Categorys

Hot Product

3 Axis Machining center

1. Adopt Italy CNC control system, and servo motor and driver.

2. 15-inch color touch screen, USB, Ethernet Interface.

3. 3 Axis Stone CNC Machine Center equipped with a camera, nesting as a requirement, find machining origin automatically, maximize saving the material, improve processing efficiency.

4. Apply the intelligent polishing control system, greatly improving the polishing quality and efficiency. Simple, easy, low cost, high efficiency.

5. Leading Drawing and Programming Software in the industry, a program with desire drawing.

6. Automatically programming, no need for tool setting, simple and intelligent.

7. Only need a touch, grinding and polishing will start; Grinding, shaping, all-in-one function.

Under the competitive situation,in order to adapt the fierce competition , pursuing high accuracy, high speed, high efficiency modernized processing method,our company has successfully developed and produced CNC processing centre series relying on advanced technical, superior production condition and abundant experience in manufacturing and developing stone processing machinery for many years.

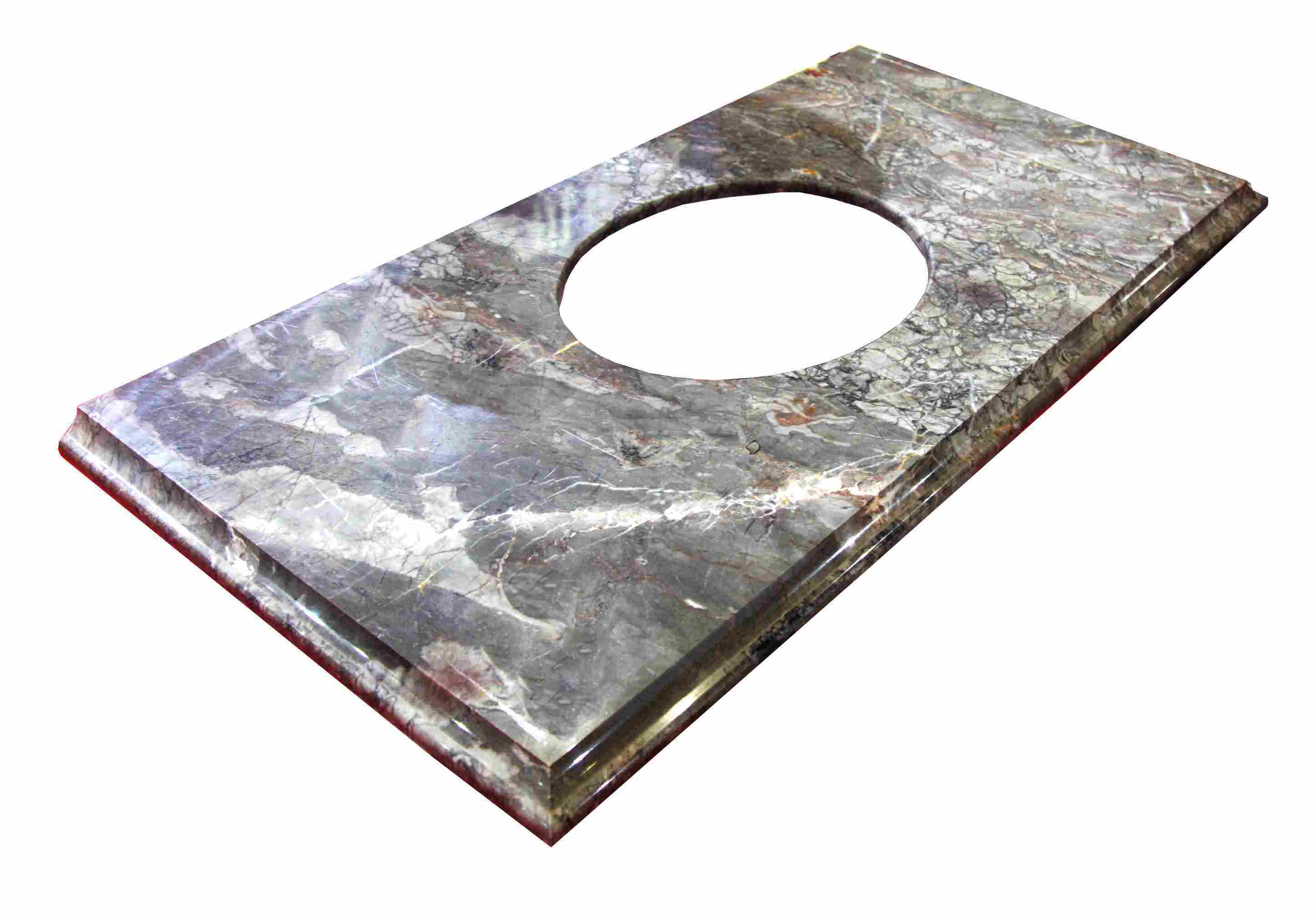

