achieves circular plate cutting, cylindrical cutting, and spiral blade cutting, making the impossible possible. AC 5 axis waterjet cutting machine head can cut any curve and any angle, the curve, and angle change are controlled by a computer, and the processing is more efficient and stable.

AC 5 Axis Waterjet Cutting Machine

Stone CNC Machine Center

Advanced, multi-functional entire computer numerical control processing center, not only can process various materials, such as granite kitchen table top edge processing, marble kitchen table top edge processing, ceramic, glass, even micro spar, and steel but also can produce various exquisite curve and luxurious model basin board and kitchenware board, as well as various complex relief carving.

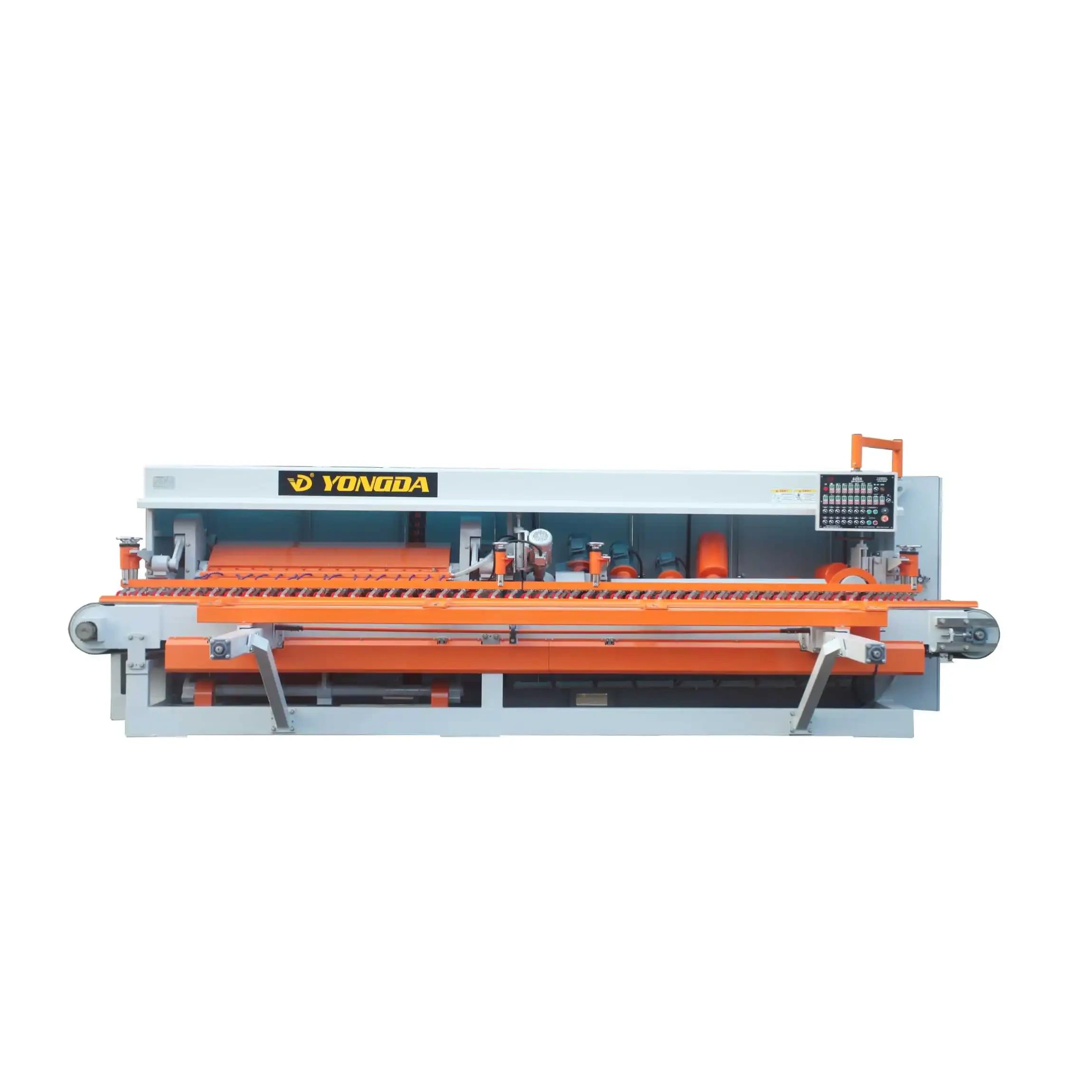

Grinding & Polishing Machine

A ceramic arc edge polishing machine can process various edges such as 90-degree arc edges, straight and bevel edges, straight edges with chamfering, etc. With fast processing speed, low processing cost, and various edges, ceramic arc edge polishing machine is highly appreciated by new and old customers.

Ceramic Arc Edge Polishing Machine

CNC Engraving Machine

The CNC multifunctional engraving machine can engrave any design such as patterns, and letters on stone, ceramic, and glass.

CNC multifunctional engraving machine is an ideal tool in the engraving industry with its high accuracy, simple CNC operation, and high working efficiency. The optional sizes of bridge height are suitable for different thicknesses of the material, greatly enlarging your design applications.

CNC Engraving Machine for Sale

Conclusion

Understanding the main factors that affect stone processing has a positive effect on your processing procedures. Choosing the right processing machine can improve your production line, boost sales, and contribute to business success.

YONGDA is dedicated to Designing, Manufacturing, and Sales of deep-processing equipment for stone, ceramic, glass, and metal. Please trust us to have a solution that will satisfy you.