Stone CNC machining centers have changed the construction industry by providing precision, efficiency, and versatility in processing various stone materials. These advanced machines are used in a wide range of applications, from architectural elements to intricate decorative features. This article explores the common applications of stone CNC machining centers in the construction industry, highlighting their impact on modern construction practices.

Architectural Elements

One of the primary applications of stone CNC machining centers in the construction industry is the creation of architectural elements. These elements include:

Columns and Capitals: Stone CNC machines are used to carve intricate designs on columns and capitals, which are essential components in classical and modern architecture. The precision of CNC technology ensures that each piece is identical, maintaining consistency across large projects.

Facades and Cladding: CNC machining centers are employed to produce stone facades and cladding panels with precise dimensions and intricate patterns. This application enhances the aesthetic appeal of buildings while providing durable and weather-resistant surfaces.

Balustrades and Railings: Balustrades and railings made from stone add elegance and safety to staircases, balconies, and terraces. CNC machines can produce these elements with detailed designs and smooth finishes, ensuring both functionality and visual appeal.

Decorative Features

Stone CNC machining centers are also widely used to create decorative features that enhance the beauty and uniqueness of construction projects. They include:

Reliefs and Sculptures: CNC machines can carve detailed reliefs and sculptures from stone, allowing architects and designers to incorporate artistic elements into their projects. These features can be used in both interior and exterior spaces, adding a touch of sophistication and cultural significance.

Mosaics and Inlays: Stone CNC machining centers are capable of producing intricate mosaics and inlays with high precision. These decorative elements are often used in flooring, wall panels, and countertops, creating visually stunning patterns and designs.

Functional Components

Beyond decorative and architectural elements, stone CNC machining centers are used to produce functional components that are essential in construction projects. These components include:

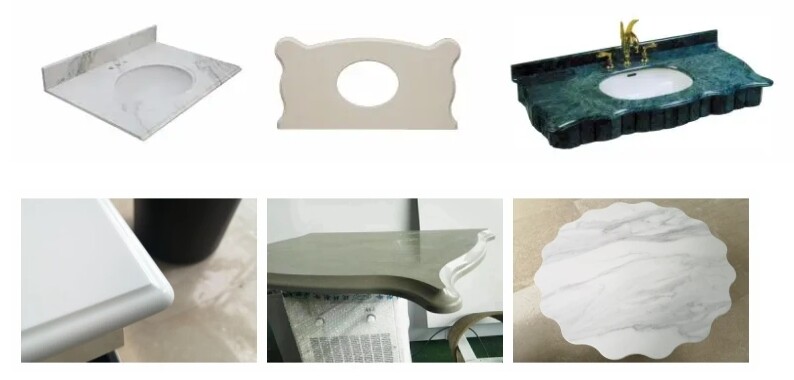

Countertops and Vanity Tops: CNC machines are widely used to cut and polish stone slabs for countertops and vanity tops. The precision of CNC technology ensures that these surfaces fit perfectly within their designated spaces, providing both functionality and aesthetic appeal.

Flooring and Paving: Stone CNC machining centers are employed to produce flooring tiles and paving stones with precise dimensions and consistent quality. This application is crucial for creating durable and visually appealing surfaces in both indoor and outdoor spaces.

Staircases: CNC machines can carve and shape stone steps and risers for staircases, ensuring uniformity and precision. Stone staircases add a touch of elegance and durability to residential and commercial buildings.

Custom and Complex Projects

The versatility of stone CNC machining centers allows for the execution of custom and complex projects that would be challenging or impossible with traditional methods. These projects include:

Custom Architectural Designs: Architects and designers can leverage CNC technology to bring their unique and complex designs to life. CNC machines can handle intricate geometries and detailed patterns, enabling the creation of custom architectural elements that stand out.

Restoration and Replication: CNC machining centers are invaluable in the restoration and replication of historical stonework. The precision of CNC technology allows for the accurate reproduction of intricate details, ensuring that restored elements match the original designs.

Large-Scale Installations: For large-scale installations, such as public monuments and urban landscaping projects, CNC machines provide the efficiency and precision needed to produce high-quality stone components. These installations often require complex shapes and detailed finishes, which CNC technology can deliver.

Conclusion

Stone CNC machining centers have become indispensable tools in the construction industry, offering unparalleled precision, efficiency, and versatility. From architectural elements and decorative features to functional components and custom projects, these advanced machines have transformed the way stone materials are processed and utilized in construction. As technology continues to advance, the applications of stone CNC machining centers are expected to expand, further enhancing the capabilities and creativity of architects, designers, and builders.