Categorys

Hot Product

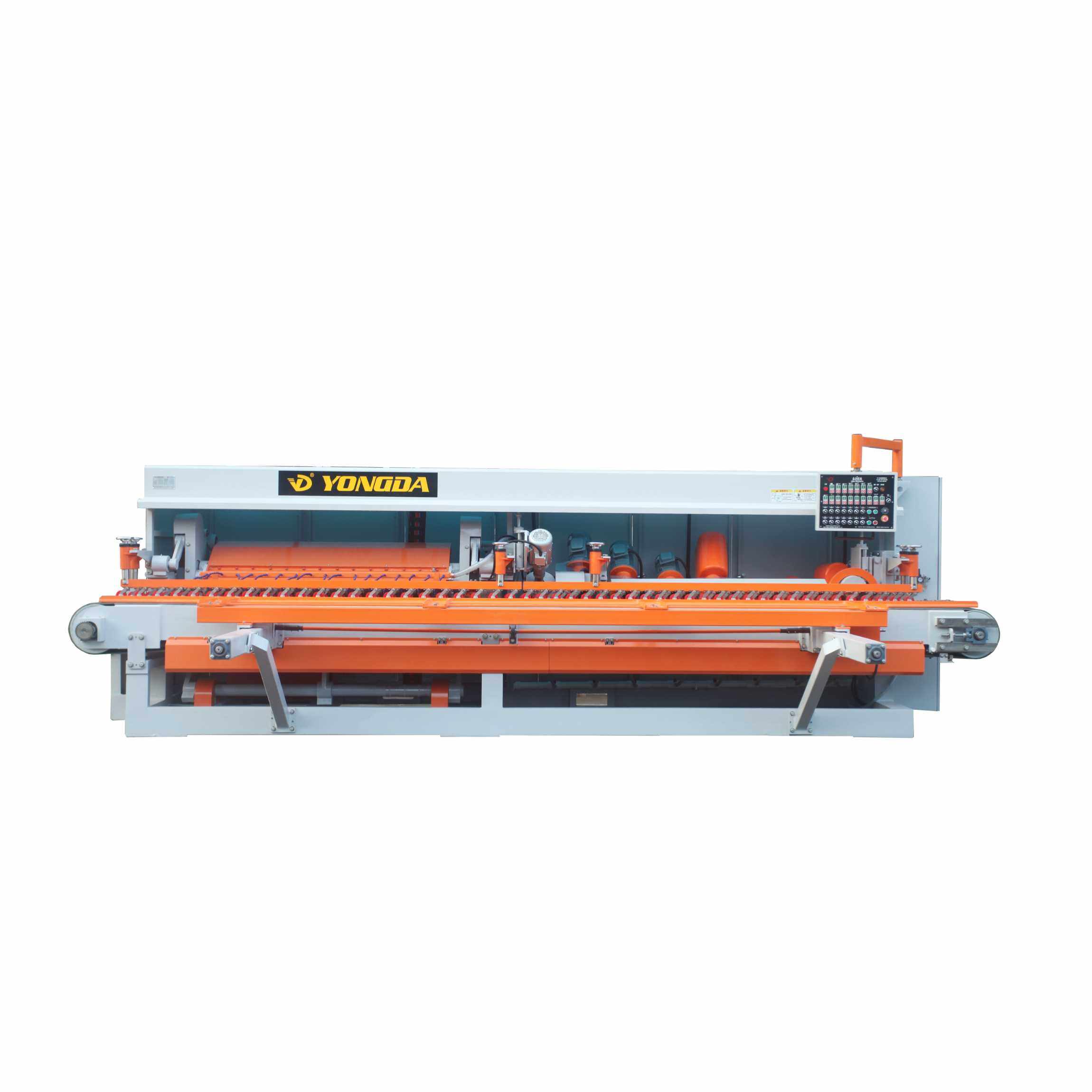

Ceramic arc edge polishing machine

Earliest product in the domestic industry and fastest obtain customer’s recognition and trust.

More than 20 years experience on the machine, keeps improving our products. Using high precision machine and good material to processing the spare parts.

Specialized assembling and strict quality control.

Easy and efficiency operation.

