Proper use of bridge cutting machines can improve your production line, increase productivity, boost sales, and contribute to business success. How can a bridge cutting machine improve processing efficiency? Read on to learn more.

A bridge cutting machine can improve processing efficiency in several ways:

High Production Speed

Bridge cutting machines are designed to cut through materials quickly and efficiently. They utilize powerful motors and cutting blades to ensure fast processing times, enabling higher production throughput compared to manual or traditional cutting methods.

Precise Cutting

Bridge cutting machines are equipped with advanced cutting tools and technologies that enable precise and accurate cuts. The precision reduces the need for manual adjustments and minimizes material wastage, thereby improving overall efficiency.

Automated Operation

Bridge cutting machines often feature automated controls and programmable settings. Automation reduces the need for manual intervention during the cutting process, allowing operators to focus on other tasks. Automated operation reduces human error, increases consistency, and enhances overall productivity. Operators can program the machine to perform specific cutting patterns, shapes, or sequences, streamlining the process and improving overall efficiency.

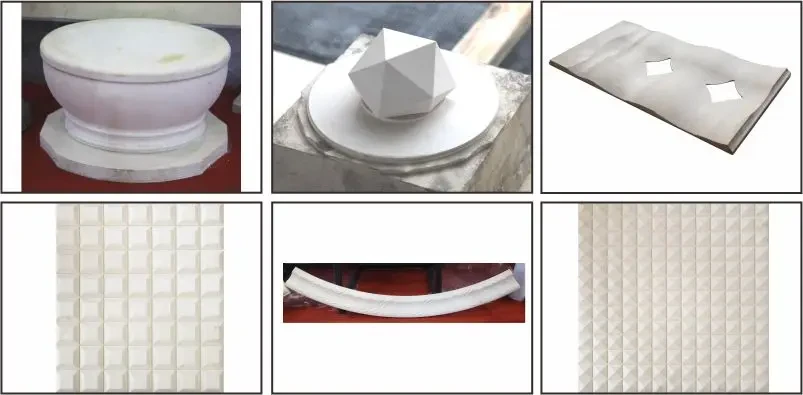

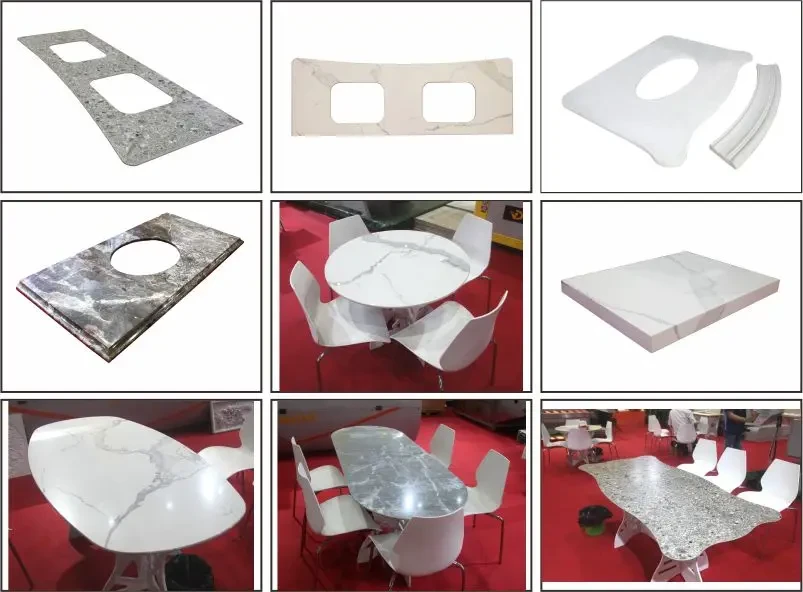

Multi-Axis Cutting

Many bridge cutting machines offer multi-axis cutting capabilities, allowing them to perform complex cuts and shapes. This versatility enables the 4 axis bridge cutting machine or 5 axis bridge cutting machine to handle a wide range of cutting tasks, reducing the need for additional equipment and streamlining the production process. Additionally, bridge cutting machines often come equipped with various cutting blades, tools, or attachments, enabling them to handle different types of materials and cutting requirements.

Increased Safety

Bridge cutting machines are equipped with safety features and guards to protect operators during operation. Safety measures reduce the risk of accidents and injuries, providing a secure working environment and maintaining a steady workflow.

Material Optimization

Bridge cutting machines are adept at optimizing material usage, which is especially crucial when working with expensive or limited resources. Bridge cutting machines often include features for efficient material handling. Through precise cutting and nesting algorithms, these machines can maximize the utilization of raw materials, minimizing waste and reducing production costs.

Data Integration and Analysis

Advanced bridge cutting machines may incorporate data integration and analysis capabilities. It allows operators to monitor and optimize cutting processes, identify bottlenecks or inefficiencies, and make informed decisions to enhance overall efficiency and productivity.

In a word, the mentioned above collectively contribute to increased productivity, reduced waste, and streamlined operations in various industries that require cutting and shaping of materials.

Looking for a quality 4 axis bridge cutting machine or 5 axis bridge cutting machine? Yongda is one of the professional and trustworthy bridge cutting machine manufacturers, we will provide you with quality products and services at reasonable prices.