Categorys

Hot Product

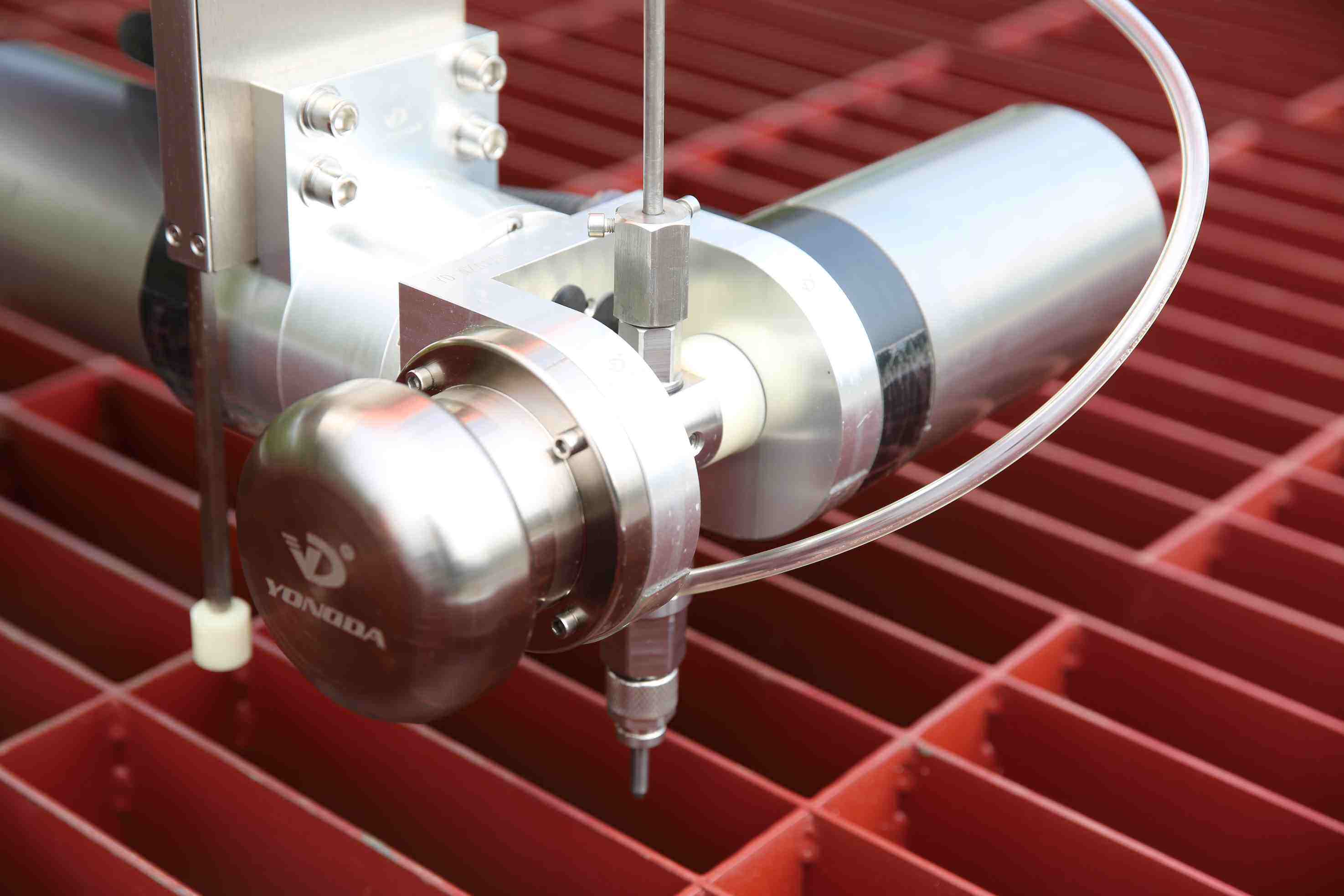

AB 5 Axis Waterjet Cutting Machine

1. Angle cutting, solve the headache of half bottom cutting surface bumpy which affects the pattern quality, no need to grind the edge in the stone pattern craft processing, reduce production steps, lower labor cost.

