Categorys

Hot Product

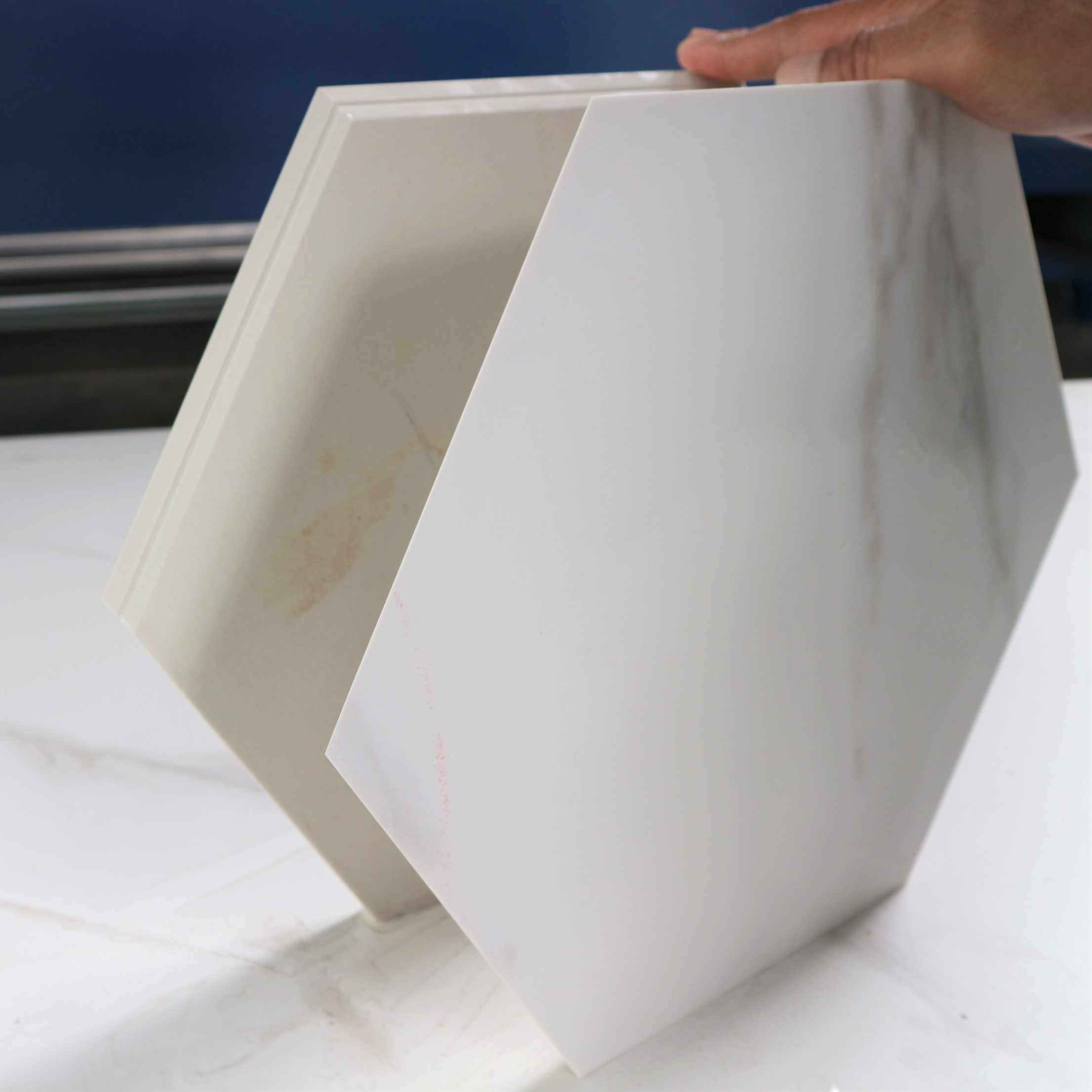

Semi-automatic Sintered Stone chamfering Notching machine

YDJ-3200

Simple design, easy operation, easy maintenance.

Small machine not take too much space.

Semi-automatic Stone chamfering Slotting machine

The machine is for sintered stone, ceramic, stone slab. The processing material is fixed in the machine, cutting by the movement of the cutting tool.

The first cutting head, for 45°pre-cutting.

The second cuttting head, for 45°grinding.

The third cutting head, for the bevel surface slotting.

This machine mainly design for the bathroom tops, ktichentops, stair tiles, background wall (45°chamfering to make 90°joint).

Features and Functionalities of the Sintered Stone Chamfering Notching Machine

Material Adaptability: It's explicitly engineered to work with sintered stone, ceramic, and natural stone slabs, showcasing its versatility across various hard surfaces commonly used in construction, interior design, and architecture.

Chamfering Capabilities: Chamfering involves cutting or grinding a beveled edge, often used for aesthetic purposes or to prevent sharp corners. A porcelain chamfering machine or ceramic tile chamfering machine is to create precise chamfered edges on stone surfaces.

Notching Precision: The sintered stone chamfering notching machine /ceramic tile slotting machine offers high-precision notching, allowing the creation of intricate designs, cuts, or patterns on the stone surfaces. This function is particularly valuable for customized or detailed projects.

Customization Options: Depending on the specific machine model, there might be additional features like adjustable settings for depth, angle, or speed, allowing for customization based on project requirements.

In summary, the sintered stone chamfering notching machine serves as a specialized solution for shaping, detailing, and enhancing the aesthetics of sintered stone, ceramic, and stone slabs. Its precision, adaptability, and durability make it a valuable tool in the construction and design industries, catering to a range of creative and functional applications.

|

MODEL |

UNIT |

YDJ-3200 YD-4020 |

|

Outer Dimension |

mm |

5900 X 1900 X 1600 |

|

Processing Width |

mm |

40~1600 4100×2100 |

|

Processing Length |

mm |

500~3200 3800×2000 |

|

Processing Thickness |

mm |

6~16 |

|

Working Speed |

M/min |

0.5~2 |

|

Chamfering Disc |

PCS |

1PCS,7.5kw , φ300*φ50 |

|

Chamfering grinding wheel倒角磨边轮数量 |

PCS |

2PCS, 4kw*2 , φ200*φ80 |

|

Notching Disc |

PCS |

1 |

|

Notching Disc Diameter |

mm |

Ф150,3kw |

|

Maximum Water Discharge |

L/min |

50 |

|

Maximum Air Consumption |

L/min |

50 |

|

Control |

|

PLC |

|

Power Supply |

V/Hz |

AC220V 380V 415V / 50Hz 60Hz |

|

Total Power |

kw |

20 |

The machine suitable for sintered stone, ceramic, stone slab.

Sintered stone, known for its durability, strength, and resistance to various environmental factors, requires specific machinery that can handle its hardness and density while maintaining accuracy in shaping and detailing. The sintered stone chamfering notching machine is a specialized tool designed for precision cutting, shaping, and finishing of sintered stone, ceramic, and stone slabs.