Categorys

Hot Product

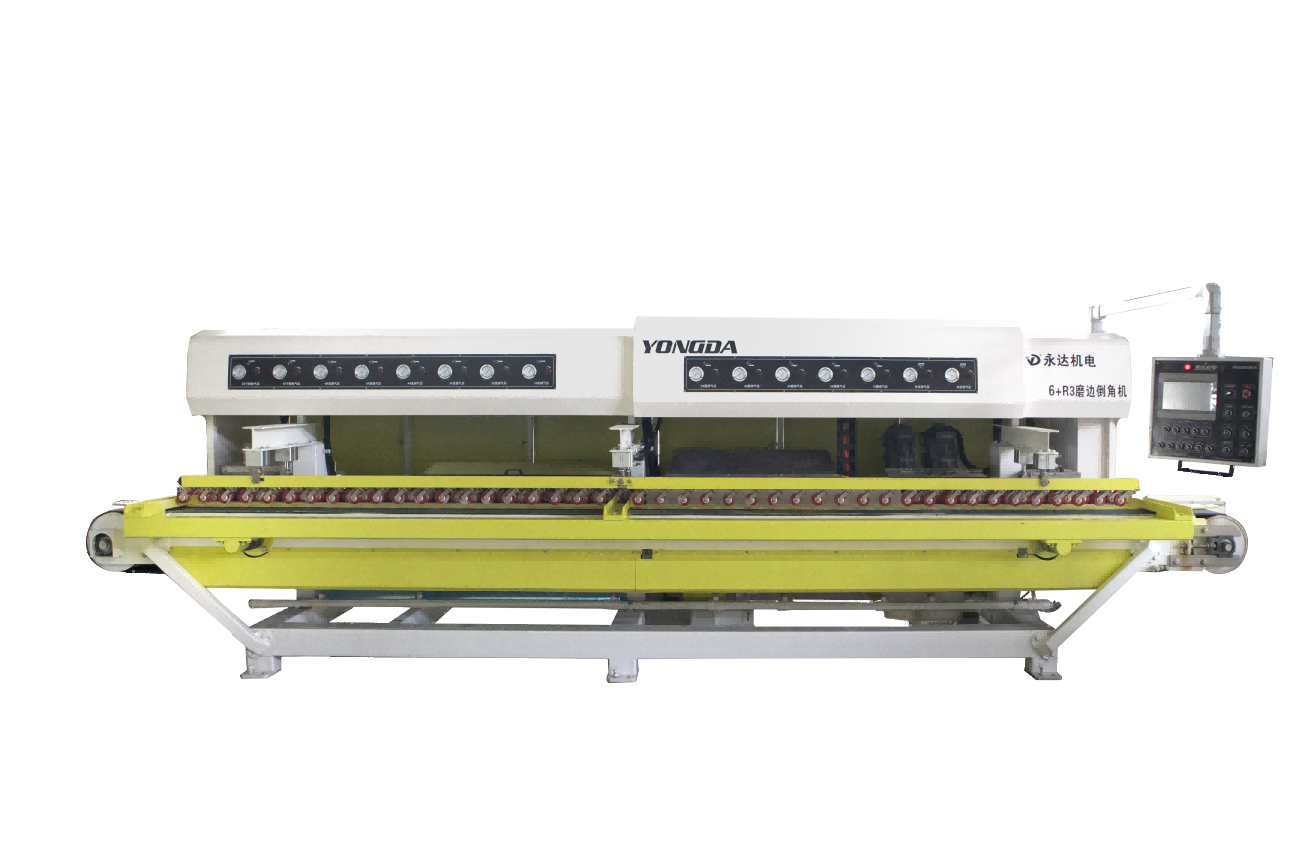

6+R3 Edge Grinding & Chamfering Machine

Sinterd stone edge processing machine

what kind of edge processing you can do with this machine?

