Precision, efficiency, and adaptability are key in modern construction and fabrication. With their ability to create precise angled cuts, Miter cutting machines have become indispensable tools across industries such as architecture, metalworking, and furniture production.

What Makes a Miter Cutting Machine Unique?

A miter cutting machine is specifically designed to cut materials at varying angles, primarily to create joints for structural or decorative purposes. Common materials processed by these machines include wood, aluminum, steel, PVC, and even composite materials. Unlike basic saws, miter cutting machines allow users to adjust the cutting angle precisely—often at 45° or 90°, but also at more complex angles depending on the machine's configuration.

Modern miter saws come in various configurations:

Manual Miter Saws: Best for simple, small-scale projects.

Compound Miter Saws: Enable angled and beveled cuts simultaneously, ideal for crown molding and complex joinery.

Sliding Miter Saws: Feature sliding arms for cutting wider materials, suitable for larger workpieces like beams and wide boards.

CNC-Driven Miter Saws: Automated systems for high-volume, precise industrial production.

Applications of Miter Cutting Machines in Construction and Fabrication

Structural Construction

In structural construction, miter cutting machines are used extensively for cutting metal beams, pipes, and wooden components to specific angles. For example, when erecting a steel-framed building, the connection points between beams often require angled cuts to ensure a secure and seamless fit. Sliding miter saws with powerful blades can handle large steel beams, making them critical for creating frameworks in both residential and commercial buildings.

Metal Fabrication for Industrial Use

In industries such as automotive manufacturing, aerospace, and heavy equipment production, precision-cut metal parts are crucial. Miter cutting machines equipped with carbide-tipped blades or abrasive wheels allow manufacturers to cut metal tubing or bars accurately for brackets, machine frames, and custom assemblies. CNC miter saws are particularly valuable here, enabling programmable, repeatable cuts that meet tight tolerances.

Interior and Exterior Finishing

Interior projects like installing crown molding, baseboards, or window casings require exact miter cuts to achieve clean, professional joints. Exterior applications include cutting trim or siding materials, where accuracy ensures water resistance and aesthetic appeal. Compound miter saws, which allow for dual-angle adjustments, are a staple in carpentry for such detailed work.

Furniture Production

High-quality furniture requires precise joinery, especially for angled components like table legs, chair backs, or decorative frames. Miter saws enable craftsmen to create flawless joints without gaps, ensuring durability and visual consistency. In large-scale furniture manufacturing, CNC miter saws are often integrated with automation systems for mass production while maintaining exacting standards.

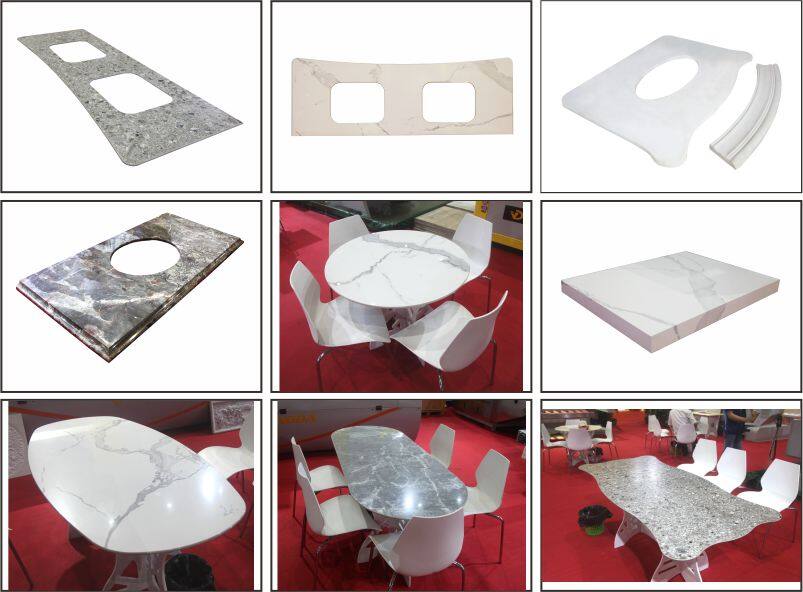

Stone and Tile Fabrication

Specialized miter saws with diamond-coated blades are used in the construction of countertops, flooring, and decorative stone features. For instance, when fabricating a marble countertop, a miter cut is often necessary to create seamless corner joints. These machines are essential in ensuring precise angles, especially for high-end custom projects.

Advantages of Using Miter Cutting Machines

High Precision and Repeatability

Whether cutting metal pipes for an industrial assembly or trimming delicate moldings for interior design, miter cutting machines ensure precise angles every time. Advanced models, like those equipped with CNC, can execute the same cut repeatedly with negligible deviation, critical for mass production.

Material Versatility

Miter cutting machines can handle a wide array of materials. For example:

Wood: Common for carpentry and interior decoration.

Metal: Aluminum, stainless steel, or mild steel for construction and manufacturing.

PVC/Plastic: Used in plumbing and lightweight construction components.

Stone: Marble, granite, or quartz for architectural and decorative elements.

Efficiency in Production

Time is money in construction and fabrication. Miter saws with sliding or dual-bevel capabilities drastically reduce setup time, allowing workers to handle more tasks in less time. Fully automated machines with material feeders can cut dozens of pieces in minutes, increasing throughput while minimizing labor costs.

Enhanced Safety

Modern miter cutting machines are equipped with safety features like blade guards, dust collection systems, and emergency stop mechanisms. These not only protect operators but also ensure a cleaner and safer workspace.

Cost-Effective Solutions

By reducing material waste and improving productivity, miter cutting machines offer a significant return on investment. Their durability and reliability make them a smart long-term investment for professionals in construction and fabrication.

Miter Cutting Machines in Aluminum Door and Window Production

In the aluminum door and window industry, miter cutting machines are indispensable. The frames of doors and windows must be cut at precise angles—usually 45°—to ensure tight and seamless joints. Sliding compound miter saws or CNC miter saws are used to achieve this. With automation, aluminum door and window manufacturers can produce hundreds of frames daily with consistent accuracy, meeting the demand for modern, energy-efficient, and visually appealing window systems.

Conclusion

Miter cutting machines have transformed the construction and fabrication landscape by offering unmatched precision, versatility, and efficiency. From structural frameworks to intricate furniture designs, their applications are diverse and indispensable. As industries increasingly prioritize speed, quality, and cost-effectiveness, miter cutting machines continue to evolve, incorporating advanced technologies like CNC programming and eco-friendly features.

For professionals and manufacturers alike, investing in the right miter cutting machine is essential for staying competitive. With their ability to deliver consistent, high-quality results across various materials and projects, these machines remain at the forefront of modern construction and fabrication practices.