YONGDA 14 heads ceramic arc edge polishing has edge cutting, notching, chamfering, polishing and so on functions. It can process various edges such as 90 degree arc edge, straight and bevel edge, straight edge with chamfering, arc edge with notching etc. Polishing parts use 14 polishing heads, efficiency, shine polishing, steady quality for edge polishing. With fast processing speed, low processing cost, various edges, YONGDA ceramic arc edge polishing machine is highly appreciated by new and old customers.

|

Items |

Unit |

YH-1200 |

|

Nos of conveying belt |

PCS |

1 |

|

Nos of polishing head |

PCS |

14 |

|

Dia of the polishing head |

mm |

Ф100 |

|

Nos of chamfering wheel |

PCS |

7 |

|

Dia of chamfering wheel |

mm |

Ф150~Ф200 |

|

Nos of notching disc |

PCS |

3~4 |

|

Dia of notching disc |

mm |

Ф150 |

|

Nos of pneumatic chamfering head |

PCS |

1 |

|

Dia of pneumatic chamfering head |

mm |

Ф100 |

|

Nos of drying meatus |

PCS |

1 |

|

Working width |

mm |

70~1200 |

|

Polishing speed |

m/min |

2~10 |

|

Working thickness |

mm |

6~20 |

|

Total power |

kw |

37 |

|

Water consumption |

L/min |

490 |

|

Air consumption |

L/min |

55 |

|

Outer dimension |

mm |

8250×3050×1680 |

|

Weight |

T |

≈5.5 |

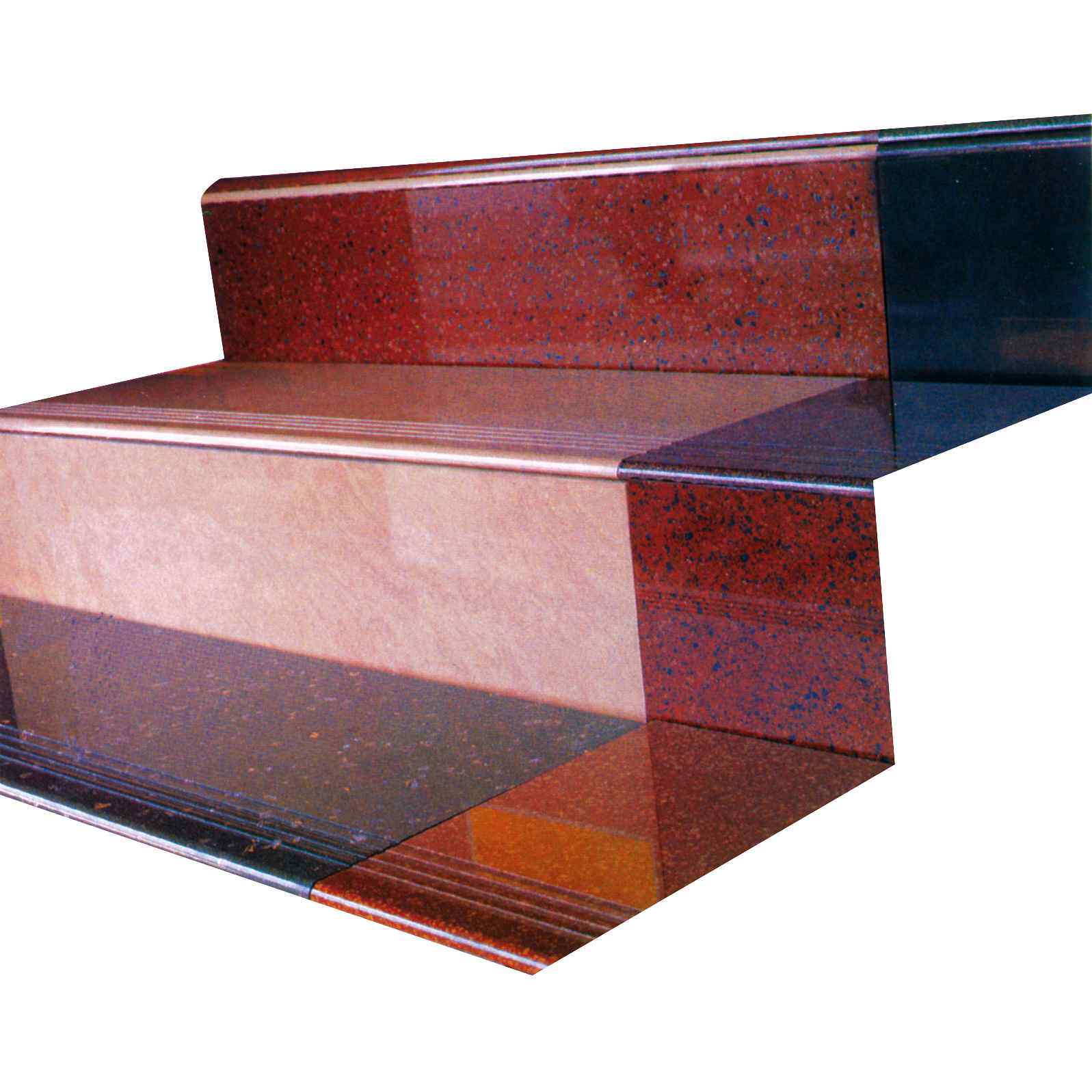

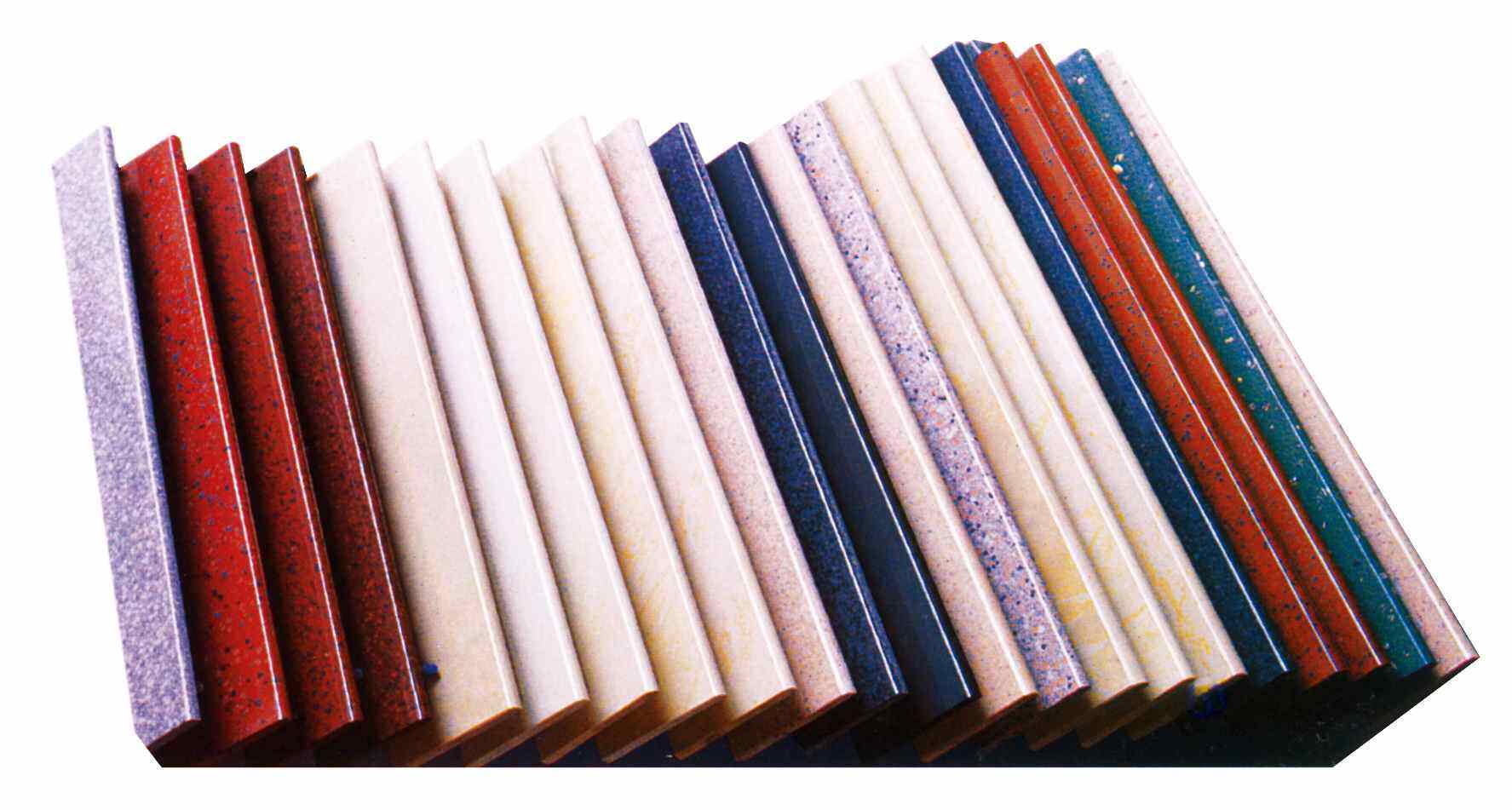

Suitable industry: suitable for ceramic processing industry. For step tiles processing, window tiles processing, metope waist line etc.\