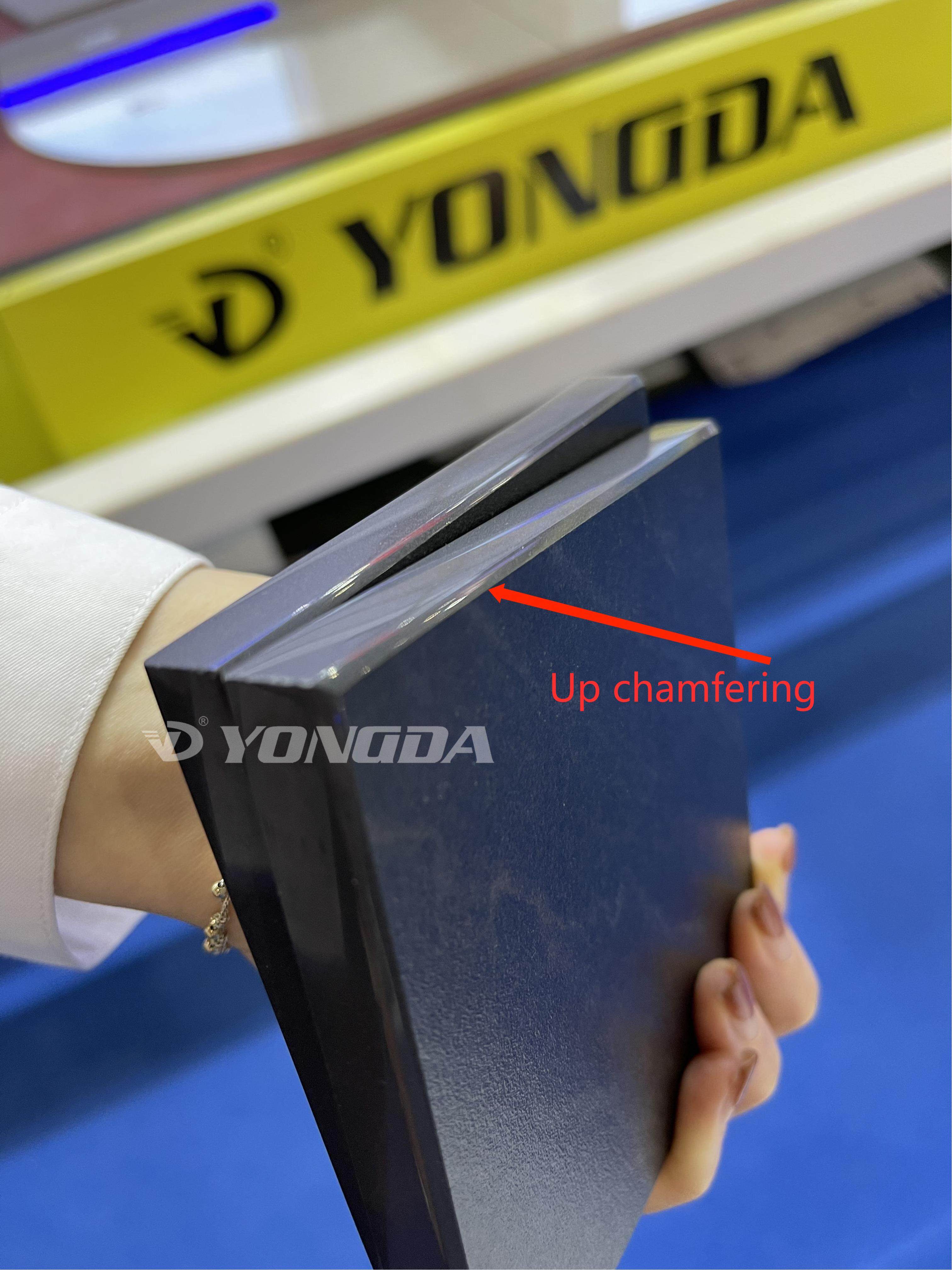

1. R3 edge grinding and polishing

2. Edge 45 chamfering

3. Straight flange grinding and polishing

4. Safe edge grinding and polishing of the bottom and the top of the edge

This machine is for edge grinding and chamfering polishing (R1~R5 arcs, straight flange, bevels) and grooving of sintered stone. Fast speed, high efficiency, high precision, high brightness, even straightness and smooth.

Suitable for sintered stone, porcelain, ceramic grinding edge chamfering, cabinet processing.

|

MODEL |

UNIT |

YD-PG-6+R3 |

|

Processing slab width |

mm |

120~1200 |

|

Processing slab thickness |

mm |

15~40 |

|

Working speed |

m/min |

0.4~2 |

|

Total power |

kw |

36 |

|

Water consumption |

L/min |

150 |

|

Air condition |

L/min |

140 |

|

Weight |

t |

5 |

|

Outer dimension |

m |

7.8×1.7×2 |

|

Conveyor belt |

pc |

1 (width: 600) |

|

Trimming wheel |

pc |

1 pcs,Ф250*Ф80,4kw |

|

The bottom edge chamfering |

pc |

1 disc Ф300*Ф50 (4kw) +1 grinding wheel Ф250*Ф80 (4kw) |

|

Polishing wheel of straight and bevel edge |

pc |

6+6 pcs,Ф120,0.75kw*12 |

|

The top edge chamfering |

pc |

1 disc Ф300*Ф50 (4kw) +1 grinding wheel Ф250*Ф80 (4kw) |

Suitable for sintered stone, porcelain, ceramic grinding edge chamfering, cabinet processing.

The 6+R3 edge grinding & chamfering machine is a specialized equipment designed for the precise grinding, polishing, and chamfering of edges on various materials such as sintered stone, porcelain, and ceramic. This machine is specifically tailored to cater to the needs of industries involved in stone fabrication, tile manufacturing, and cabinet processing.

Versatile Edge Processing: The machine offers multifunctional capabilities, allowing it to handle different types of materials commonly used in construction and interior design. It ensures precision in grinding and chamfering to achieve desired edge finishes.

Sintered Stone and Porcelain Compatibility: Sintered stone and porcelain are notoriously hard materials, requiring specialized equipment for processing. The 6+R3 machine is equipped to handle the hardness of these materials, ensuring efficient grinding without compromising their integrity.

Ceramic Edge Refinement: Ceramic materials, often used in various applications, need delicate handling during edge refinement. This machine provides the necessary precision and control to create smooth and flawless edges on ceramic surfaces.

Cabinet Processing: In addition to handling stone and tile materials, the machine caters to cabinet processing needs. It can efficiently chamfer edges of cabinet components, providing a professional finish for furniture and cabinetry.

Customizable Chamfering Options: The equipment allows for customizable chamfering angles and dimensions, providing flexibility to meet diverse project requirements and design preferences.