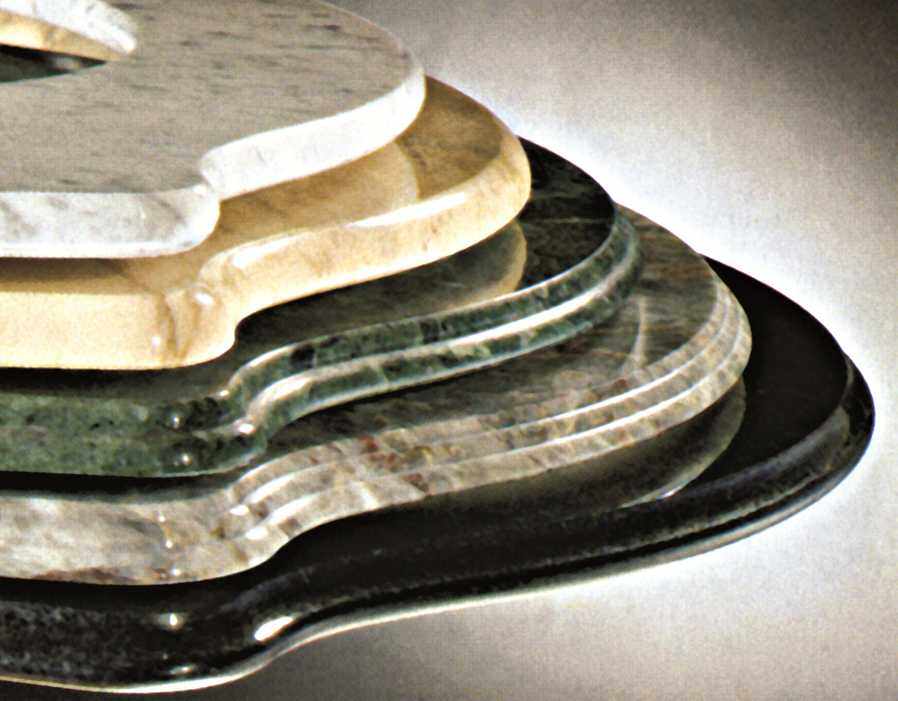

Advanced, multi-functional entire computer numerical control processing center, not only can process various materials, such as granite kitchen table top edge processing, marble kitchen table top edge processing, ceramic, glass, even micro spar and steel, but also can produce various exquisite curve and luxurious model basin board and kitchenware board; As well as various complex relief carving --"YONGDA" series CNC processing center, which provides excellent processing method for classical and modern decoration art.

3 Axis CNC Machining Center

A 3 axis CNC machining center is a computer-controlled machine tool that operates with three axes of motion. It is commonly used in precision machining and manufacturing processes to shape and machine workpieces. 3 axis CNC machining center offers precise and efficient machining capabilities for various industries.

The three axes in a 3-axis machining center are the X-axis, Y-axis, and Z-axis. With these three axes, the machining center can perform various operations such as milling, drilling, and cutting on a workpiece.

Why Is 3 Axis CNC Machining Center Worth Investing In?