2. Can process complex products such as arc plate cutting and cylinder pattern.

3. Fast cutting speed, turning without stop and without dot.

Advantages of AB 5 AXIS cutting head:

l Adopt AB axis design, realize 5 axis (X. Y. Z. A.B) move.

l Structure more tight for the Waterproof and dust proof. electrical wiring has a tidier and clear layout.

l All spare parts are processed by Japan high precision CNC, ensure high accuracy of the machine.

l Adopt international high-end brand servo motor and servo driver to make the control accuracy higher.

l Reasonable design, evenly the force, effectively improve the water jet operating life and reliability.

CNC Water Jet Cutting Machine Manufacturers

Choosing a quality AB 5-axis waterjet cutting machine manufacturer is of utmost importance due to several key reasons:

Machine Performance and Reliability

Reputable waterjet cutting machine manufacturers will prioritize quality in the construction and components of their machines. This ensures that the AB 5-axis waterjet cutting machine operates with optimal performance, delivering accurate cuts, smooth motion control, and reliable operation over extended periods.

Cutting Precision and Accuracy

A reliable manufacturer will have stringent quality control measures in place during the production process. The consistency and reliability of the machine's performance are crucial for achieving high-quality cuts and intricate designs, especially in industries such as aerospace, automotive, and stone processing.

Longevity and Durability

Investing in a quality AB 5-axis waterjet cutting machine from a reputable manufacturer ensures its longevity and durability. Quality machines are built with robust materials and undergo rigorous testing to withstand the demanding nature of industrial operations. This translates to a longer lifespan for the machine, reducing the need for frequent repairs or replacements and providing a solid return on investment.

In conclusion, partnering with a quality AB 5-axis waterjet cutting machine manufacturer is a vital consideration for businesses looking to maximize the efficiency and effectiveness of their waterjet cutting operations.

