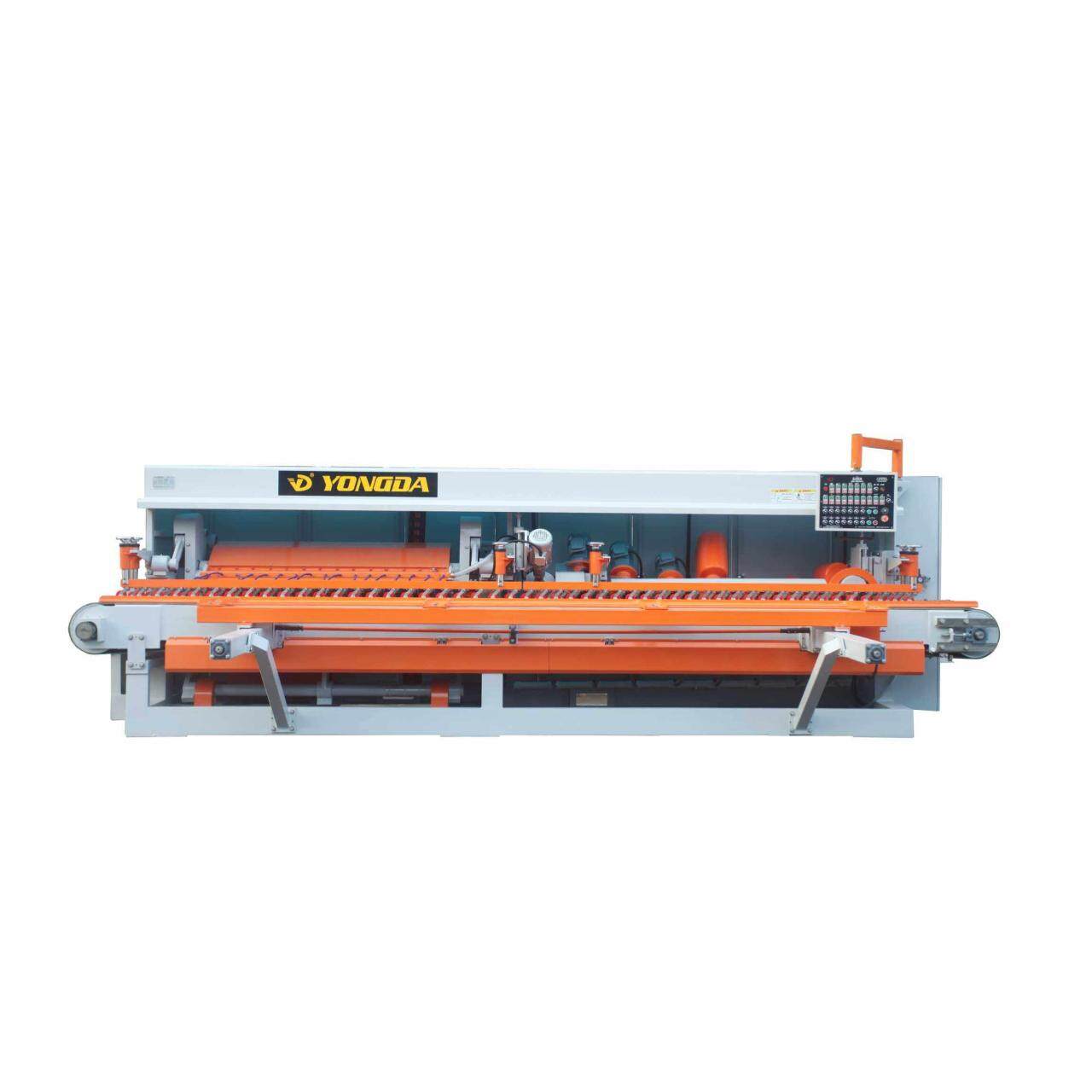

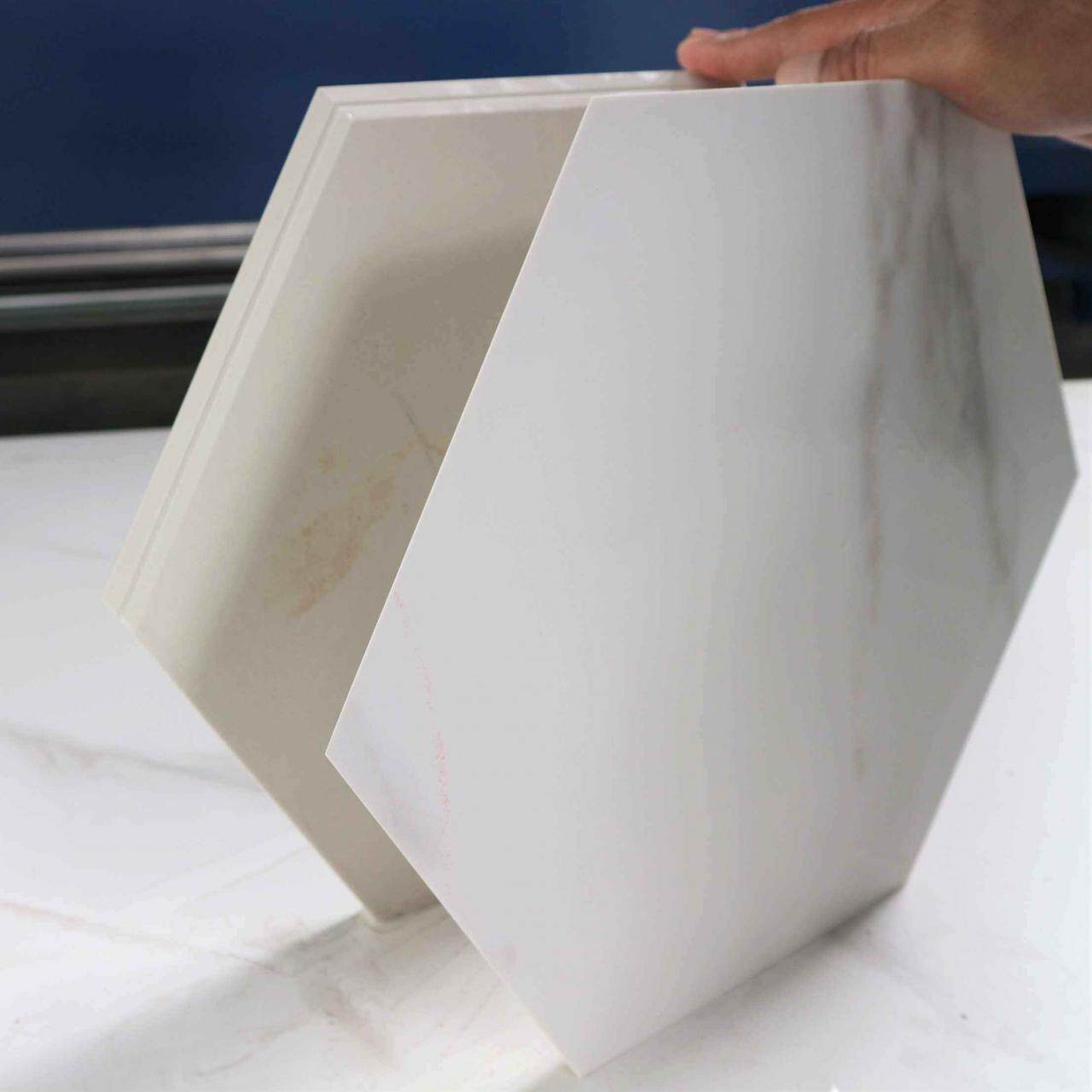

Ceramic arc edge polishing machine

Earliest product in the domestic industry and fastest obtain customer’s recognition and trust. More than 20 years experience on the machine, keeps improving our products. Using high precision machine and good material to processing the spare parts. Specialized assembling and strict quality control. Easy and efficiency operation. YONGDA 14 heads ceramic arc edge polishing has …