Which YD machine do you need?

Glass is widely used in buildings to make design, keep out wind and light. Also auto industry, art-ware etc. use many glass. Cutting is one of the most common processing steps. What Yongda machines can we used to process glass?

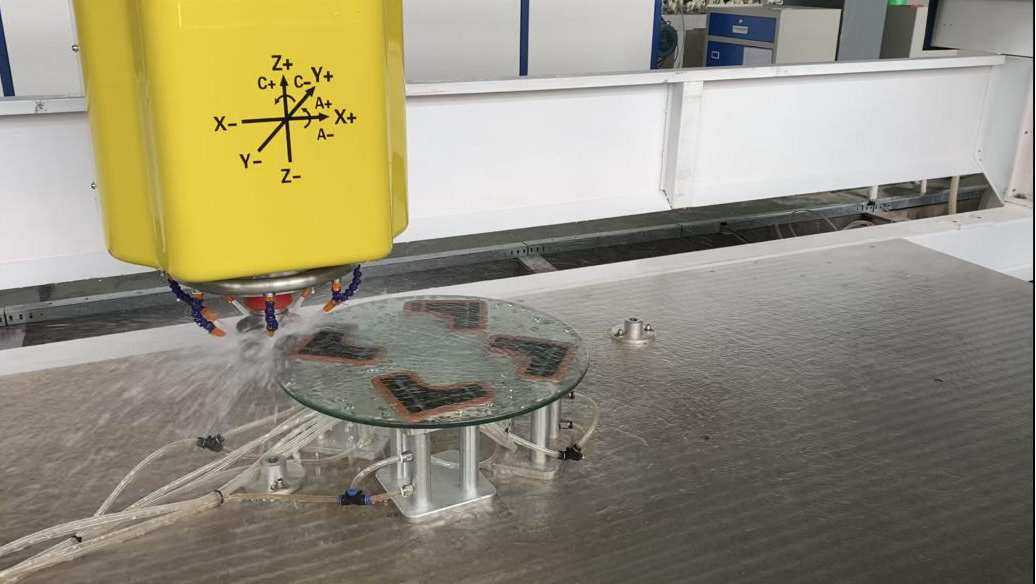

Yongda 3 axis waterjet cutting machine is enough for glass cutting. It is used for any plane curve cutting such as cutting holes, cutting glass in stock board, cutting the art design etc. Waterjet cutting is precision, fast speed and stable which can guarantee all the size is correct and not waste the material. After cutting, surface is neat and smooth so it is a suitable machine for cutting glass.

Waterjet cutting is more flexible. It can cut almost all the material for example metal and stone that if you have other material processing order you can use waterjet to work with it. Furthermore, as the waterjet is cool cutting, it does not damage the materials by the high temperature. It is a good machine for processing plant.

Notice: Waterjet do not cut tempered glass!

What else should we notice? Find a fixture or customize some fixture to fix your glass size, avoiding any move of the slab when cutting.

In addition, when cutting through the materials, the high pressure water will have reflection to the material bottom that the glass may have a scratch mark on it . Therefore, normally we will put some assisting material under the glass for example use some wood sheet to avoid the splash.

Except waterjet,Yongda CNC machining centeralso suitable for glass processing. 3 axis and 5 aixs can do the edge grinding and polishing in one machine. 5 axis can make the relief carving. The optional function, auto change tool, saves the times and cost. Vacuum fix the glass, avoid the glass plate movement.

Choose the glass specific grinding and polishing wheel. When machine the glass, pay attention to the water cooling. Water need to be aligned with the machining wheel.