In the stone processing industry, achieving intricate designs and precise cuts is essential for delivering high-quality products. A stone pattern cutting machine is the key to enhancing efficiency, accuracy, and productivity in stone fabrication. Whether you are working with marble, granite, quartz, or other natural and engineered stones, investing in an advanced cutting machine can significantly improve your business operations.

Stone Pattern Cutting Machine

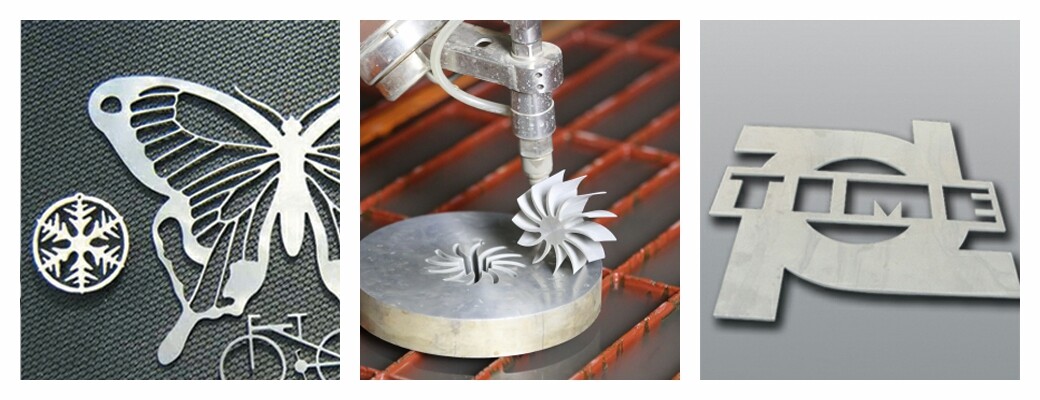

A stone pattern cutting machine is a specialized piece of equipment designed to cut and shape stones into specific patterns, designs, and sizes. Using advanced CNC (Computer Numerical Control) technology, water jet cutting, or laser precision, these machines offer unparalleled accuracy, ensuring that every cut meets exact specifications.

These machines are widely used in various applications, including:

Architectural stonework – creating intricate decorative designs for buildings

Countertops and tabletops – ensuring precise cuts for seamless installation

Tile and flooring production – cutting custom shapes and patterns

Sculptures and monuments – crafting detailed stone designs

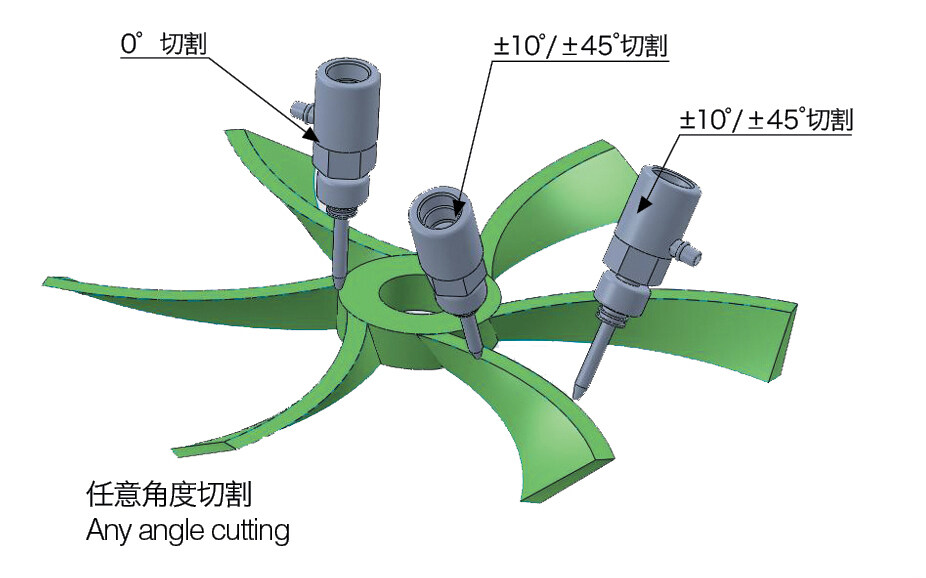

AC 5 Axis Waterjet Cutting Machine

Why Invest in a Stone Pattern Cutting Machine?