|

Model |

YD-1212 |

YD-2015 |

YD-2515 |

YD-3015 |

YD-3020 |

YD-4020 |

|

|

Structure |

Flying-arm |

Flying-arm |

Flying-arm |

Flying-arm |

Bridge |

Bridge |

|

|

Cutting table size |

1300×1300mm |

2100×1600mm |

2600×1600mm |

3100×1600mm |

3100×2100mm |

4100×2100mm |

|

|

Stroke |

X-axis |

1200mm |

2000mm |

2500mm |

3000mm |

3000mm |

4000mm |

|

Y-axis |

1200mm |

1500mm |

1500mm |

1500mm |

2000mm |

2000mm |

|

|

Z-axis |

100mm |

||||||

|

A-axis |

±10° |

||||||

|

B-axis |

±10° |

||||||

|

CNC controller |

AC servo system |

||||||

|

Accuracy |

Cutting |

±0.1mm |

|||||

|

Repeatability |

±0.05mm |

||||||

|

Traverse speed |

6000∕15000mm∕min |

||||||

|

Power supply |

220V∕380V∕415VAC,50∕60HZ |

||||||

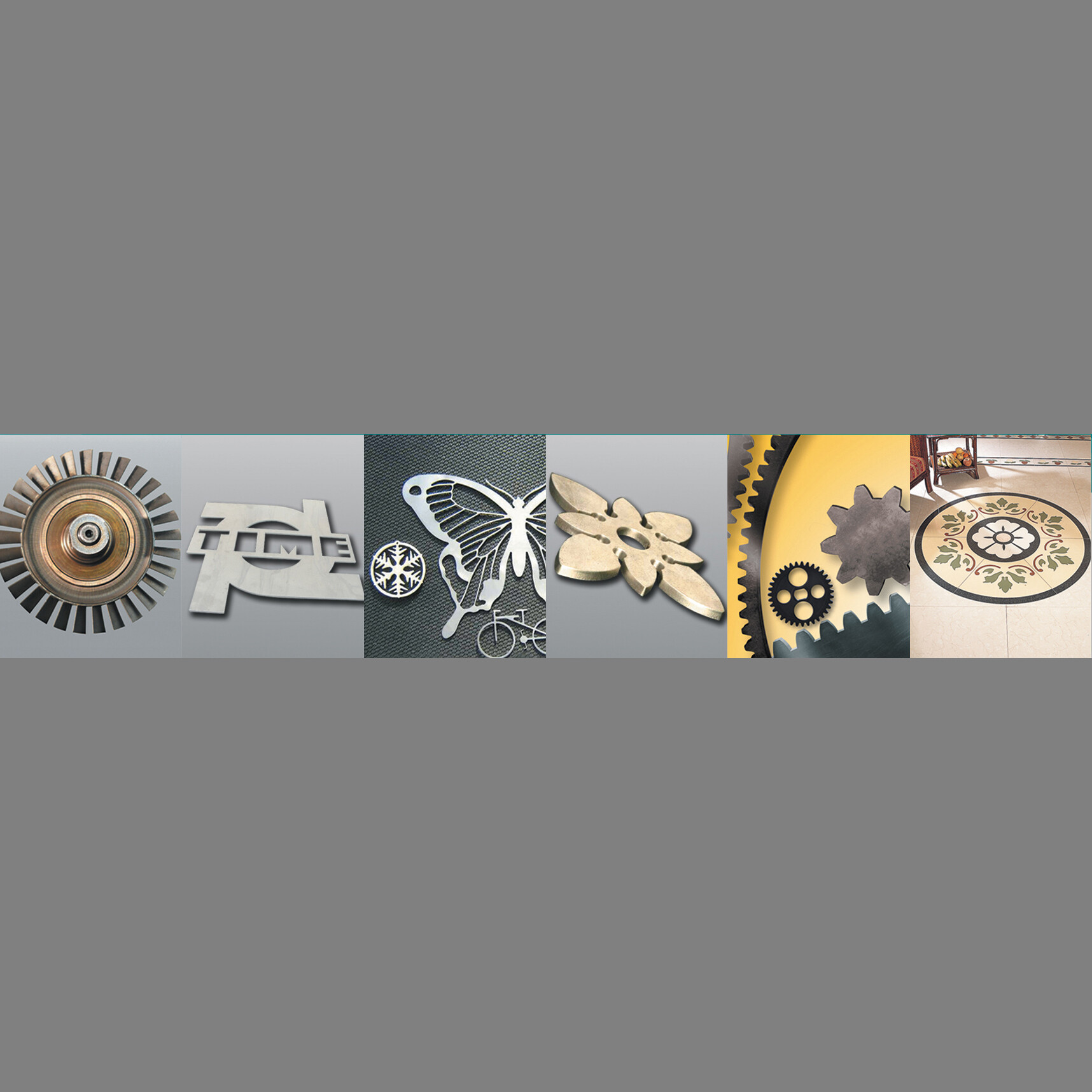

The AB 5-axis waterjet cutting machine is a versatile tool used in various industries for the precision cutting of a wide range of materials.

Here are some applications where the AB 5-axis waterjet cutting machine is commonly used:

