Categorys

Hot Product

Stone 180 degree arc edge polishing machine

The YH-180 Arc-edge Grinding and Polishing Machine is the new product which is developed by our company.

Its a great breakthrough compare with our original arc-edge polishing machine which just can polish 1 / 4 (90 ) arc-edge. This Arc-edge Grinding and polishing Machine can extend to Polish 1 / 2 (180 ), extend the processing scope.

It can process half-round table-board and thickly step-board. Its fully automatic to process the straight edge,bevel edge and arc edge.

Its processing thickness can reach 5cm,even the boards with different widths can be processed continuously. Up to now,this machine is highly acknowledged in the stone deep processing industry.

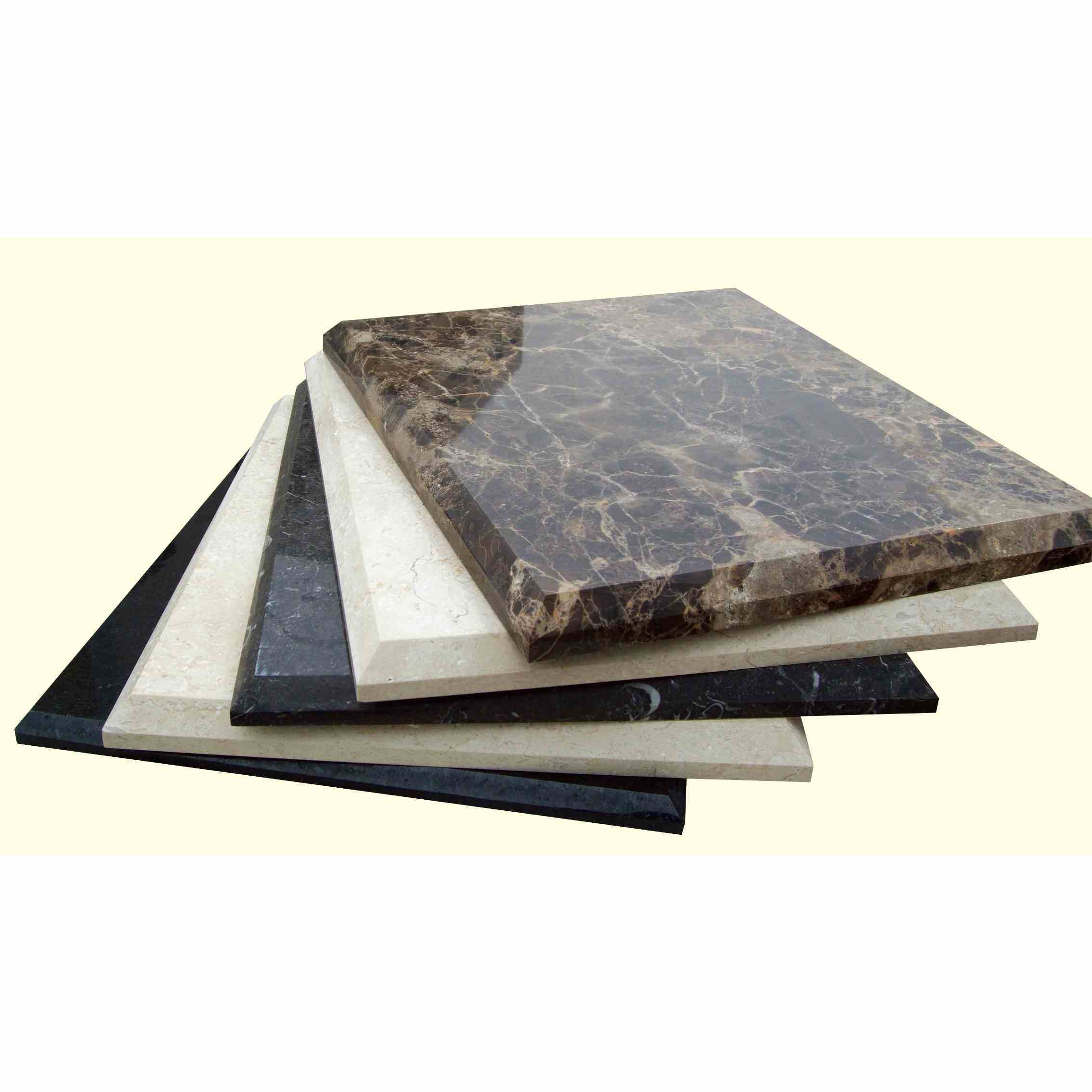

A stone 180-degree arc edge polishing machine is a specialized piece of equipment used in the stone fabrication industry to create semicircular or bullnose edge profiles on stone surfaces. These machines offer precision, automation, and customization options to achieve the desired edge finish on various types of stone materials. It can be used on various types of stone, including granite, marble, quartz, and engineered stone.

Operators can customize the edge profile by adjusting various parameters in the CNC program, such as the radius of the curve, the degree of polish, and the number of passes. These machines are capable of producing high-quality, consistent edge profiles, ensuring that countertops meet industry standards and customer expectations.

YONGDA stone arc edge polishing machine is famous for good quality.

YONGDA 14 heads stone arc edge polishing has edge grinding, notching, chamfering, polishing, and so on functions.

It can process various edges such as 90 degree arc edge, 180 degree arc edge, straight and bevel edge, straight edge with little chamfering, arc edge with notching, etc.

Polishing parts use 14 polishing heads, efficiency, shine polishing, and steady quality for edge polishing.

With fast processing speed, low processing cost, and various edges, the YONGDA stone arc edge polishing machine is highly appreciated by new and old customers.

Two options for customer choice: integrated machine & separated machine.

|

Items |

Unit |

Separated |

Integrated |

|

Nos of polishing head |

PCS |

12 |

10 |

|

Dia of polishing head |

mm |

120 |

120 |

|

Nos of chamfering wheel |

PCS |

6 |

4 |

|

Dia of chamfering wheel |

mm |

200 |

200 |

|

Working width |

mm |

200~1200 |

200~1200 |

|

Working thickness |

mm |

20~60 |

20~60 |

|

Polishing speed |

m/min |

0.2~1 |

0.2~1 |

|

Water consumption |

L/min |

150 |

150 |

|

Air consumption |

L/min |

80 |

80 |

|

Total power |

kw |

55 |

38 |

|

Outer dimension |

mm |

5.3×2.3×2.2 6.1×2.3×2.2 |

8×2.3×2.2 |

|

Weight |

kg |

≈6000 |

6500 |

Suitable industry: suitable for stone processing industry. For step stone processing, window stone processing, metope waist line, tables, etc.

Stone 180-degree arc edge polishing machines are commonly used in kitchen worktop edge polishing, bathroom vanity tops, and other stone surfaces where a rounded edge profile is desired for both aesthetics and safety.