Bridge cutting machines and laser cutting machines are both valuable tools in the field of precision cutting, but they have distinct differences in terms of functionality, applications, and cutting mechanisms.

Bridge Cutting Machines

● Cutting Mechanism

Bridge cutting machines utilize physical force and abrasive materials (such as diamond blades or waterjets) to cut through materials. The cutting head moves along a bridge-like structure, delivering powerful and precise cutting action.

● Material Compatibility

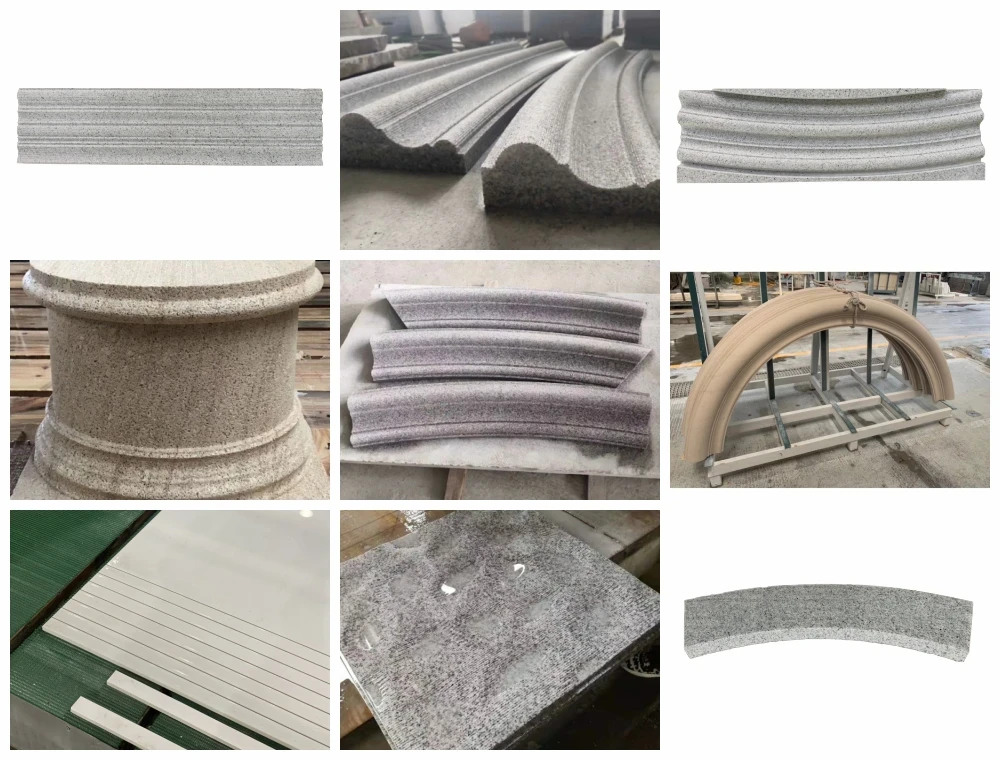

Bridge cutting machines are primarily used for heavy-duty cutting tasks, particularly in industries like construction and stone fabrication. 5 axis bridge cutting machine and 4 axis bridge cutting machine excel in cutting thick and heavy materials such as stones, granite, marble, and composites.

● Precision and Accuracy

Bridge cutting machines offer exceptional precision and accuracy, enabling intricate cuts, beveling, and shaping of materials. The use of an advanced 4 axis CNC bridge cutter or 5 axis CNC bridge cutter further enhances the precision and repeatability of cuts.

● Cutting Speed

Bridge cutting machines provide high cutting speeds, allowing for efficient production and reduced turnaround times. However, the cutting speed may vary depending on the material thickness and the type of cutting mechanism employed.

● Flexibility and Versatility

4 axis CNC bridge cutter or 5 axis CNC bridge cutter excels in cutting thick and heavy materials but may have limitations in terms of flexibility and adaptability for intricate or complex cuts.

5 axis CNC bridge saw for sale

Laser Cutting Machines

● Cutting Mechanism

Laser-cutting machines employ a highly focused laser beam to cut through materials. The laser beam melts or vaporizes the material along the designated cutting path, creating precise cuts without physical contact.

● Material Compatibility

Laser-cutting machines are highly versatile and can cut a wide range of materials, including metals, plastics, fabrics, wood, etc. They find applications in various industries such as manufacturing, automotive, aerospace, and electronics.

● Precision and Accuracy

The focused laser beam allows for intricate cuts, fine contours, and intricate designs, making them suitable for applications that require high precision and intricate detailing.

● Cutting Speed

The speed at which the laser beam moves across the material determines the cutting speed, which can be adjusted as per the requirements of the application.

● Flexibility and Versatility

Laser-cutting machines can create intricate and complex designs with ease, making them suitable for applications that require detailed and intricate cuts.

Conclusion

Bridge cutting machines and laser-cutting machines offer different cutting mechanisms, material compatibilities, precision levels, cutting speeds, and flexibility.

Bridge cutting machines excel in the heavy-duty cutting of thick materials, while laser-cutting machines provide exceptional precision, versatility, and the ability to cut a wide range of materials with intricate detailing.

The right bridge cutter can improve your production line, boost sales, and contribute to business success. Understanding these distinctions is crucial for selecting the most suitable cutting technology for specific applications. Contact Yongda Machinery here for more details on the bridge cutting machine.