● Aerospace Industry

● Automotive Industry

● Architectural Applications

● Manufacturing and Fabrication

● Marine Industry

Electronics Industry

Renewable Energy Sector

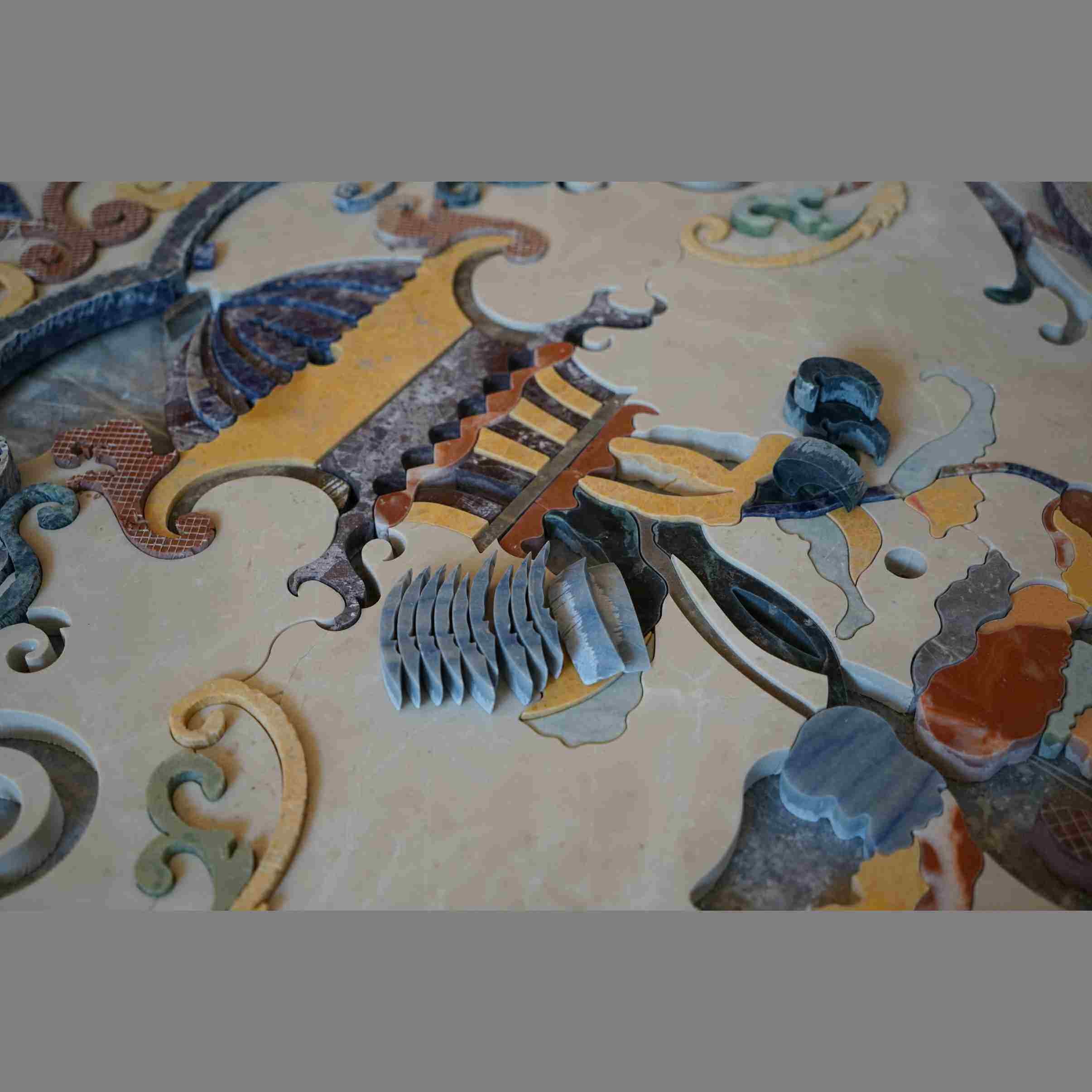

Application of Ab 5 Axis Waterjet Cutting Machine in Stone Process

AB 5 Axis Waterjet Cutting Machine is the best solution for making stone patterns, and stone designs.

The AB 5-axis waterjet cutting machine is widely used in the stone processing industry due to its ability to cut and shape various types of stone materials with high precision. Here are some specific applications of the AB 5-axis waterjet cutting machine in the stone process:

● Stone Countertops and Surfaces

The 5 axis CNC waterjet is used to cut stone slabs into precise dimensions for countertops, tabletops, and other surface applications. It can create intricate designs, curves, and edge profiles on materials such as granite, marble, quartz, and engineered stone.

● Decorative Stone Inlays

The AB 5-axis waterjet cutting machine is employed to create intricate inlays and decorative patterns on stone surfaces. It can accurately cut out intricate shapes, logos, and designs, which are then fitted into larger stone pieces or assembled to form complex mosaic patterns.

● Architectural Elements

AB 5 axis waterjet cutting machine is utilized to cut stone materials for architectural applications, including exterior and interior cladding, wall panels, flooring, and decorative elements. It enables the precise cutting of stone to achieve custom shapes, sizes, and patterns required for architectural designs.

● Monument and Memorial Engravings

The AB 5-axis waterjet cutting machine is used to engrave intricate designs, names, dates, and other details on stone monuments and memorials. It allows for detailed and precise engraving on various types of stones used in memorials, grave markers, and plaques.

● Stone Sculptures and Artwork

Artists and sculptors utilize the machine to cut and shape stone for creating sculptures, statues, and artwork. It enables the realization of intricate and complex designs with precise cutting, allowing artists to bring their visions to life.

● Restoration and Repair

5 axis CNC waterjet is valuable for stone restoration projects, where damaged or deteriorated stone elements need to be replaced or repaired. It can accurately cut stone pieces to match existing profiles and dimensions, ensuring seamless integration with the original structure.

● Stone Tile Production

The AB 5-axis waterjet cutting machine is employed in the production of stone tiles for flooring, walls, and other applications. It can cut large stone slabs into precise tile sizes, create custom tile shapes, and make intricate patterns, providing versatility in tile design.

The AB 5-axis waterjet cutting machine revolutionizes the stone processing industry by offering precise, efficient, and versatile cutting capabilities. Its use in stone processing applications enables the creation of intricate designs, custom shapes, and precise cuts on various stone materials, enhancing the possibilities for architectural, decorative, and artistic projects.