Investing in a high-quality stone pattern cutting machine can elevate your business by enhancing efficiency, reducing costs, and improving product quality. Whether you are a stone fabricator, construction company, or interior designer, having a reliable cutting machine ensures that you meet client demands with precision and professionalism.

Key Features and Benefits of Stone Pattern Cutting Machine

High Precision and Accuracy: Stone pattern cutting machines are engineered to deliver high-precision cuts, ensuring minimal material wastage. With CNC automation, even the most complex patterns can be executed with flawless accuracy. This is especially beneficial for intricate tile designs, countertops, and artistic stone carvings.

Time and Cost Efficiency: Traditional stone cutting methods are time-consuming and labor-intensive. A computer-controlled cutting machine can significantly reduce labor costs while increasing output. The automated process allows for bulk production with consistent quality, making it an ideal investment for stone processing businesses.

Versatility in Material Processing: Modern stone cutting machines can handle a variety of materials, including marble, granite, limestone, travertine, quartz, and artificial stones. This versatility makes them suitable for diverse applications, from home renovations to large-scale commercial projects.

Customizable Cutting Options: With advanced software integration, users can design and customize stone patterns according to project requirements. The ability to import CAD files and execute complex cuts gives designers and architects unlimited creative possibilities.

Reduced Waste and Environmental Benefits: Stone pattern cutting machines use precision cutting techniques to reduce material wastage. Some models utilize water jet cutting, which is an eco-friendly method that minimizes dust and heat emissions.

Choosing the Right Stone Pattern Cutting Machine

When selecting a stone pattern cutting machine, consider the following factors:

Cutting Technology: CNC routers, water jet cutters, and laser cutting machines each have their advantages. Choose one that suits your specific needs.

Size and Capacity: Ensure the machine meets your production volume and workspace requirements.

Software Compatibility: Look for a model that supports CAD/CAM software for seamless design integration.

Durability and Maintenance: Opt for a machine with a robust frame and easy maintenance features to ensure long-term performance.

FAQs About Stone Pattern Cutting Machines

What is a stone pattern cutting machine?

A stone pattern cutting machine is a specialized piece of equipment used to cut and shape stones into intricate patterns and designs. It uses CNC, water jet, or laser technology to ensure high precision and efficiency in stone processing.

What types of stone can a pattern cutting machine work with?

Most stone cutting machines can handle a variety of materials, including:

Natural stones: Marble, granite, limestone, travertine, sandstone

Engineered stones: Quartz, sintered stone, artificial stone

Other materials: Ceramic tiles, glass, and concrete

What are the main advantages of using a stone pattern cutting machine?

● High precision and accuracy for detailed cuts

● Increased production efficiency and reduced labor costs

● Versatility in handling different stone types and designs

● Customizable cutting options through CAD software integration

● Minimal material waste, making it an eco-friendly choice

How does a CNC stone pattern cutting machine work?

A CNC (Computer Numerical Control) stone cutter operates by following a pre-programmed design. The machine moves the cutting tool based on precise coordinates, ensuring consistent and accurate cuts with minimal human intervention.

What’s the difference between a CNC router and a water jet cutter for stone cutting?

CNC Routers: Use rotating tools to carve and cut stone, ideal for engraving and shaping.

Water Jet Cutters: Use high-pressure water mixed with abrasives to cut through tough materials; perfect for intricate patterns and delicate stones.

Is a stone pattern cutting machine suitable for small businesses?

Yes! Many manufacturers offer compact and affordable models designed for small workshops. Investing in a pattern cutting machine can increase production capacity, reduce waste, and improve design precision, giving small businesses a competitive edge.

Do I need special training to operate a stone pattern cutting machine?

Most modern machines come with user-friendly software that allows for easy design input and automatic cutting. However, basic training in CAD software and machine operation is recommended to ensure optimal performance.

How much does a stone pattern cutting machine cost?

The cost varies depending on the type, size, cutting technology, and features. Entry-level machines can start from a few thousand dollars, while high-end industrial models can cost tens of thousands of dollars.

Where can I buy a high-quality stone pattern cutting machine?

You can purchase from specialized stone machinery manufacturers, industrial equipment suppliers, or online platforms that offer professional-grade machines.

Yongda Stone Pattern Cutting Machine

Get Your Stone Cutting Machine

Are you looking to upgrade your stone processing capabilities? Contact us today to explore our latest stone pattern cutting machines and find the perfect solution for your business. Take your craftsmanship to the next level with cutting-edge technology designed for excellence.