There are several advantages to using a 3 axis CNC machining center in precision machining and manufacturing processes. Here are some key benefits:

Versatility

A 3-axis CNC machining center is a versatile machine tool that can perform a wide range of machining operations, including milling, drilling, and cutting. It is suitable for machining both simple and moderately complex parts, making it a valuable asset for various industries.

Cost-effective

Compared to higher-axis machining centers, such as 4-axis or 5-axis machines, a 3-axis CNC machining center is generally more cost-effective. It offers a good balance between functionality and affordability, making it a practical choice for many machining applications.

Ease of use

3-axis CNC machining centers are relatively straightforward to operate. The programming and setup for three axes are generally simpler compared to machines with additional axes. Operators can quickly learn to program and run the machine, reducing training time and increasing productivity.

Quick setup

Setting up a 3-axis CNC machining center is typically faster than setting up machines with more axes. The limited number of axes simplifies the workpiece alignment and fixture setup process, enabling faster turnaround times and increased production efficiency.

Wide availability

3-axis CNC machining centers are widely available in the market, with various sizes and configurations to suit different machining needs. This accessibility makes it easier for businesses to acquire and maintain these machines, ensuring continuity in their manufacturing operations.

Reliable and accurate

3-axis CNC machining centers are known for their reliability and accuracy. The computer-controlled nature of these machines reduces human errors and allows for precise and repeatable machining.

Model Unit CNC 3 - 3020 CNC 3 - 4020 Table dimension mm 3000×2100 3600×2100Processing size mm Grinding:2900×1900 Grinding:3500×1900 Engraving:2900×2000 Engraving:3500×2000Outer dimension mm 6000×3500 6600×3500Z axis stroke mm 380Grinding max. thickness mm 0~80Plane engraving max. thickness mm 0~200Tool store PCS 6+6Spindle power kw 15Spindle speed r/min 12000Cutting water m3/h 4Air consumption 200 L/min 0.6MPaOperating system Italy systemControl method Servo controlPower supply V/Hz AC220V 380V 415V / 50Hz 60HzTotal power kw 26

3 axis CNC machining center is suitable for stone sintered stone, ceramic, countertops, cabinetry, glass etc. industry.

The 3 axis CNC machining center, with its versatility and precision, plays a pivotal role in streamlining manufacturing processes across multiple industries, offering a wide range of applications and contributing to the production of high-quality finished products.

Stone and Sintered Stone Industry

Cutting and Shaping: A 3-axis machining Center is used for precise cutting, shaping, and detailing of natural stones like granite, marble, and sintered stones.

Engraving and Carving: It allows for intricate engraving and carving designs on stone surfaces, adding intricate patterns or custom designs to finished products.

Polishing and Finishing: The 3 axis stone CNC machining center aids in achieving smooth and glossy finishes on stone surfaces, enhancing their aesthetic appeal.

Ceramic Industry

Milling and Profiling: 3 axis CNC machining centers are utilized to mill ceramic materials into various shapes, sizes, and designs as per specific requirements.

Drilling and Hole Making: They're capable of accurately drilling holes and creating cutouts in ceramic pieces, ensuring precision and consistency.

Countertops and Cabinetry

Precision Cutting: In the manufacturing of countertops and cabinetry, these machines are used for precise cutting and shaping of materials like wood, laminates, or engineered stone to meet dimensional specifications.

Customization and Detailing: 3 axis CNC machining center allows for intricate detailing and customization, including edge profiling, carving, and engraving, catering to unique design demands.

Glass Industry

Glass Cutting and Edging: 3 axis CNC machining centers assist in cutting glass sheets with accuracy and precision, along with edging processes to smoothen the edges for safety and aesthetics.

Drilling and Engraving: They can drill holes and create fine engravings on glass surfaces for decorative or functional purposes, such as in glass art or specialized glass products.

General Applications

Prototyping: These stone CNC machining centers are also used in prototyping across industries for creating mock-ups and prototypes of various products before mass production.

Efficiency and Automation: They significantly enhance production efficiency by automating tasks, reducing manual labor, and ensuring consistent quality across manufactured items.